Waste incineration fly ash resource method based on magnesium potassium phosphate adhesive

A technology of potassium magnesium phosphate adhesive and waste incineration fly ash, which is applied in the field of resource utilization of hazardous waste, can solve the problems of late strength shrinkage, fast condensation, and large concentrated release of hydration heat, etc., and achieve low leaching concentration and overcoming strength The effect of retraction and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

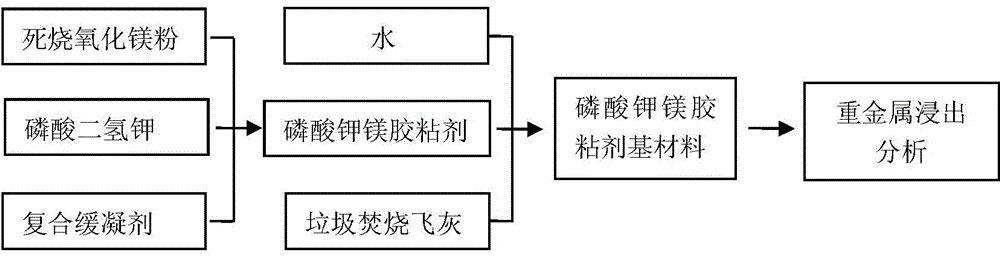

Method used

Image

Examples

Embodiment 1

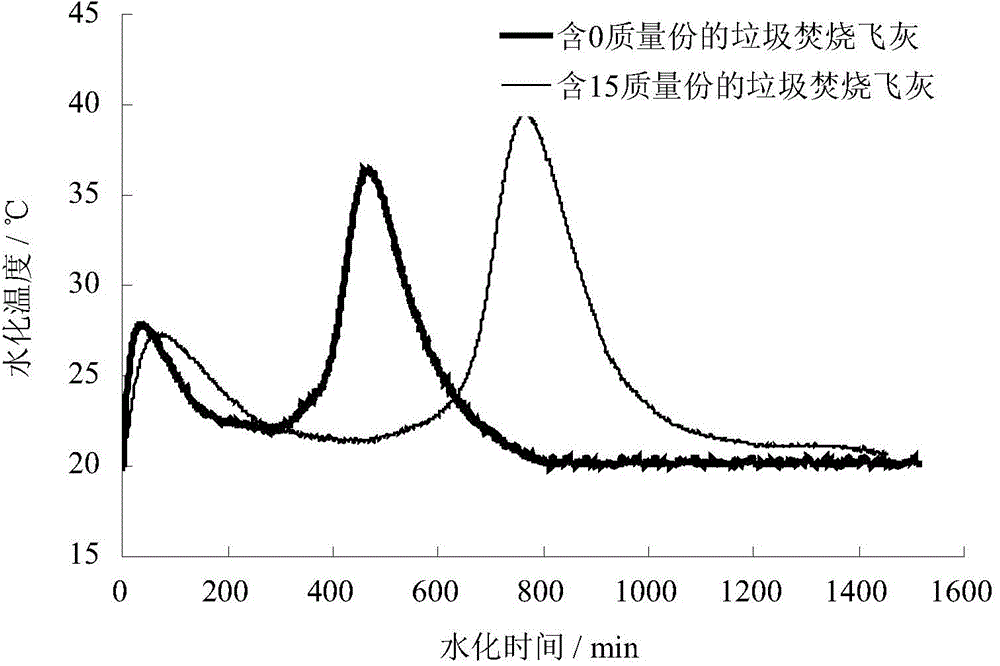

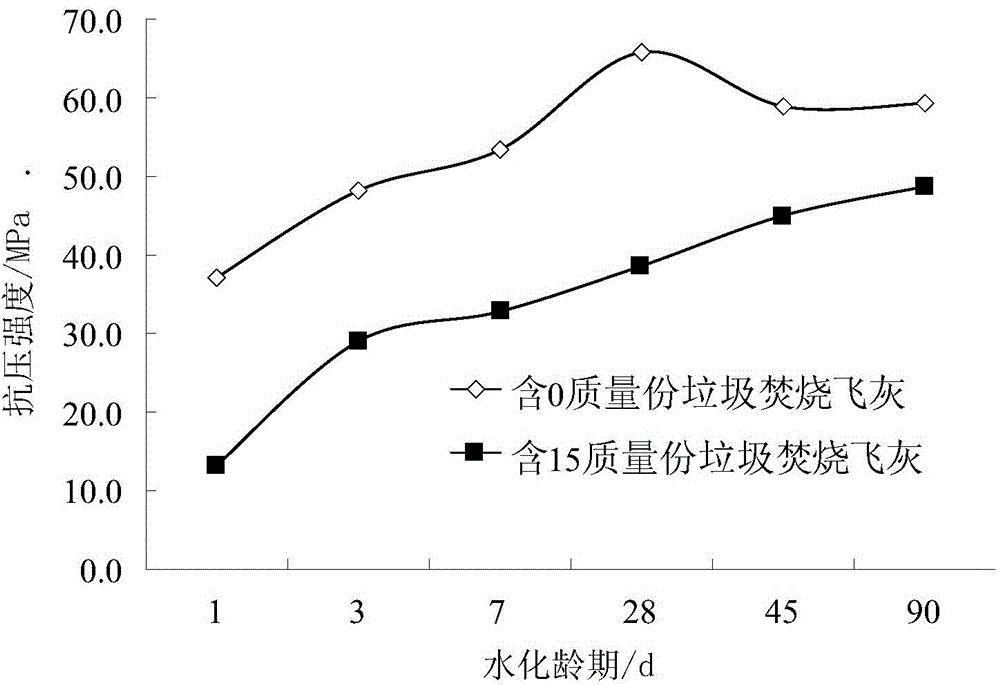

[0035] Get the dead burnt magnesium oxide powder (wherein MgO, CaO and SiO 2 The mass fractions are 96.8%, 1.33% and 0.92%, respectively, and the specific surface area is 216m 2 kg -1 , the same below) and 28 parts by mass of potassium dihydrogen phosphate (the main particle size is 40 / 350~60 / 245 (mesh / μm), the same below), and 8 parts by mass of composite retarder (sodium tetraborate: ten Disodium hydrogen phosphate dihydrate:ammonium chloride=2:3:6, mass ratio) to prepare MKPC with a coagulation time of 65min. Get 15 mass parts (do contrast with 0 mass part simultaneously) the rubbish incineration fly ash (specific surface area is 450m 2 kg -1 , the same below) (admixed with a certain amount of lead nitrate and cadmium nitrate) and 85 parts by mass of the above-mentioned MKPC, externally mixed with 16 parts by mass of water. Use the NJ-160A cement slurry mixer to stir slowly for about 2 minutes to mix the components evenly, and then stir rapidly for 3 to 4 minutes to obt...

Embodiment 2

