An Optimal Quality Control Method for Small Samples Based on Process Capability

A quality control method and technology of small samples, applied in adaptive control, general control system, control/regulation system, etc., can solve the problems of increasing false alarms or taking false alarms, large deviation of results, ignoring the value of small samples, etc. To achieve the effect of improving product quality and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

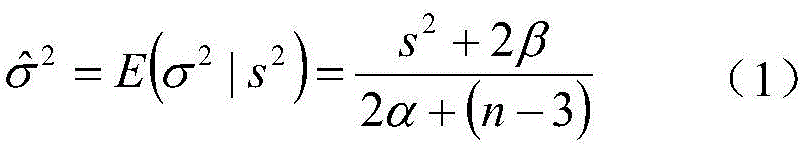

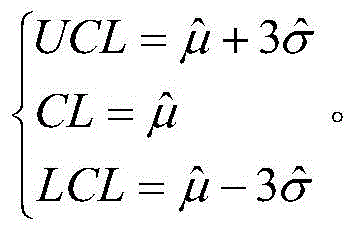

[0026] The present invention relates to a small sample optimal quality control method based on process capability, which is characterized in that it comprises the following steps:

[0027] (1) Determine the objective function: Among them, z is the optimization constraint target value, R is the sample range, T is the standard tolerance set in advance, m is the number of sample groups, is the average range;

[0028] (2) Determine the constraints: For products produced in the same process, their ranges are subject to normal distribution

[0029] Assuming that the number of samples in each group is 4,

[0030] So After being standardized, it obeys the Student's distribution, that is, Then calculate the confidence interval according to the given confidence 1-α;

[0031] When the range is smaller, it indicates that the product is more stable, then when

[0032] A confidence interval is obtained as

[0033] Among them, R is the sample range, S is the standard deviati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com