Intelligent motor power saver

A power-saving and intelligent technology, applied in motor generators/starters, starters of single multi-phase induction motors, AC motor control, etc., can solve problems such as waste of electric energy, low operating efficiency, and low load rate, and achieve guaranteed The effect of safety, prolonging service life and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

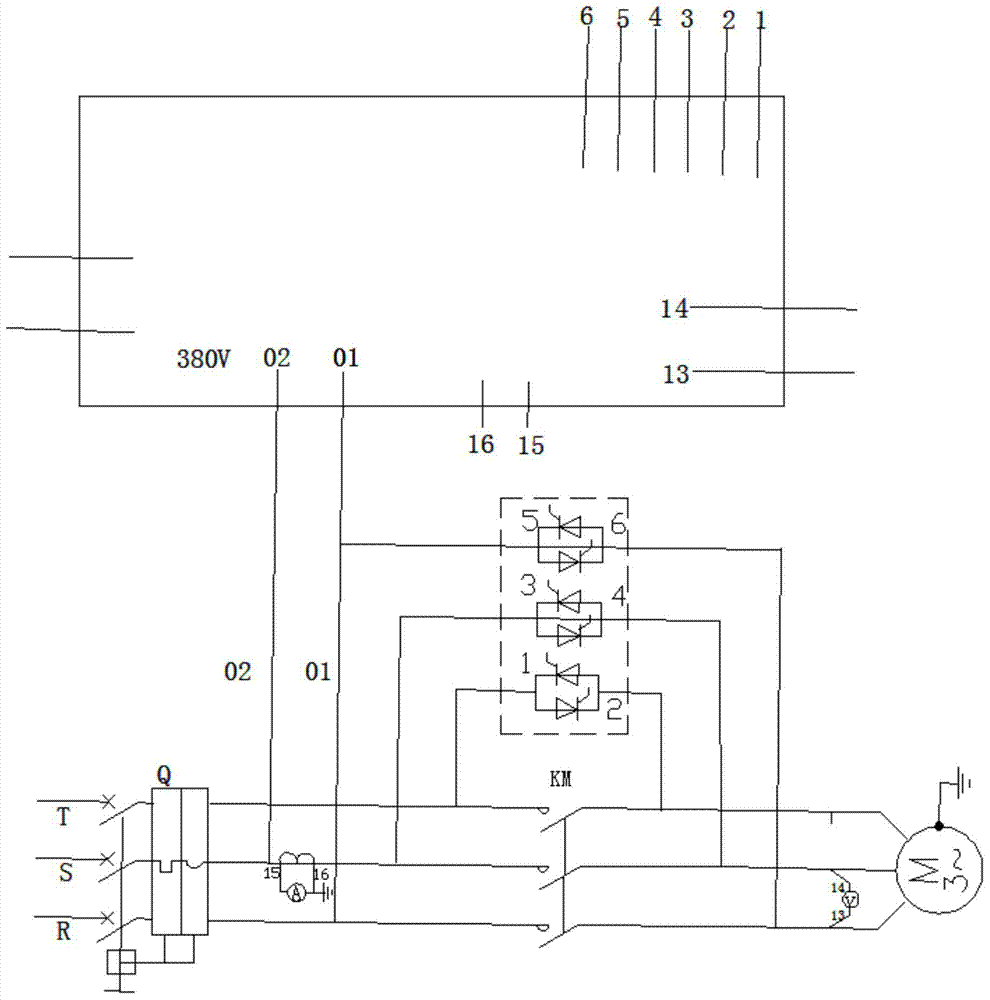

[0019] Example 1: This implementation provides a motor smart power saver, its working principle diagram is as follows figure 1 As shown, RST is a 380V voltage input terminal, and the 380V voltage is input to the voltage input interfaces 01 and 02 of the motor smart power saver, and the stable voltage is input to the power supply of the motor through the voltage stabilization feedback interface 13 and 14 .

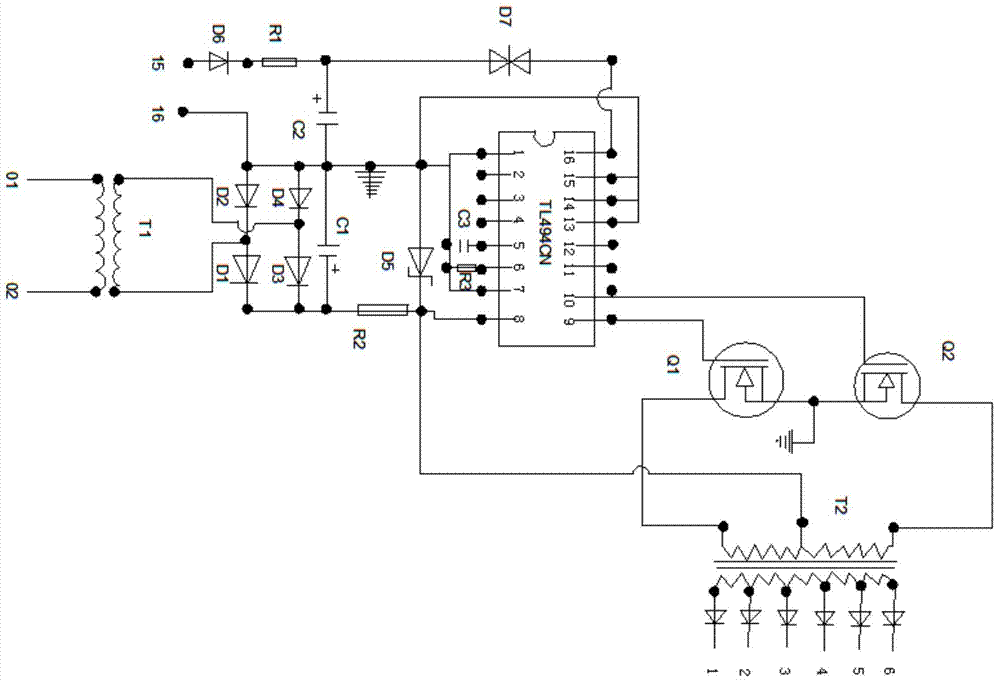

[0020] The circuit diagram of the motor smart power saver provided in this embodiment is as follows figure 2 As shown, it includes a DC voltage regulator circuit, a pulse width modulation circuit, a half-bridge drive circuit, a high-frequency isolation transformer circuit and an overcurrent protection circuit.

[0021] The DC voltage stabilizing circuit includes a transformer T1, a bridge rectifier circuit, a filter capacitor C1, a current limiting resistor R2 and a voltage stabilizing diode D5, the voltage input end of the transformer T1 is connected to the power supply...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com