[0046] Take 30 parts by mass of waste incineration fly ash and 85 parts by mass of MKPC prepared in Example 1, and add 16 parts by mass of water. Use the NJ-160A cement slurry mixer to stir slowly for about 2 minutes to mix the components evenly, and then stir rapidly for 3 to 4 minutes to obtain the MKPC-based material slurry (the content of Pb in the slurry is about 12000mg / kg, and the content of Cd is about 3000mg / kg). Test the heavy metal leaching of MKPC-based material slurry hydration (temperature 10-30°C, ambient humidity 20-70%) for a certain period of time, the results are as follows Figure 5 shown. The leaching concentrations of heavy metals Pb and Cd in the MKPC-based material slurry after 7 days of hydration have been lower than the requirements of the "Hazardous Waste Identification Standard" (GB5085.3-2007) (dissolution rate of Pb≤5mg / L, dissolution rate of Cd≤ 1mg / L). With the prolongation of the hydration age, the leaching concentration of Pb in the MKPC-b...

Embodiment 3

[0048] Different mass parts of waste incineration fly ash and 85 mass parts of MKPC prepared in Example 1 were taken, and 16 mass parts of water were added. Use the NJ-160A cement slurry mixer to stir slowly for about 2 minutes to mix the components evenly, and then stir rapidly for 3 to 4 minutes to obtain the MKPC-based material slurry (the content of Pb in the slurry is about 12000mg / kg, and the content of Cd is about 3000mg / kg). Test the leaching of heavy metals when the MKPC-based material slurry is hydrated for 90 days, the results are as follows Figure 6 shown. The leaching concentrations of Pb and Cd in the MKPC-based hardened body gradually increased with the increase of the mass fraction of incineration fly ash. When the mass fraction of incineration fly ash reaches 37.5, the leaching concentration of Pb and Cd in the MKPC-based hardened body is still lower than the requirements of the "Hazardous Waste Identification Standard" (GB5085.3-2007) (the leaching concen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com