Modified calcium carbonate with good elasticity and preparation method thereof

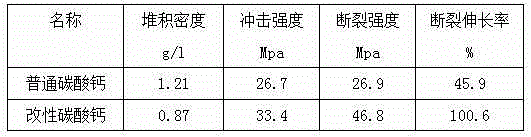

A calcium carbonate, modified technology, applied in chemical instruments and methods, inorganic pigment treatment, dyeing low molecular organic compound treatment, etc., can solve the problems of different interface properties, material mechanical properties decline, poor compatibility, etc., to achieve the preparation method Simple, easy to operate, good strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in detail below through specific examples.

[0015] A modified calcium carbonate with good elasticity is prepared from the following raw materials in parts by weight (kg): calcium carbonate 85, polyvinyl chloride 5.5, transparent ABS 5, synthetic rubber 4, carbide slag 2, coarse aggregate 1.5, polyvinyl chloride Tetrafluoroethylene 3, cationic starch 2, lignosulfonate 2, modified titanium dioxide 2.5;

[0016] The modified titanium dioxide is made of the following raw materials in parts by weight (kg): nanometer titanium dioxide 50, mica powder 2, crushed zeolite molecular sieve 4, ferrocene 5, mineral fiber 3, sodium pyrophosphate 2, pure acrylic emulsion 3, ring Butyl oxyoleate 3, phosphate ester 2, water 50; the preparation method is to first add pure acrylic emulsion, nano-titanium dioxide, mica powder, crushed zeolite molecular sieve, mineral fiber, and water to form a suspension, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com