Method for recognizing rotor crack fault of steam turbine generator unit

A technology for steam turbine generator set and rotor cracks, which is applied in the field of diagnosing crack faults and identifying rotor crack faults of steam turbine generator sets, and can solve problems that affect the accuracy of flaw detection results of flaw detection instruments, are difficult to detect on-site flaw detection, and affect the safe operation of units, etc. , to achieve the effect of preventing catastrophic accidents, avoiding huge economic losses, and avoiding deviations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

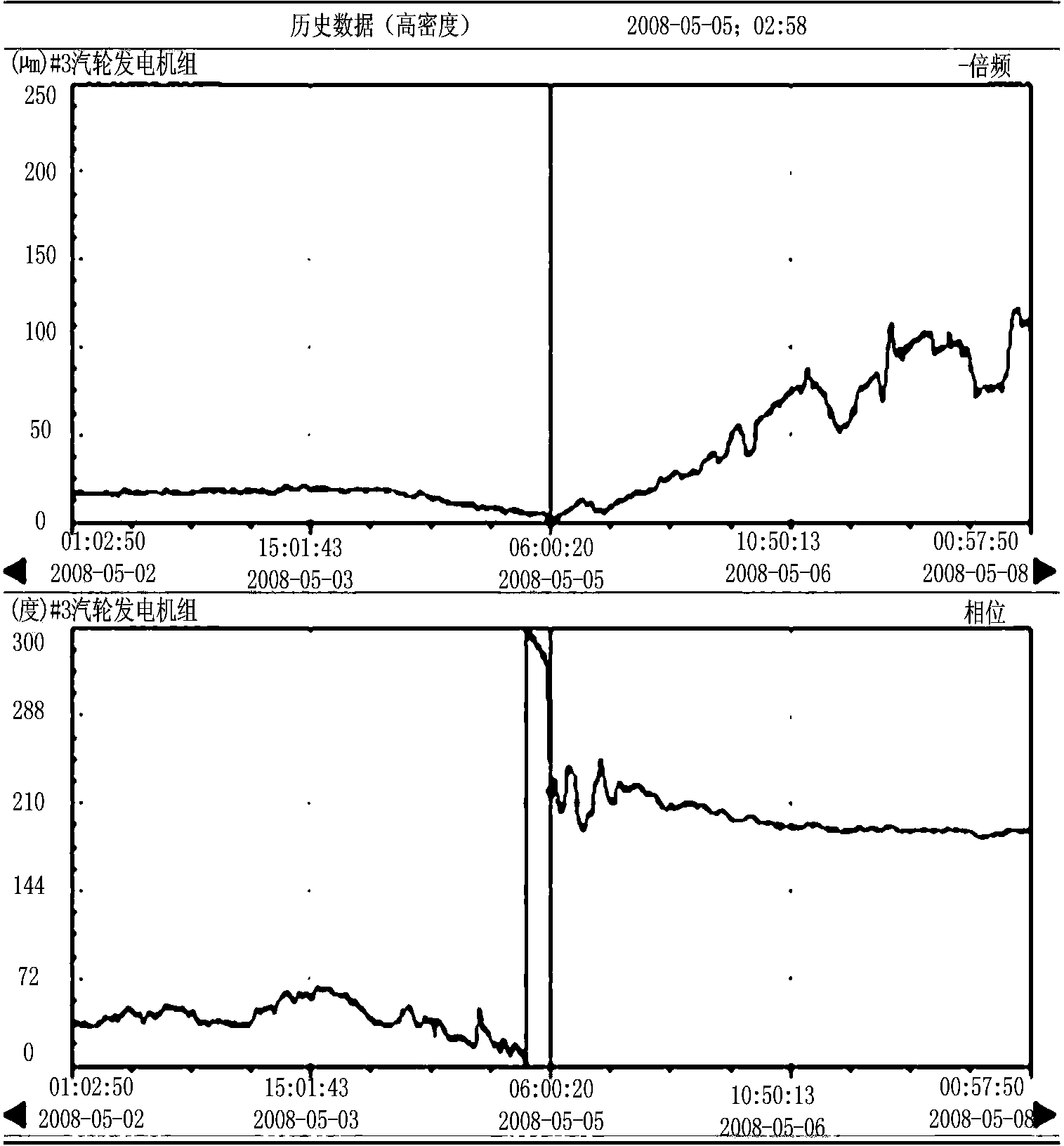

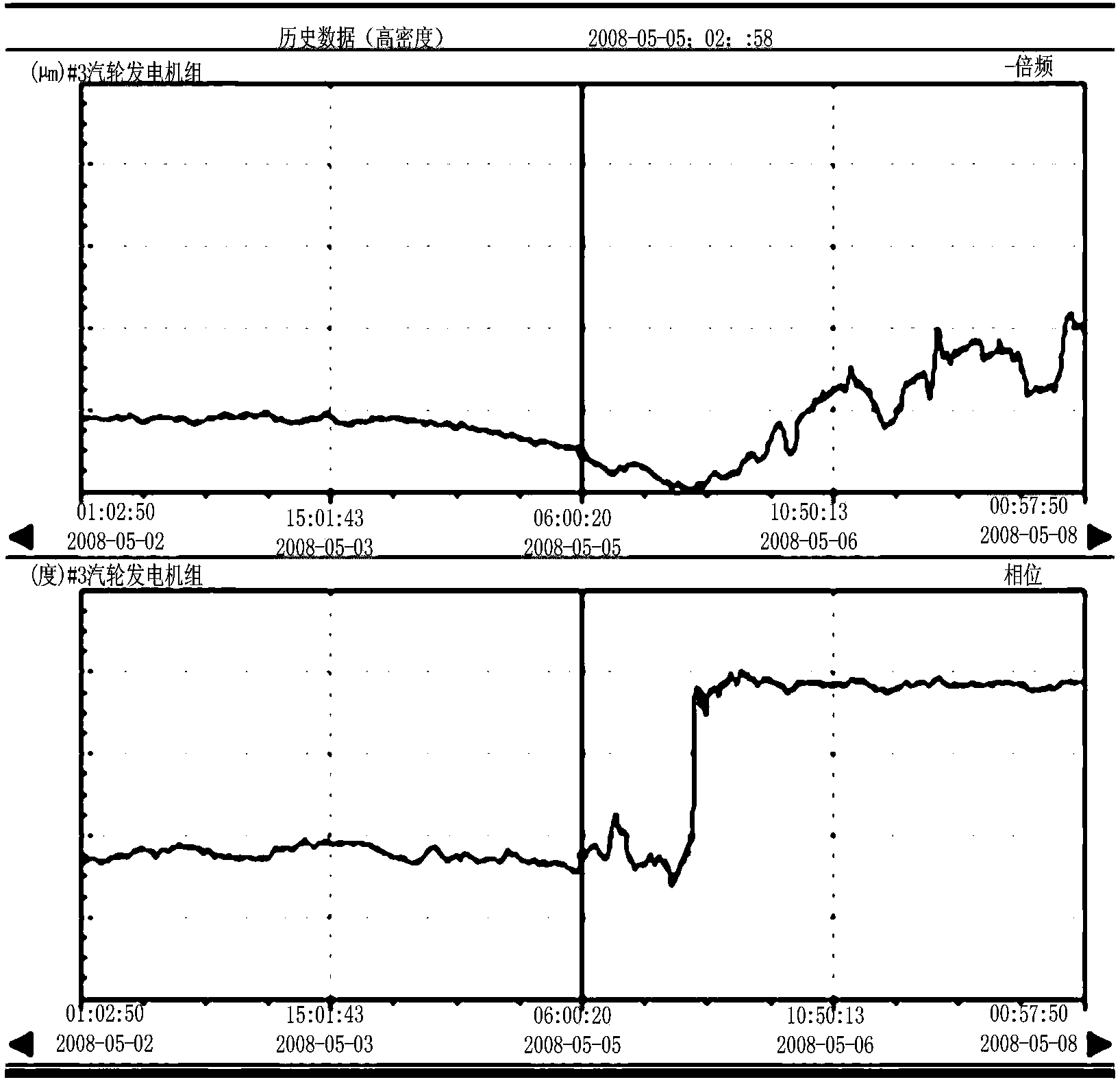

[0026] Since May 6, 2008 in a subcritical 600MW unit, the vibration of two bearings of the generator has climbed from the vibration trend. The vibration characteristics are as follows: (1) The vibration has nothing to do with the sealing oil temperature, hydrogen temperature and hydrogen pressure; (2) The vibration has nothing to do with the excitation current; (3) The vibration is related to the active load, the active load increases, the vibration increases, but even if the active load decreases, the vibration base continues to increase; (4) The vibration is mainly 1 times the frequency component ; (5) When the shaft vibration of No. 7 bearing and No. 8 bearing increases, the tile vibration also increases synchronously, but the shaft vibration and tile vibration of No. 6 bearing decrease; (6) When the vibration is at a high level, the controllable series compensation of the power grid exits During operation, the axial vibration of the No. 7 bearing in the X and Y directions d...

