Settlement method of vanadium mud in leached vanadium liquid

A vanadium liquid and leaching technology, which is applied in the field of vanadium mud leaching in vanadium liquid, can solve the problems that the production system cannot be shut down normally, it is difficult to obtain clarified vanadium liquid, and the sedimentation speed of vanadium mud is slow, so as to improve the separation efficiency of vanadium mud , Shorten the vanadium precipitation time, improve the effect of purification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

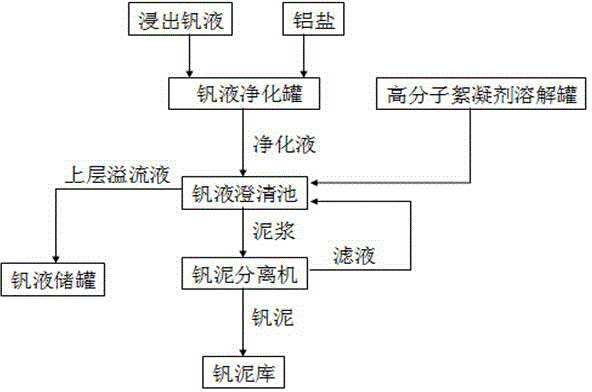

[0018] Example 1: figure 1 As shown, the processing steps of the sedimentation method of vanadium mud in this vanadium leaching liquid are as follows.

[0019] The 200.00m 3 The vanadium leaching solution is introduced into the purification reactor, and 300.00kg of polyaluminum chloride is added to the vanadium leaching solution for purification operation. After the purification process is over, pour the purified vanadium liquid and cationic polyacrylamide solution into the vanadium liquid settling tank for sedimentation; the concentration of cationic polyacrylamide is 3.00‰ (mass), and the dosage is 40.00m 3 . In the settling tank, the vanadium mud sinks rapidly, and the impurity silicon content after clarification of the vanadium liquid is 75.00 mg / L, and the phosphorus content is 4.00 mg / L; In the vanadium process, the vanadium is deposited, and the bottom mud is separated from the solid and liquid by the vanadium mud separation equipment. The vanadium precipitation tim...

Embodiment 2

[0020] Embodiment 2: The processing steps of the settling method of vanadium mud in this vanadium leaching liquid are as follows.

[0021] In the 200.00m 3 Add 500.00kg of aluminum sulfate to the vanadium solution, and add 80.00m of amphoteric polyacrylamide with a concentration of 0.50‰ (mass) to the purified solution after purification 3 , The vanadium mud sinks rapidly, the vanadium liquid is clarified, the impurity silicon content in the vanadium liquid is 105.00mg / L, and the phosphorus content is 11.00mg / L. Use this clarified vanadium solution to precipitate vanadium, the time for vanadium precipitation is 110 minutes, the supernatant concentration of the vanadium precipitation is 0.11g / L, and the ammonium vanadate obtained is calcined to obtain powder vanadium pentoxide, the composition is: V 2 o 5 99.01%, Si 0.069%, Fe 0.057%, P 0.011%, K 2 O+Na 2 O 0.58%, C 0.049%, S 0.066%, meet the requirements of the standard YB / T5304-2011.

Embodiment 3

[0022] Embodiment 3: The processing steps of the sedimentation method of vanadium mud in this vanadium leaching liquid are as follows.

[0023] In the 200.00m 3 Add 800.00kg of aluminum chloride and 800.00kg of polyaluminum sulfate to the vanadium solution, and add 60.00m of anionic polyacrylamide with a concentration of 5.00‰ (mass) to the purified solution after purification 3 , The vanadium mud sinks rapidly, the vanadium liquid is clarified, the impurity silicon content in the vanadium liquid is 98.00mg / L, and the phosphorus content is 9.00mg / L. Use this clarified vanadium solution to precipitate vanadium, the concentration of the vanadium supernatant is 0.095g / L, and the vanadium precipitation time is 102 minutes, and the ammonium vanadate obtained is calcined to obtain powder vanadium pentoxide, the composition is: V 2 o 5 98.98%, Si 0.053%, Fe 0.068%, P 0.007%, K 2 O+Na 2 O 0.64%, C 0.038%, S 0.086%, meet the requirements of the standard YB / T5304-2011.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com