Novel speed-adjustable cylindrical permanent-magnet eddy-current coupler

A permanent magnet eddy current and coupling technology, which is used in the control of mechanical energy, electrical components, electromechanical devices, etc., can solve the problems of large speed regulating mechanism, waste of magnetic pole action area, unfavorable torque transmission, etc., and is conducive to torque stability. the effect of transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

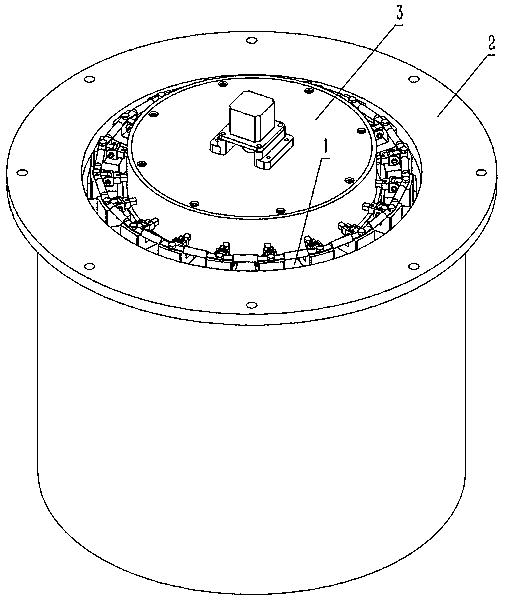

[0017] figure 1 It is a structural schematic diagram of a new adjustable speed cylindrical permanent magnet eddy current coupling designed by the present invention, which is composed of an inner rotor 1, an outer rotor 2 and a speed regulating mechanism 3.

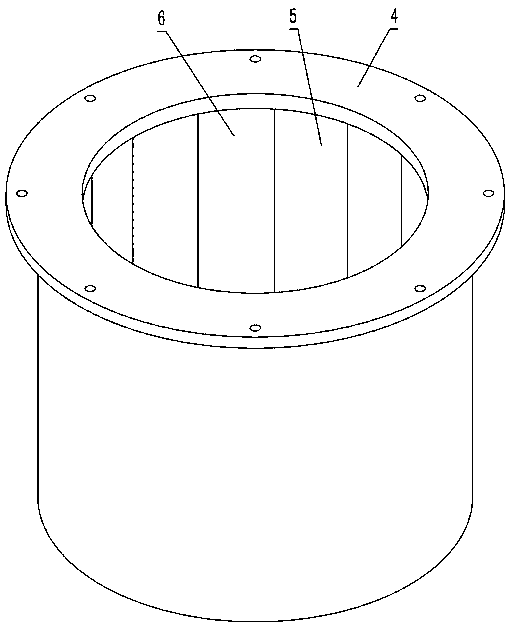

[0018] figure 2 It is a structural schematic diagram of the outer rotor of a new type adjustable speed cylindrical permanent magnet eddy current coupling designed by the present invention, which is composed of an outer rotor base 4, an N-type permanent magnet 5, and an S-type permanent magnet 6. The outer rotor base 4 is a cylindrical structure with an inlaid groove inside the cylinder, and one end of the outer rotor base 4 is designed with a flange structure for connecting with the input shaft. N-type permanent magnets 5 and S-type permanent magnets 6 are alternately inlaid in the inlay groo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com