Reducing impact insertion-cutting type annular banana comb cutting device

A drop-comb and ring-shaped technology is applied in the field of variable-diameter impact plunge-cut annular banana drop-comb devices, which can solve the problems of not being able to comb the whole bunch of bananas one by one, increasing the incidence of microbial diseases, and high processing costs of banana products. To achieve the effect of good combing effect, improve the quality of the incision, and improve the overall aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

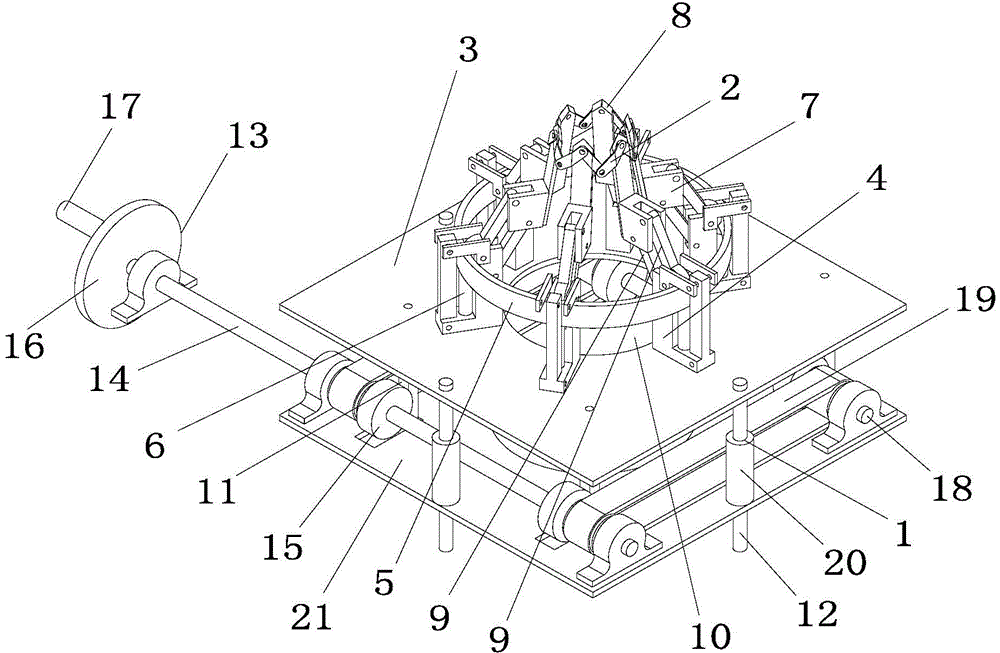

[0032] A variable-diameter impact plunge-cutting ring-shaped banana combing device, including a lifting frame 1 and at least three cutting units, the lifting frame 1 has a workbench 3 and a lifting mechanism for lifting and lowering the workbench, and the cutting unit Arranged in a ring on the workbench 3;

[0033] The cutting unit includes a parallelogram mechanism, comb cutter group and cutter group synchronous controller;

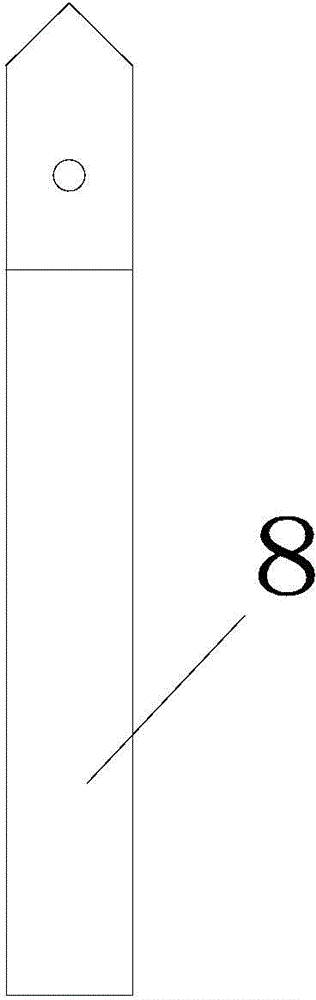

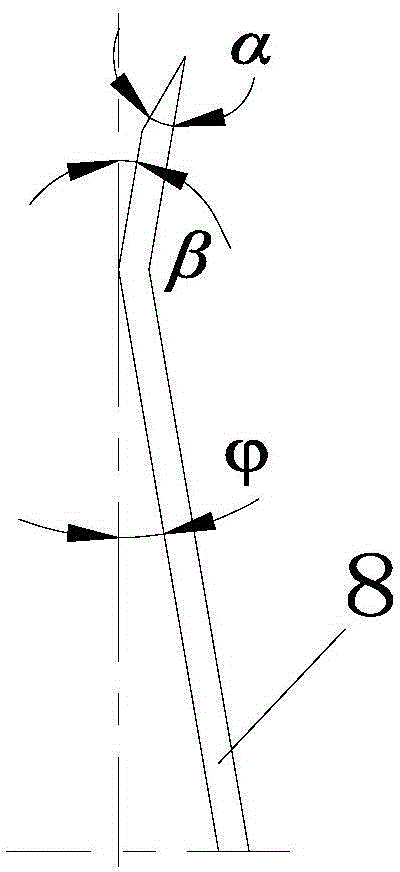

[0034] The comb knife group includes a hard blade 8 and two soft blades 2, and one end of the two soft blades 2 is respectively hinged on the hard blade 8;

[0035] The parallelogram mechanism includes a knife seat 4, a tool mounting head 7 and two connecting rods 9 arranged up and down, the knife seat 4 is fixed on the workbench 3, and the two ends of the two connecting rods 9 are respectively hinged on the knife seat 4 and the tool installation. On the head 7, the hard blade 8 is installed on the tool installation head 7 and protrudes upwards, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com