Drill rod hole sealing device for coal mine punching

A sealing device, drill pipe hole technology, applied in drill pipe, sealing/isolation, drill pipe, etc., can solve the problems of harsh punching site environment, affecting collection effect, poor sealing between drill pipe and collection device, etc. The effect of a good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

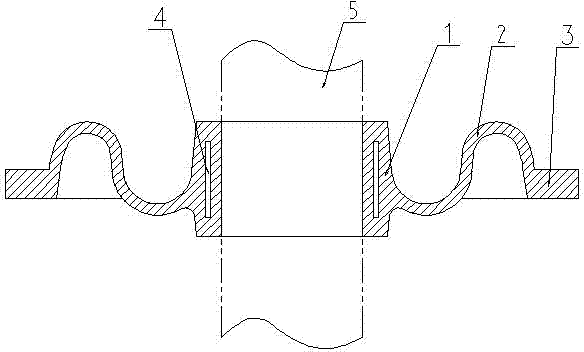

[0008] Such as figure 1 As shown, a drill pipe hole sealing device for coal mine punching, the sealing device is composed of a sealing part 2 and a fixing part 3 connected around the sealing part 2, the fixing part 3 is fixedly connected with the drill pipe hole around, and the sealing part 2 is a corrugated structure made of elastic material with continuous crests and troughs. The sealing part 2 is provided with an annular sealing lip 1 for the punching drill rod 5 to pass through. The sealing surface of the sealing lip 1 and the punching drill rod 5 The outer circumferential surface of the sealing lip 1 is matched with a support frame 4 inside the sealing lip 1 .

[0009] The sealing device is connected with other collecting devices through the fixing part 3 for cooperative use, and the fixing part 3 may adopt a flange structure.

[0010] The sealing surface of the sealing lip 1 is provided with wear-resistant elements, which may be copper sleeves, packings and the like.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com