Embodiment 2

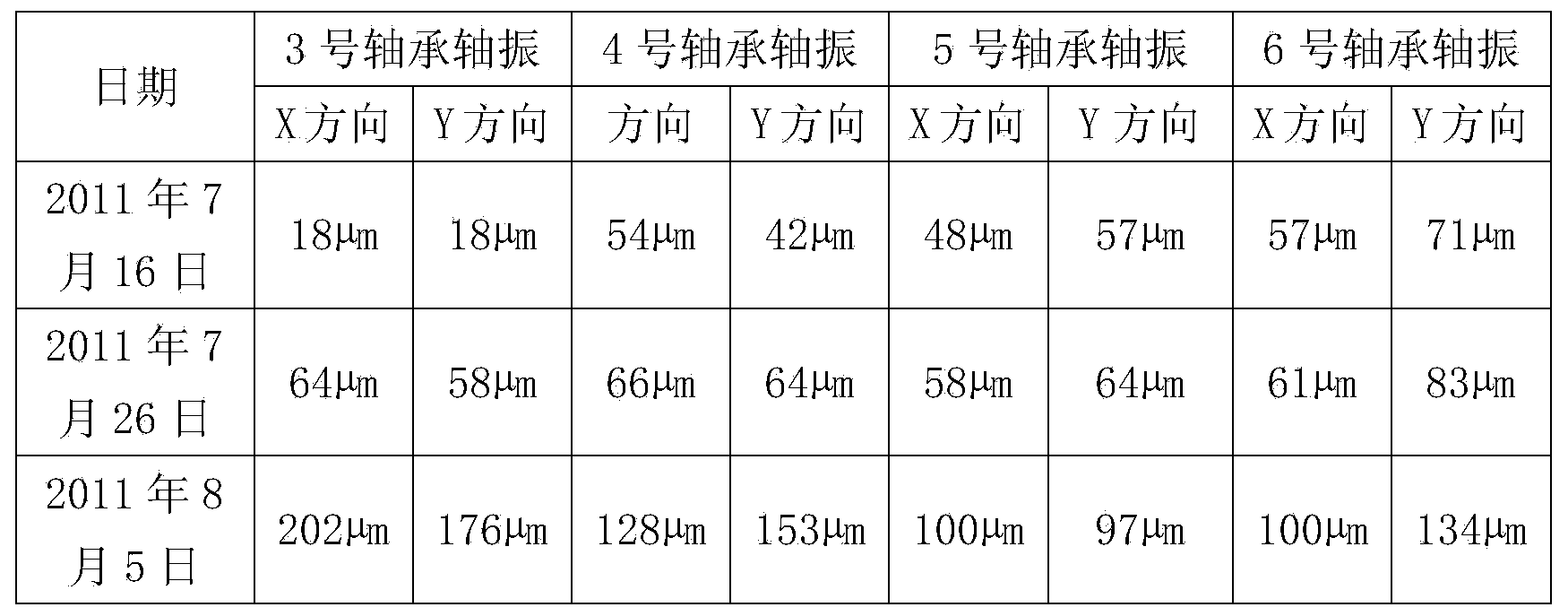

[0031] Referring to Table 1, the vibration of the two low-pressure rotors of a supercritical 660MW steam turbine has always been good. However, after July 18, 2011, it was found that the shaft vibration of the No. 3 bearing showed an increasing trend. Before the unit shut down on August 5, the maximum Shaft vibration has reached above 200μm.

[0032] Table 1

[0033]

[0034] The vibration of this unit is mainly in the 1-fold frequency component, and the vibration change is shown as a small increase in the shaft vibration of the No. The vibration exceeds 80μm, but when it passes near the low-pressure critical speed during shutdown, the shaft vibration of No. 3-6 bearings is very small, and the maximum does not exceed 75μm, and at low speed (about 300r / min) the journal of No. 3-6 bearings shakes The shaft vibration of the No. 3 bearing has a strong correlation with the steam seal system. When the desuperheating water is put in, the vibration will rise rapidly. In this case,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com