Making method of blank mould

A production method and master mold technology, applied in glass pressing, manufacturing tools, glass molding, etc., can solve problems such as uneven thickness of the bottle body, potential safety hazards, sticking wires in the bottle, etc., to improve the quality of glass bottles, The effect of improving production quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

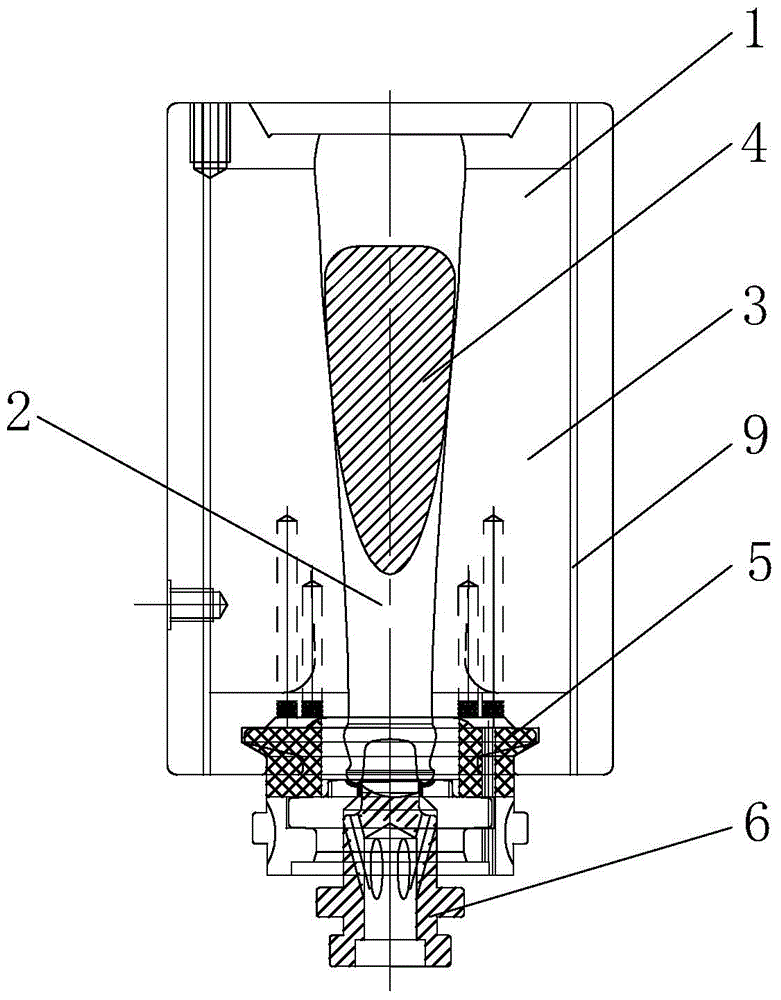

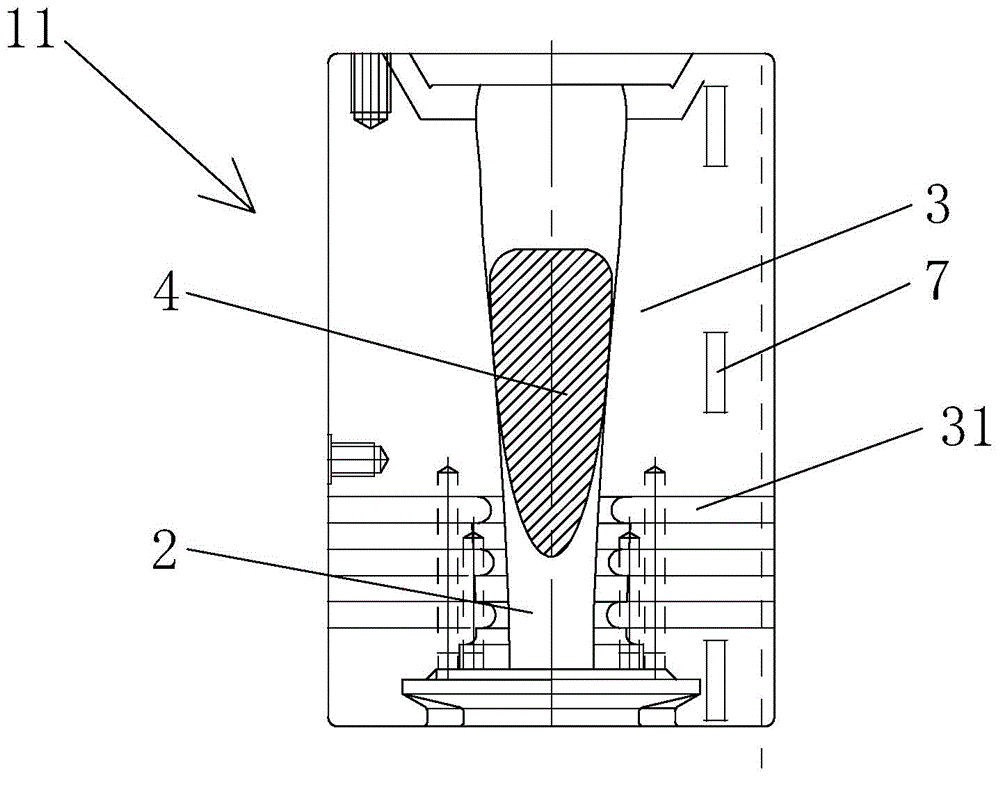

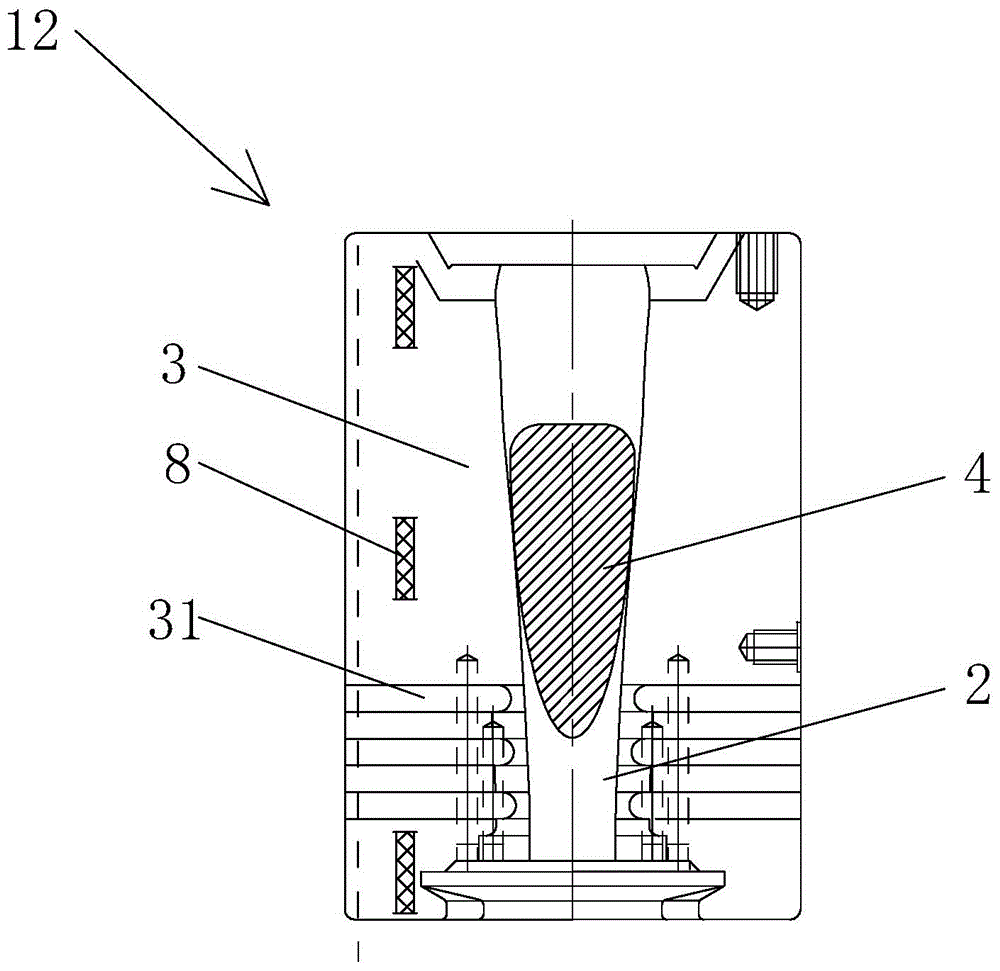

[0021] Example: A method of making a prototype, such as Figure 2-4 As shown, it includes the following steps:

[0022] In the first step, a cavity 2 that penetrates up and down is processed on the flat portion 10 of the male mold 11 and the female mold 12. The processing method is a milling process. The two cavities 2 cooperate with each other to form a cavity 2 inside the first mold 1 A bottle cavity, at this time the flat part 10 where the male mold 11 and the female mold 12 are closely attached is the seam surface 3;

[0023] The second step is to mill several vent grooves 31 on the seam surface 3, and mill the vent groove 31 to be 0.15mm below the plane part 10. The several vent grooves 31 are used to connect the inside of the bottle cavity with the outside air. And the exhaust groove 31 is provided in the lower half of the seam surface 3;

[0024] In the third step, a plurality of triangular ribs 7 and grooves 8 matched with the triangular ribs 7 are provided on the joint sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com