Cooling fan for diesel engine

A technology for cooling fans and diesel engines, which is applied to the components of pumping devices for elastic fluids, mechanical equipment, machines/engines, etc., can solve the problem of high fan noise, improve cooling components, avoid resonance, and reduce pressure shocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

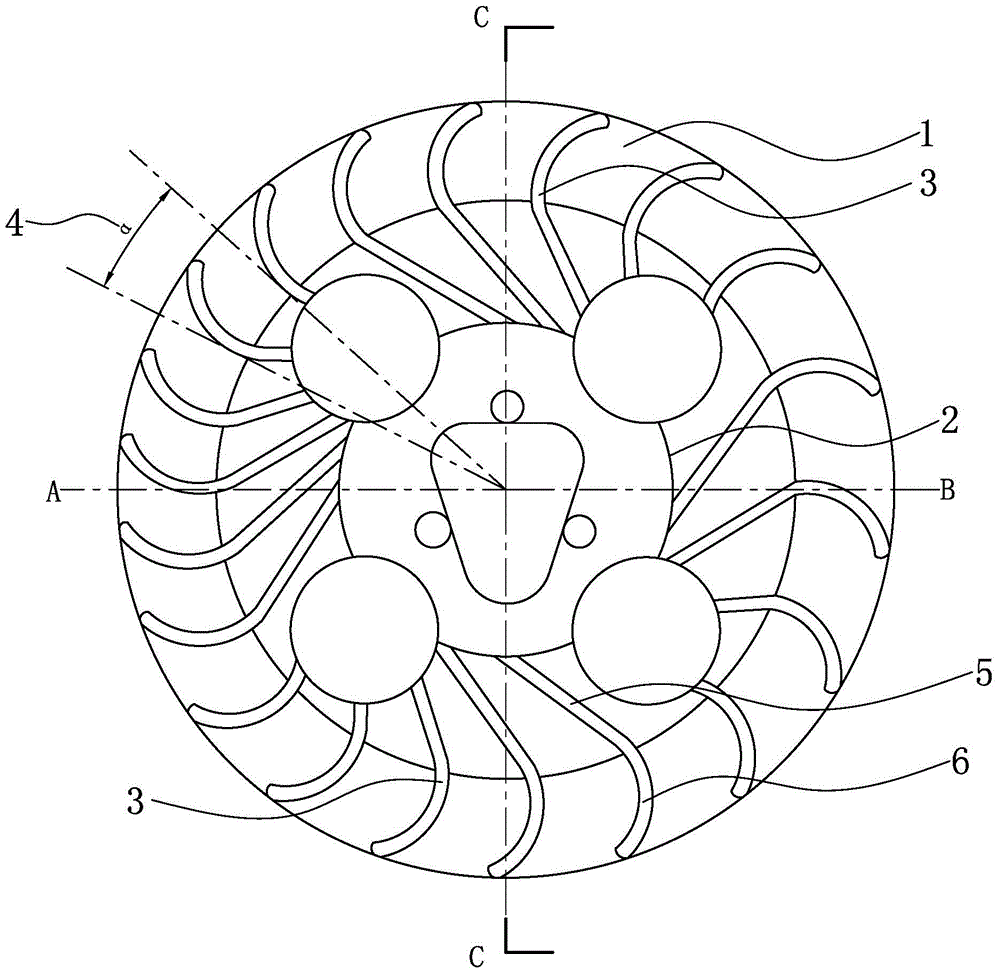

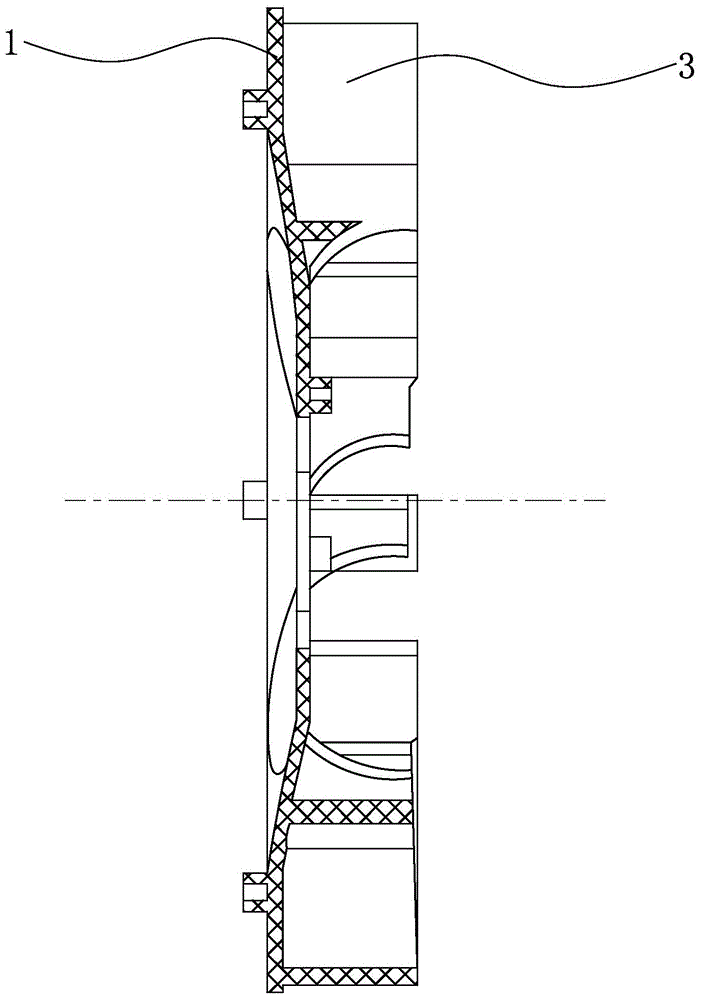

[0020] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 —3:

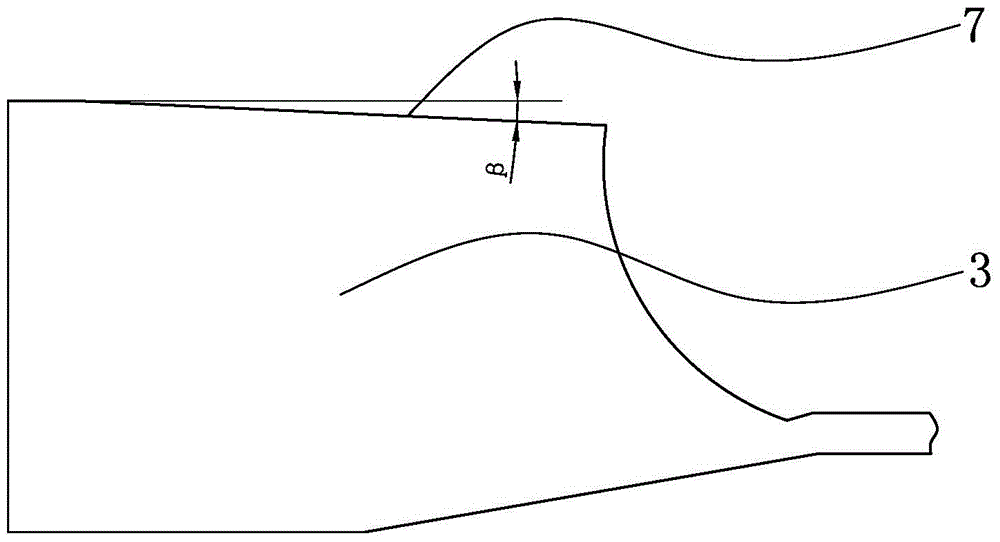

[0021] A cooling fan for a diesel engine, comprising a hub 1, characterized in that: a number of blades 3 are distributed in the outer circumferential direction of the central circle 2 on the hub surface, and the gap between two adjacent blades on the front semicircle in the clockwise direction The angle 4 increases gradually, and the included angle 4 between two adjacent blades on the rear semicircle gradually decreases. The blades include an inclined root 5 , and an arc 6 is provided at the outer end of the root.

[0022] The radius of the circle where the arc portion 6 of the blade is located is 16.5-18.5 mm.

[0023] The angle between the arc portions 6 of the two adjacent blades is 13.5° to 22.5°

[0024] There are four groups of blades 3, and the blade root of each group is directed toward a circle on the same radius that i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com