Spindle vertical-horizontal turnover device

A turning device and spindle technology, applied in the direction of manufacturing tools, wood processing equipment, slotting machines, etc., to achieve the effects of high positioning accuracy, fast response, and flexible turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

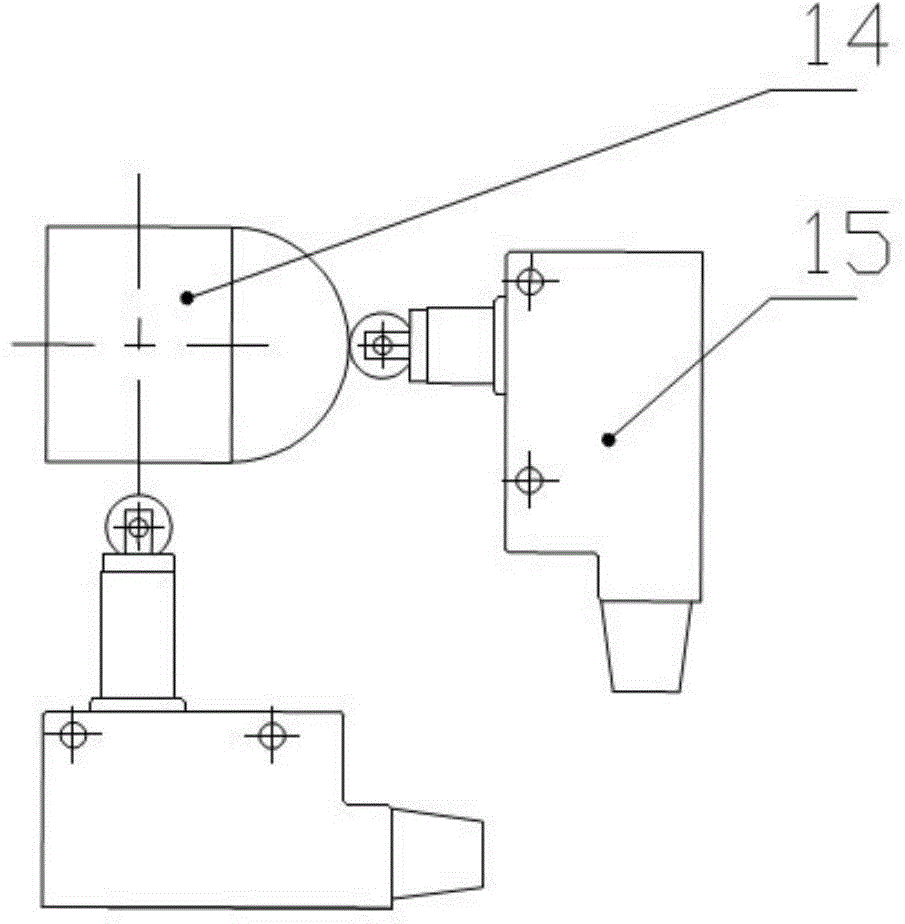

[0021] Such as Figure 1-3.2 As shown, a main shaft vertical and horizontal turning device, the device includes the main shaft shaft seat A1, the left main shaft swing bearing seat 2, the fixed plate of the reducer 3, the reducer 4, the driving motor 5, the turning support assembly 6, the locking cylinder 7, Locating pin 8, overturn drive shaft 9, electric main shaft 10, sliding plate 11, main shaft seat B12, right main shaft swing bearing seat 13, bumper 14, limit switch 15, lead 16.

[0022] The sliding plate 11 is connected with the left main shaft swing bearing seat 2 and the right main shaft swing bearing seat 13 through screws, the drive motor 5 is connected with the reducer 4, the reducer motor 2 is connected with the turning transmission shaft 9 through a coupling, and the turning drive The shaft 9 is connected to the main shaft seat A1 by screws, the electric spindle 10 is installed and tightly held between the main shaft seat A1 and the main shaft seat B12, and the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com