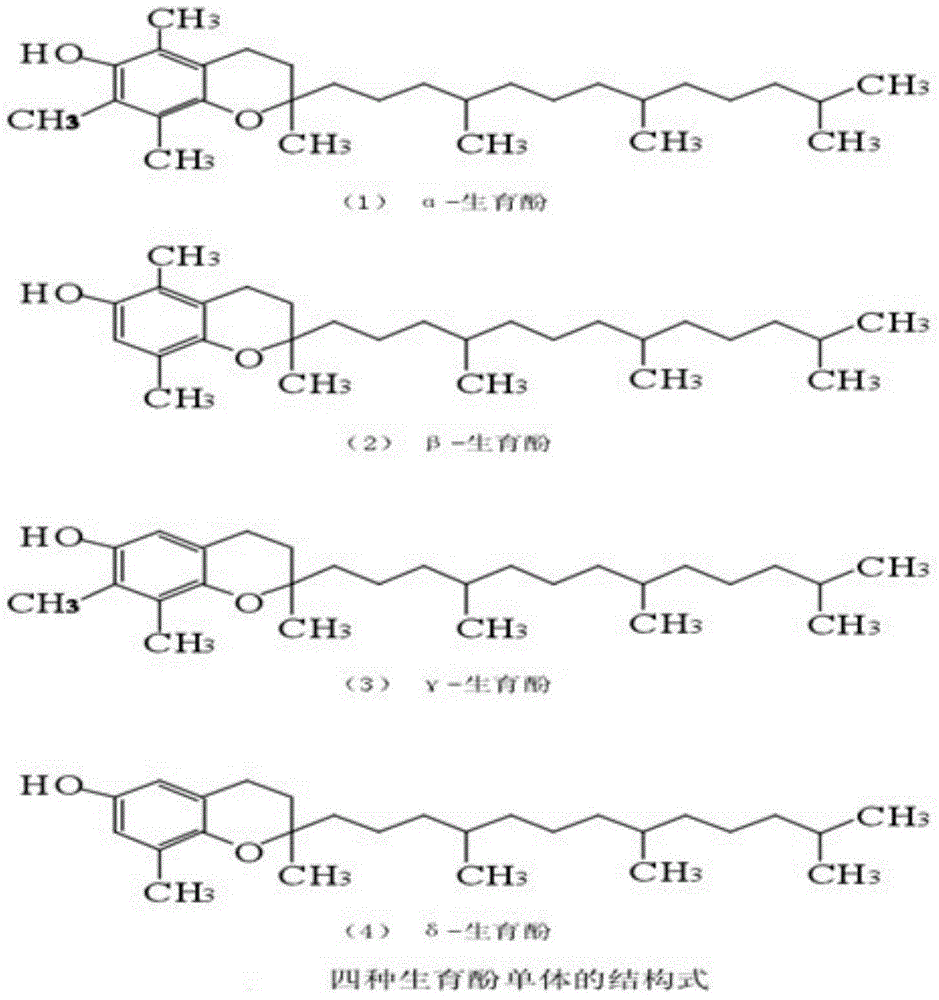

Method for preparing natural alpha tocopherol and mixing tocopherol by one-step method

A natural technology of tocopherol, which is applied in the direction of pharmaceutical formulations, cosmetic preparations, dressing preparations, etc., can solve problems such as high α-tocopherol content, affecting product quality, and affecting use effects, so as to achieve high product quality and eliminate Residue of toxic organic solvents and the effect of using less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The method for preparing natural α-tocopherol and mixed tocopherol by one-step method comprises the following steps:

[0040] (1) Methyl esterification: Preheat 1Kg of soybean oil deodorized distillate to 40°C, slowly add 700ml of methanol reagent, add 5% concentrated sulfuric acid dropwise to the reactant while stirring, and control the reaction temperature at 66-68°C. The time is 3h;

[0041] (2) Washing: Add 80-85°C hot water to the above reaction solution, wash until the pH value of the water phase is greater than 5.0, let stand and separate and discard the water phase;

[0042] (3) Dissolving and filtering: add 500ml of ethanol solution to the organic phase, stir, slowly cool down to 10°C, let stand for 2h, and suction filter through a Buchner funnel to obtain 1640ml of tocopherol solution;

[0043] (4) Adsorption:

[0044] (a) Fluidized bed adsorption of solution: 1# resin column is loaded with 200ml of strong basic anion exchange resin, and 600ml of 1mol / L sodi...

Embodiment 2

[0051] The method for preparing natural α-tocopherol and mixed tocopherol by one-step method comprises the following steps:

[0052] (1) Methyl esterification: preheat 1Kg of corn oil deodorized distillate to 40°C, slowly add 500ml of methanol reagent, add 2% concentrated sulfuric acid dropwise to the reactant while stirring, and control the reaction temperature at 60-64°C. The reaction time is 3h;

[0053] (2) Washing: Add 80-85°C hot water to the above reaction solution, wash until the pH value of the water phase is greater than 5.0, let stand and separate and discard the water phase;

[0054] (3) Dissolving and filtering: add 200ml of ethanol solution to the organic phase, stir, slowly cool down to 5°C, let stand for 2h, and suction filter with Buchner funnel to obtain 1240ml of tocopherol solution;

[0055] (4) Adsorption:

[0056] (a) Fluidized bed adsorption of solution: 1# resin column is loaded with 250ml of strong basic anion exchange resin, and 750ml of 1mol / L sodi...

Embodiment 3

[0063] The method for preparing natural α-tocopherol and mixed tocopherol by one-step method comprises the following steps:

[0064] (1) methyl esterification: get rapeseed oil deodorization distillate 700g, olive oil deodorization distillate 300g and preheat to 35 ℃, slowly add 1000ml methanol reagent, add dropwise 6% concentrated sulfuric acid in the reactant under the stirring situation, The reaction temperature is controlled at 68-70°C, and the reaction time is 2h;

[0065] (2) Washing: Add 80-85°C hot water to the above reaction solution, wash until the pH value of the water phase is greater than 5.0, let stand and separate and discard the water phase;

[0066] (3) Dissolution and filtration: add 1000ml of ethanol solution to the organic phase, stir, slowly cool down to 25°C, let stand for 2h, and filter through Buchner funnel to obtain 2404ml of tocopherol solution;

[0067] (4) Adsorption:

[0068] (a) Fluidized bed adsorption of solution: 1# resin column is loaded wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com