Fuel gas injecting and mixing device applied to multi-point injection fuel gas engine

A gas engine, injection mixing technology, applied in combustion engines, internal combustion piston engines, engine components, etc., can solve problems such as uneven fuel mixing and leakage, improve performance and life, improve safety, and solve uneven fuel mixing. and the effect of leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

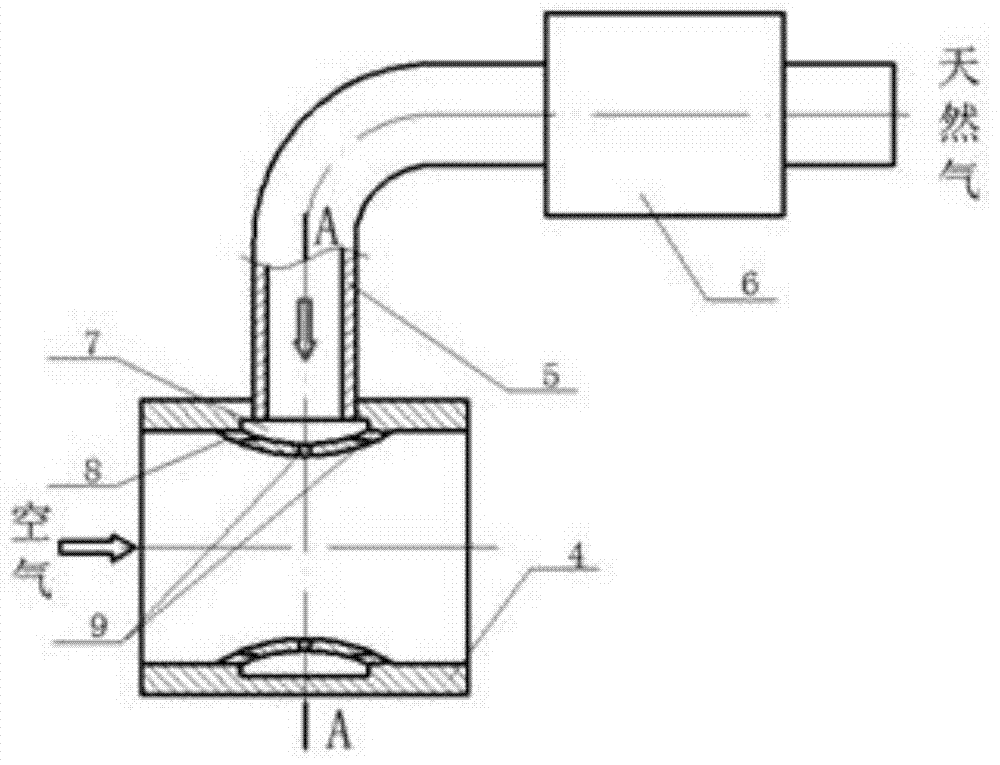

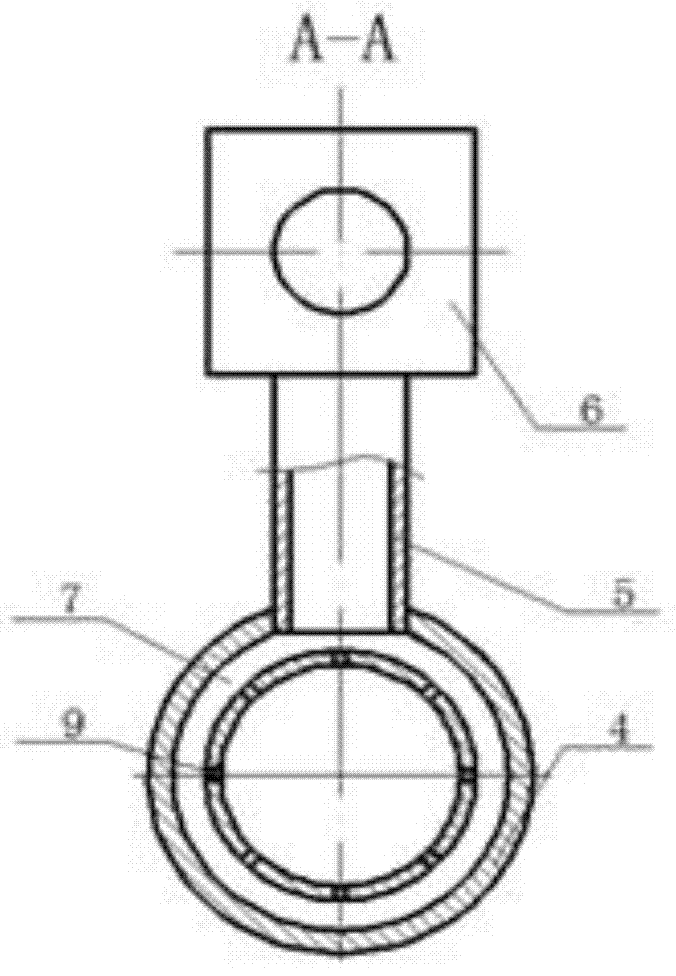

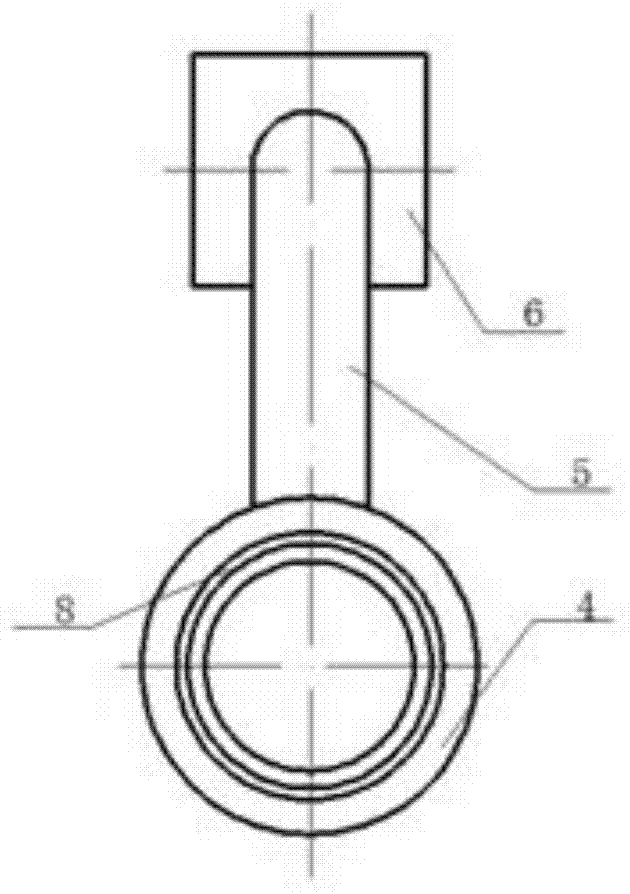

[0024] As shown in Fig. 1 (a)-(c), the gas injection mixing device comprises: gas injection valve 6, its function is according to the operating condition of engine, the injection pressure gas of timing and quantity, and ring groove-porous gas mixer 4 , its function is to realize the uniform mixing of gas and air through the primary mixing method of the annular primary mixing chamber 7 and the secondary mixing method of the small nozzle hole 9, so as to prevent the formation of a local area of excessive heat load inside the combustion chamber due to uneven gas mixing, so as to improve the performance of the engine. The performance and service life of the fuel tank are improved, and by controlling the injection time, the air at the end of the air intake can sweep away the gas in the annular mixing chamber, so as to prevent the gas from escaping into the intake...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com