Method and apparatus for active front end filter capacitor degradation detection

A filter capacitor, degradation detection technology, applied in the field of detection of filter capacitor degradation in motor drives, power conversion system filter capacitor degradation, can solve frequent disconnection downtime, evaluate input filter capacitor performance and any degradation difficulties, capacitor degradation And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

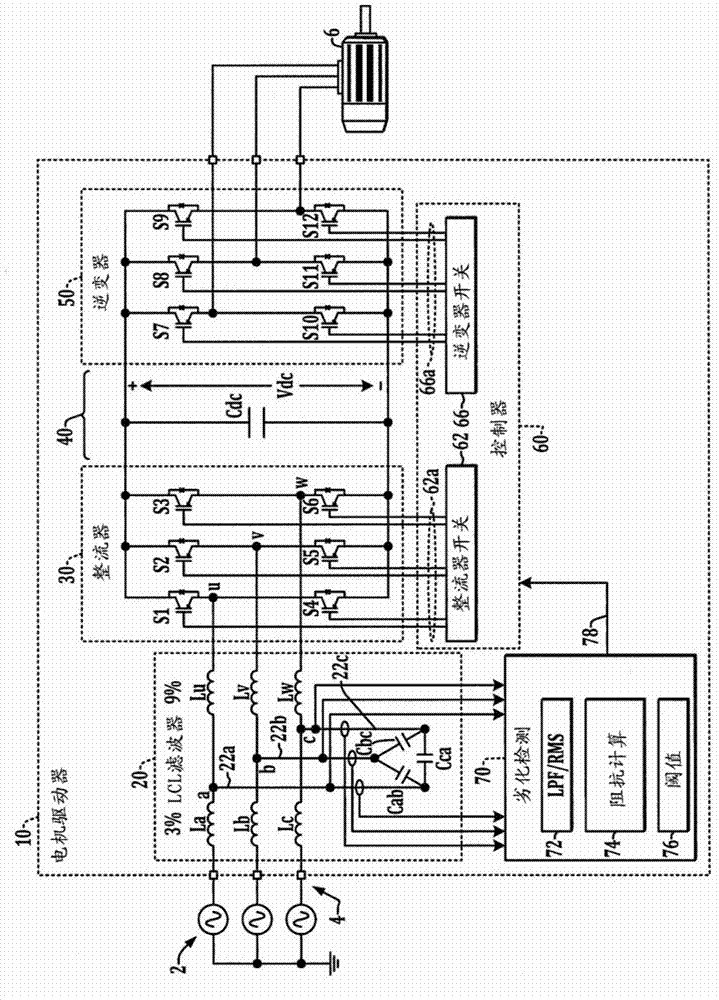

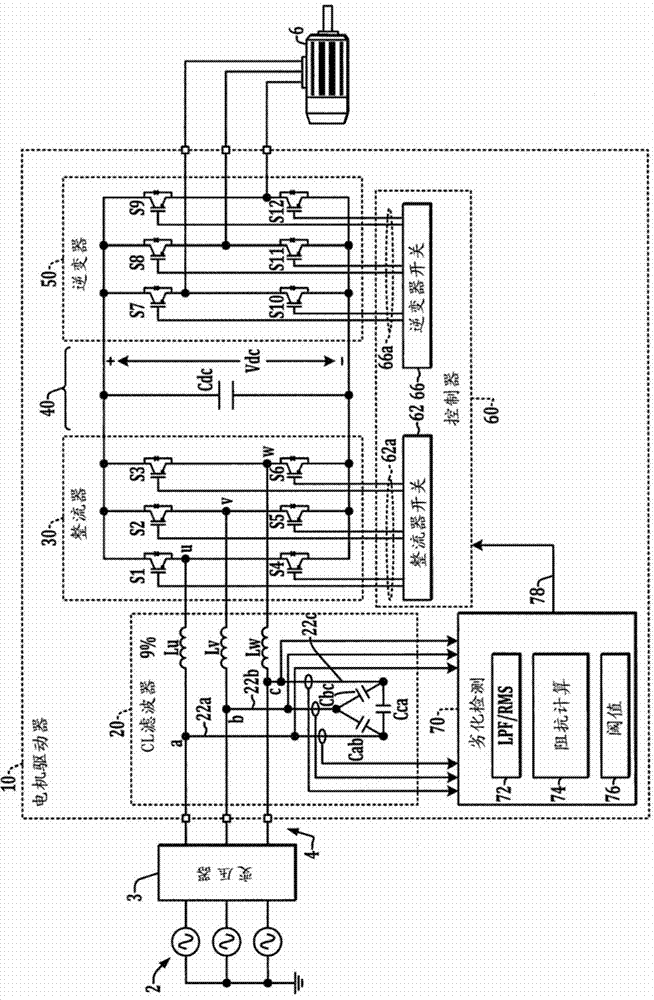

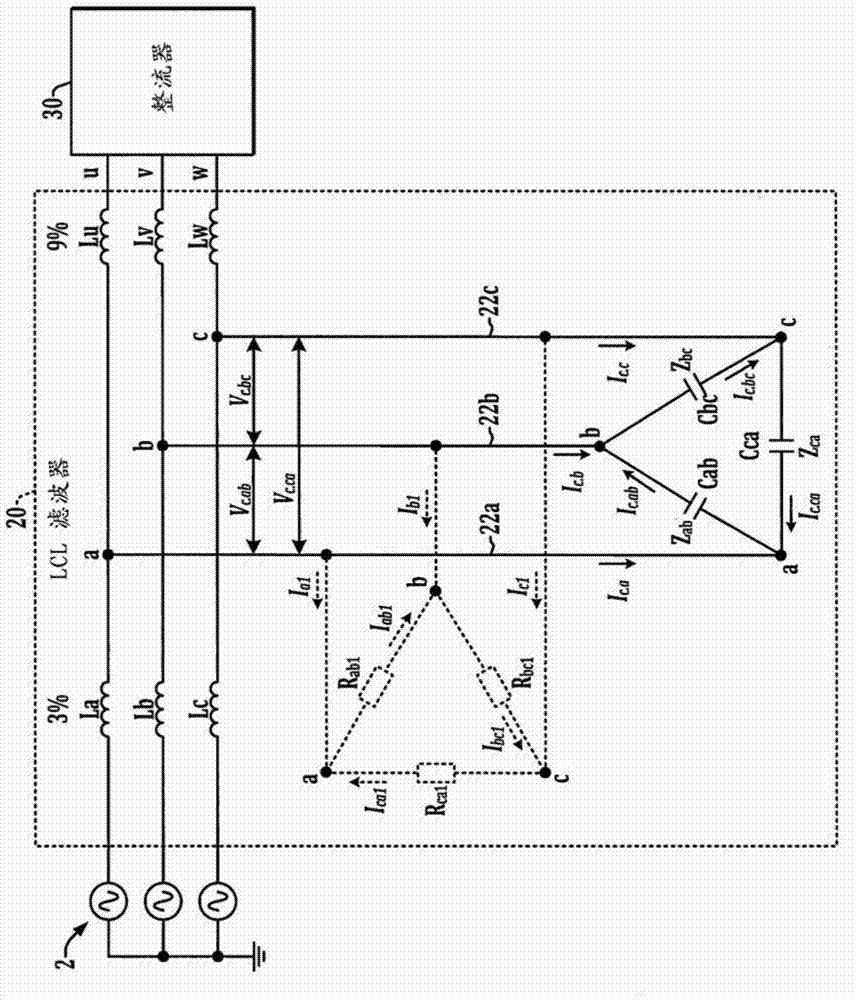

[0018] Referring now to the drawings, several embodiments or implementations will be described below in conjunction with the drawings, wherein like reference numerals refer to like elements throughout, and wherein various features are not necessarily drawn to scale. Techniques and apparatus for detecting degradation of power conversion system filter capacitors connected in a delta configuration are disclosed. These aspects of the present disclosure may find application in association with active front end (AFE) motor drives as well as other forms of power conversion systems. Furthermore, although shown in the context of a three-phase input device, the disclosed concepts can be employed in power conversion systems having any number of input phases where the input filter includes at least one delta-connected filtering capacitor circuit.

[0019] The disclosed techniques and apparatus advantageously facilitate the calculation and monitoring of input filter capacitor values (ie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com