Cascade recovery device for waste power lithium batteries

A cascade recycling, lithium battery technology, applied in the direction of packaging, transportation and packaging, locking equipment, etc., can solve the problem of batteries that cannot be sorted, and achieve the effect of convenient recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

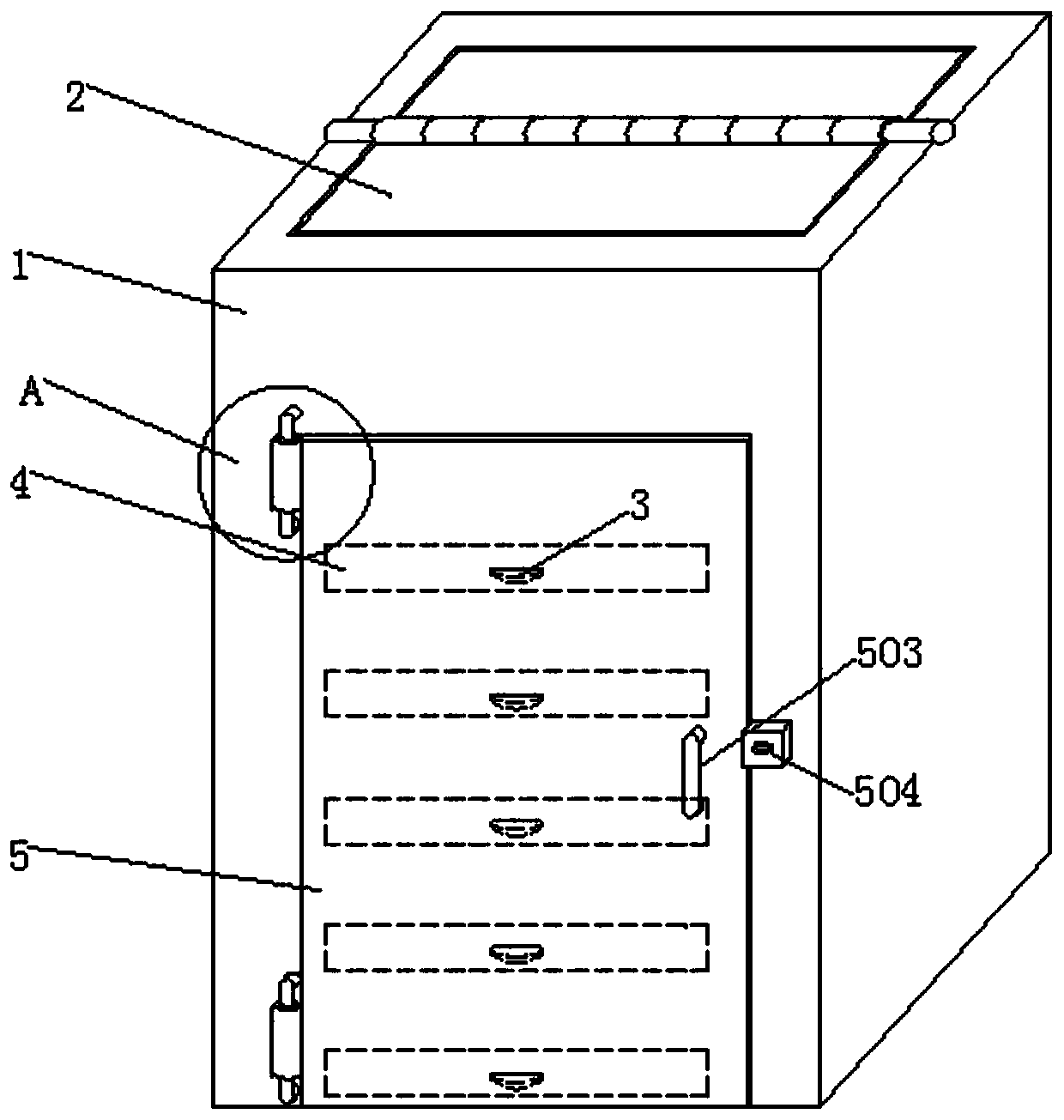

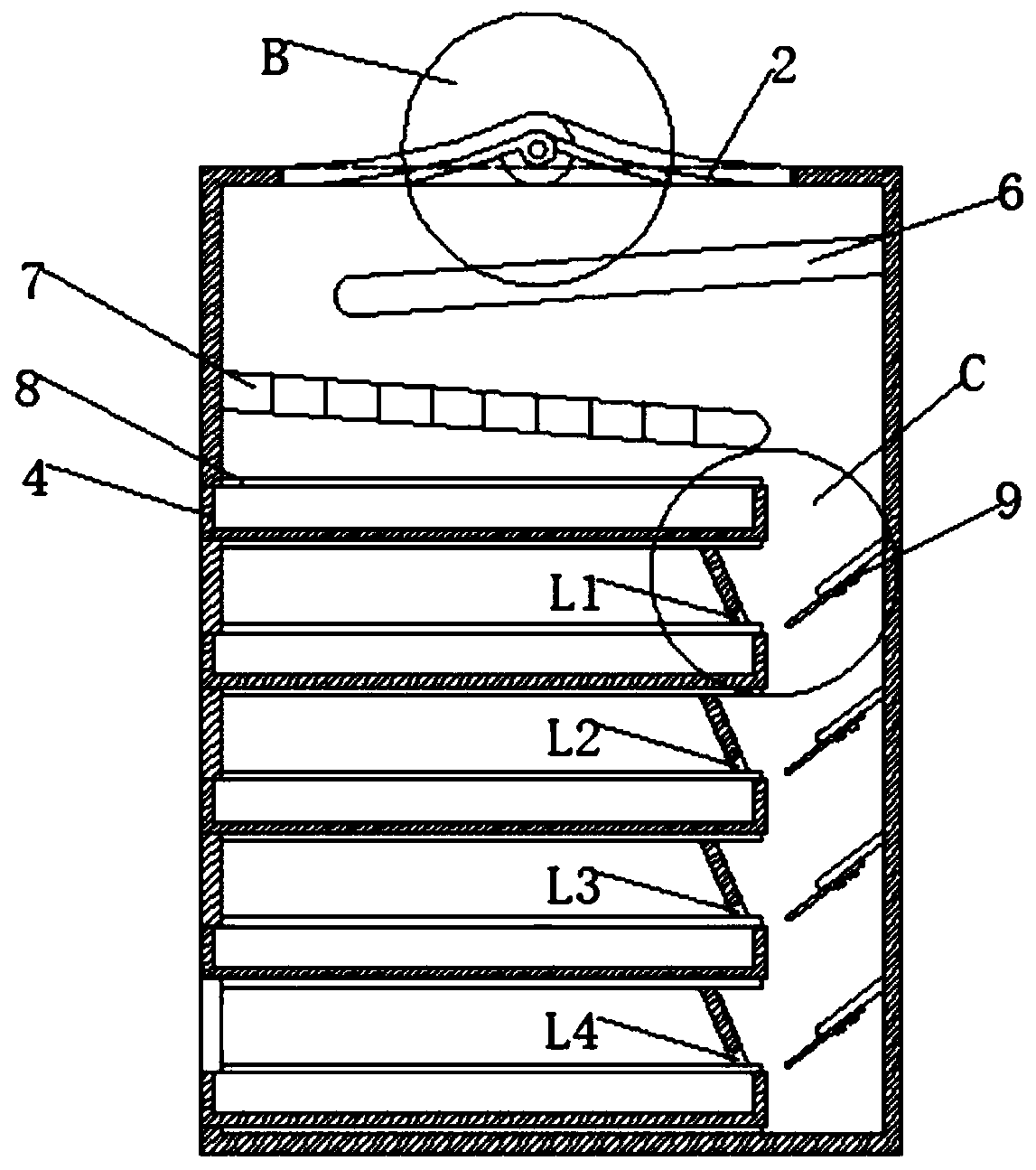

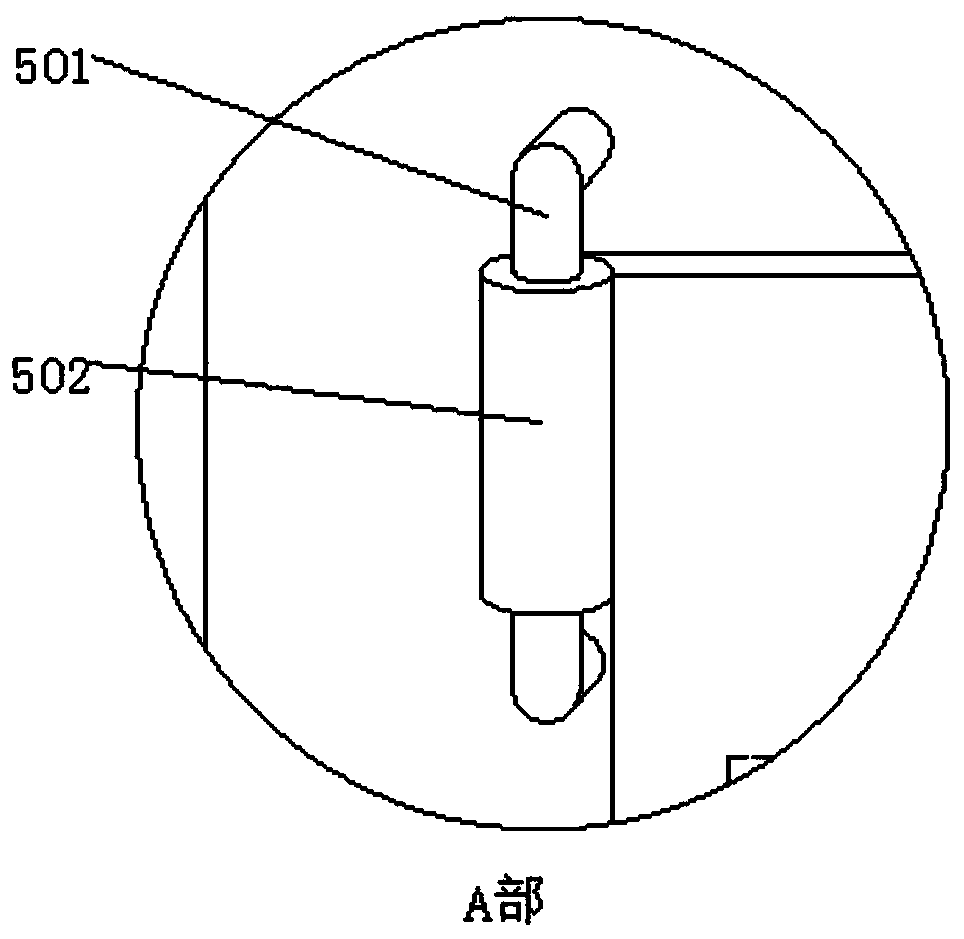

[0029] Such as Figure 1-5 As shown, a cascade recovery device for waste power lithium batteries includes a recovery box 1 and a storage box 4 placed inside the recovery box 1. A pressure-sensitive door 2 is provided on the top of the recovery box 1, and a pressure-sensitive door 2 is located at the bottom of the recovery box 1. The sliding plate 6 installed obliquely, the bottom of the sliding plate 6 is provided with a screening plate 7 opposite to the inclination direction of the sliding plate 6, the bottom of the screening plate 7 is provided with a storage box 4, and there are at least five storage boxes 4, and the storage box 4 There are guide rails 8 on both sides, and the guide rails 