Fuse protector

A technology of fuses and fuses, which is applied in the direction of electrical components, circuits, emergency protection devices, etc., and can solve problems such as inability to complete drilling and tapping and product assembly, complicated procedures for riveting-welded outer end caps, and increased manufacturing costs. , to achieve the effect of eliminating poor conductive contact, original and novel design concept, and solving the effect of not being resistant to high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in detail below in combination with specific embodiments.

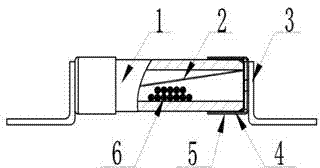

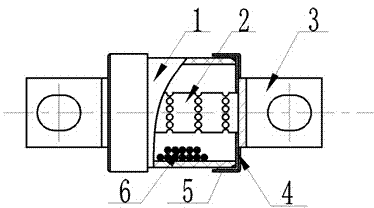

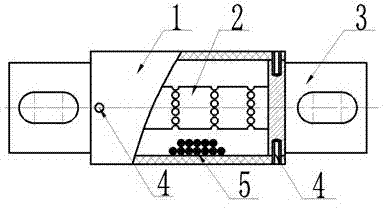

[0022] see Figure 4 , Figure 5 , a fuse, comprising an insulating tube body 1, the insulating tube body 1 is a round or rectangular shape made of ceramic or resin organic synthetic material, a fuse piece 2 is arranged inside the insulating tube body 1, and the fuse piece 2 is made of silver, Wire-shaped or strip-shaped thin strips of copper, aluminum or low-melting point alloys are respectively connected to terminals 3 at both ends of the fuse 2, and the other end of the terminals 3 protrudes from the insulating tube body 1, and each of the terminals 3 Positioning gaskets 4 for fixing the connection terminals 3 are sleeved respectively, each connection terminal 3 has a concave notch, and the positioning gasket 4 is provided with a long hole which can be clamped in the concave notch 3, and the long hole After being clamped in the concave gap, the edge of the positionin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com