Process for preparing zinc sulfate

A technology of zinc sulfate and zinc sulfate solution, applied in directions such as zinc sulfate, can solve the problems of low purity of zinc sulfate, low production efficiency, complicated steps, etc., and achieve the effects of easy manual control, easy operation, and concise process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

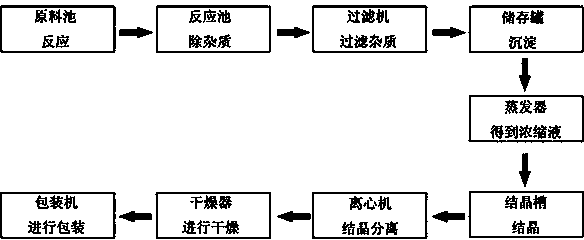

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail;

[0010] Such as figure 1 Shown, a kind of technology of preparing zinc sulfate, its technology is: the sub-zinc oxide, zinc oxide in the waste slag that produces zinc is placed in raw material pool, inject dilute sulfuric acid in raw material pool, make it react to generate zinc sulfate solution, and then import the zinc sulfate solution into the reaction pool, remove iron, cobalt, copper and other impurities in the zinc sulfate solution in the reaction pool, filter out the impurities through a filter, and import the zinc sulfate solution that has completely removed the impurities into the storage tank Precipitation treatment in the middle, and preheating treatment, preheating to 75 ° -90 °, the preheated zinc sulfate solution is sent to the evaporator for evaporation to obtain a concentrated solution, the concentrated liquid is placed in the cry...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com