Plasma synergistic ultrasonic cavitation effect waste water treatment reactor

A technology of cavitation effect and wastewater treatment, applied in the directions of oxidized water/sewage treatment, electrochemical water/sewage treatment, illuminated water/sewage treatment, etc., to achieve the effects of uniform air distribution, high efficiency and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

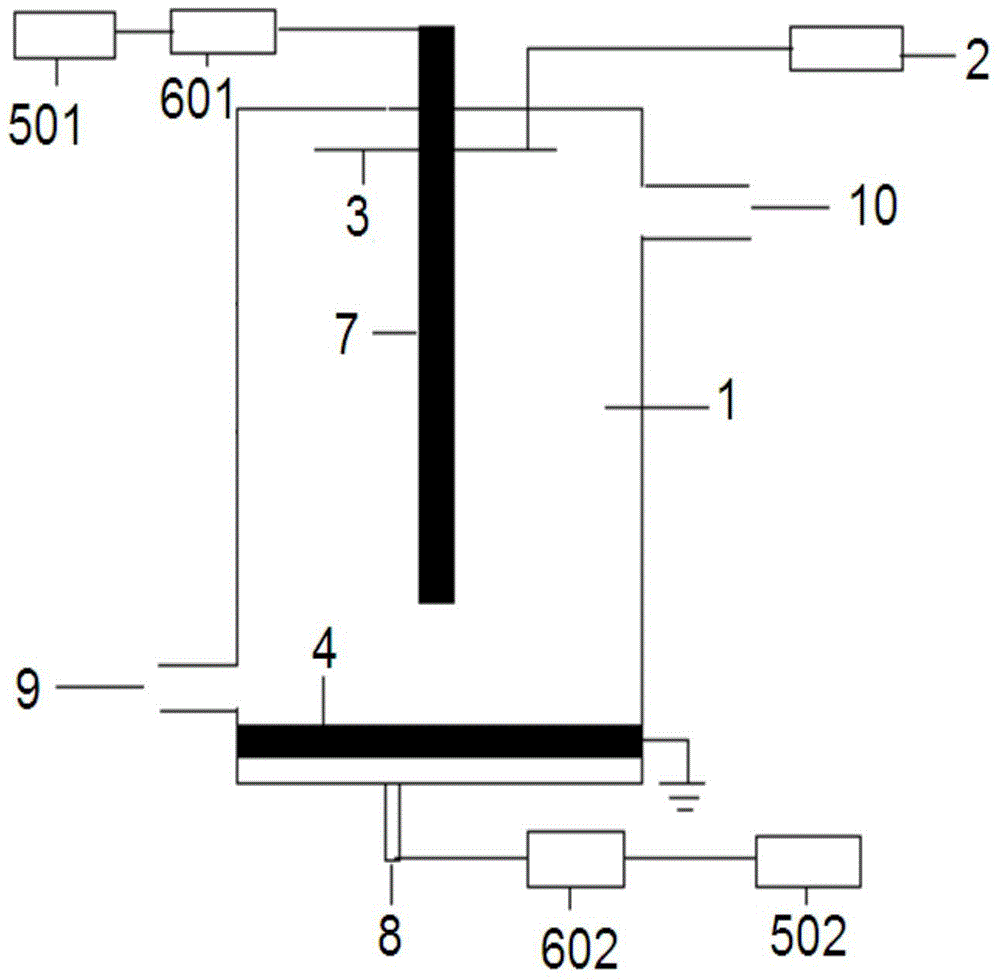

[0020] Such as figure 1 As shown, the plasma-assisted ultrasonic cavitation effect wastewater treatment reactor of the present invention includes a line-plate gas-liquid two-phase discharge reactor 1, a high-voltage pulse power supply 2, a wire electrode 3, a plate electrode 4, and a horn immersed ultrasonic generator 501 , a cleaning tank type ultrasonic generator 502 , a first piezoelectric transducer 601 and a second piezoelectric transducer 602 . The line-plate gas-liquid two-phase discharge reactor 1 is cylindrical, and its diameter and height are integral multiples of λ / 2, where λ is the wavelength of ultrasonic waves. The line-plate type gas-liquid two-phase discharge reactor 1 is placed vertically, with a water inlet 9 and a water outlet 10, the water inlet 9 is at the bottom of the reactor 1, and is located above the plate electrode 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com