Multi-level cross-mining-area ground drilling well pattern laying method

A technology for ground drilling and horizontal wells, which is used in mining equipment, wellbore/well components, and production fluids to improve extraction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

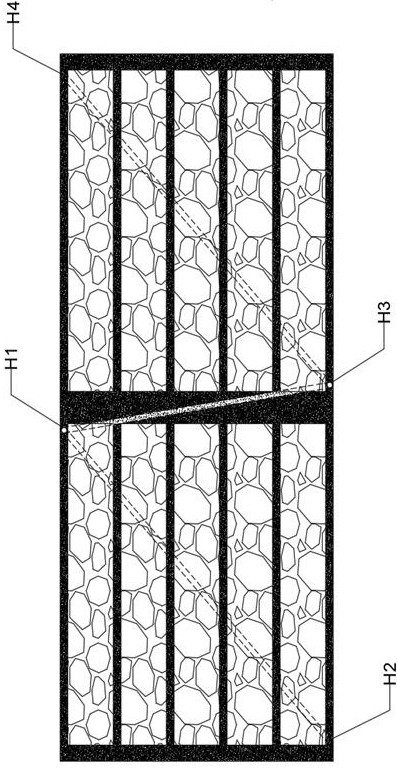

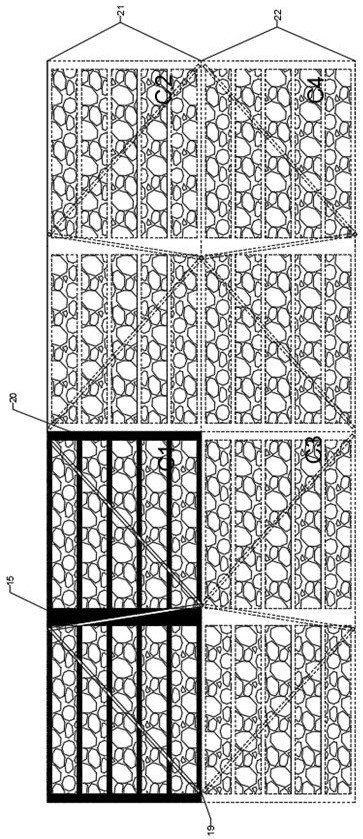

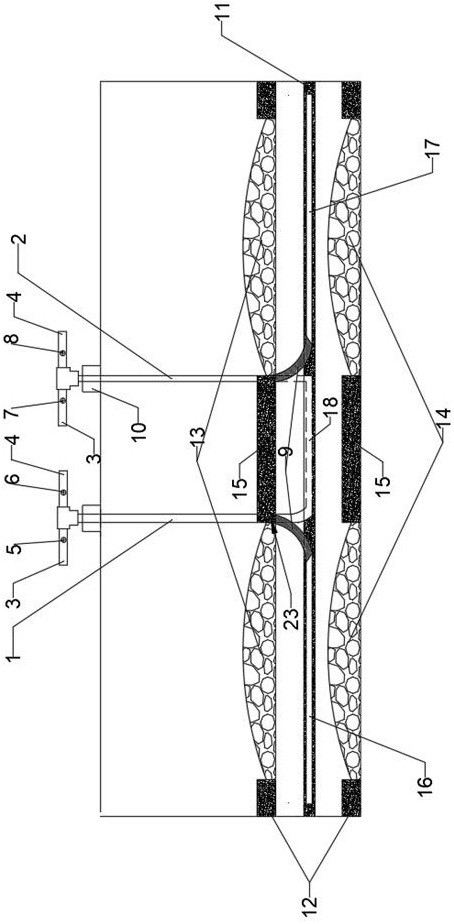

[0031] combine Figure 1~4 , illustrate the specific implementation process of the present invention's multi-horizontal cross-production area surface drilling well pattern layout method, comprising the following steps:

[0032] (1) According to the coal mine geological exploration data, the mine field is divided into two stages according to a certain elevation in the parallel direction within the mine field, and then each stage is divided into two mining areas with independent production systems along the direction of each stage, From the first stage of mining area C 1 The junction H of coal pillar 15 on the upper mountain and coal pillar 12 on the boundary of the upper minefield in the mining area 1 A horizontal well 1 is drilled at the corresponding position above the ground, and the first horizontal section 16 of the horizontal well is drilled in the middle coal seam and extends to the coal pillar 19 in the middle of the first and second stages and the junction H of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com