A coalbed methane well upper and lower three-dimensional combined extraction method

A coalbed methane well and three-dimensional technology, applied in mining equipment, earthwork drilling, gas discharge, etc., can solve the problems of limited effective pressure relief area, difficulty in achieving multi-purpose wells, and difficult maintenance of wellbore stability, so as to improve underground drainage efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

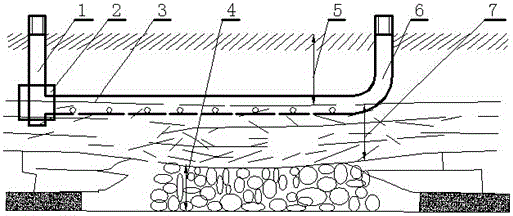

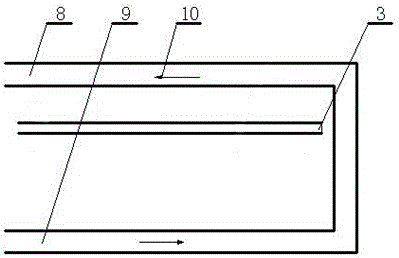

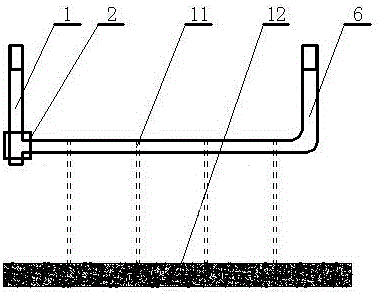

[0027] In the figure, the coalbed methane well upper and lower three-dimensional joint extraction method includes vertical well 1, horizontal well and vertical well joint 2, horizontal well section 3, caving zone 4, curved subsidence zone 5, and horizontal well 6 , fissure zone 7, air return lane 8, air inlet lane 9, partition 11, coal seam 12, sealing device 14, underground extraction borehole 15, goaf 16, vertical well 1 constructed on the ground and mining along the coal seam The horizontal well 6 in the horizontal direction, the bottom of the vertical well 1 shaft and the horizontal section 3 of the horizontal well are all located in the transition zone between the fracture zone 7 and the curved subsidence zone 5. The diameter of the bottom of well 1 is expanded to reduce the difficulty of connecting horizontal well 6 and vertical well 1. The diameters of the extraction pipes of vertical well 1 and horizontal well 6 are both larger than 200 mm. The length of the roof is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com