8 are tightly fixed to the inner wall of the recycling box 1. The storage box 4 is slidably embedded in the guide rail 8, and the side between the adjacent storage boxes 4 is provided with a lithium battery to distinguish There are at least four buckets 9 for the lithium battery area, and ...

Embodiment 2

[0031] Such as Figure 1-5 As shown, a cascade recovery device for waste power lithium batteries includes a recovery box 1 and a storage box 4 placed inside the recovery box 1. A pressure-sensitive door 2 is provided on the top of the recovery box 1, and a pressure-sensitive door 2 is located at the bottom of the recovery box 1. The sliding plate 6 installed obliquely, the bottom of the sliding plate 6 is provided with a screening plate 7 opposite to the inclination direction of the sliding plate 6, the bottom of the screening plate 7 is provided with a storage box 4, and there are at least five storage boxes 4, and the storage box 4 There are guide rails 8 on both sides, and the guide rails 8 are tightly fixed to the inner wall of the recycling box 1. The storage box 4 is slidably embedded in the guide rail 8, and the side between the adjacent storage boxes 4 is provided with a lithium battery to distinguish There are at least four buckets 9 for the lithium battery area, and ...

Embodiment 3

[0034] Such as Figure 1-5As shown, a cascade recovery device for waste power lithium batteries includes a recovery box 1 and a storage box 4 placed inside the recovery box 1. A pressure-sensitive door 2 is provided on the top of the recovery box 1, and a pressure-sensitive door 2 is located at the bottom of the recovery box 1. The sliding plate 6 installed obliquely, the bottom of the sliding plate 6 is provided with a screening plate 7 opposite to the inclination direction of the sliding plate 6, the bottom of the screening plate 7 is provided with a storage box 4, and there are at least five storage boxes 4, and the storage box 4 There are guide rails 8 on both sides, and the guide rails 8 are tightly fixed to the inner wall of the recycling box 1. The storage box 4 is slidably embedded in the guide rail 8, and the side between the adjacent storage boxes 4 is provided with a lithium battery to distinguish There are at least four buckets 9 for the lithium battery area, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com