Axial pressure type rust removing device for surface of petroleum drill rod

A technology of oil drill pipe and axial pressure, which is applied in the direction of grinding drive device, grinding workpiece support, grinding machine, etc., can solve the problems of high operating intensity, long construction period, and low efficiency of construction personnel, and achieve the goal of reducing labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

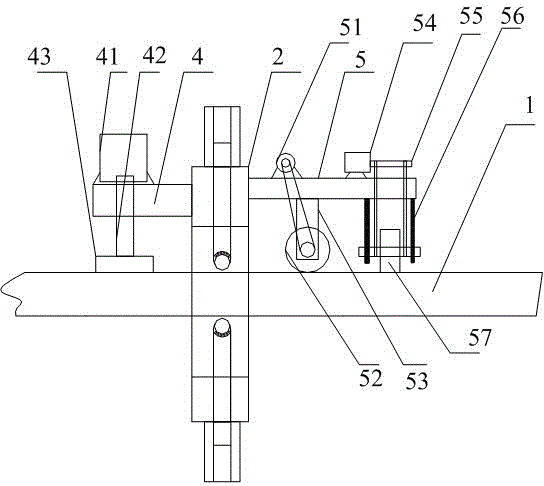

[0022] Such as Figure 1-Figure 3 shown

[0023] Axial pressure oil drill pipe surface derusting device, including an annular rotating plate 2 sleeved on the outer diameter of the oil drilling pipe 1, there is a gap between the inner diameter surface of the annular rotating plate 2 and the oil drilling pipe 1, and the outer surface of the annular rotating plate A plurality of sleeves 3 are provided, the two ends of the sleeves are open, and a sliding column 32 passing through the annular rotating plate is also included. One end of the sliding column 32 extends to the sleeve inner cavity 31 inside the sleeve 3, and the sleeve 3 and the sliding column 32 for threaded socketing, the end of the sliding column 32 extending to the inside of the sleeve 3 is the knob end, and the end surface of the knob end is provided with a bar groove 34; the other end of the sliding column 32 is connected with a universal ball 33, and the universal ball 33 is crimped To the outer diameter surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com