Combined wooden door capable of being dismounted and mounted

A technology for wooden doors and core boards, applied in the direction of door leaves, corner joints/side joints, etc., which can solve the problems of deformation, warping, cracking, expansion, shrinkage and other problems of wood doors, so as to maintain the overall appearance and have a large market demand , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

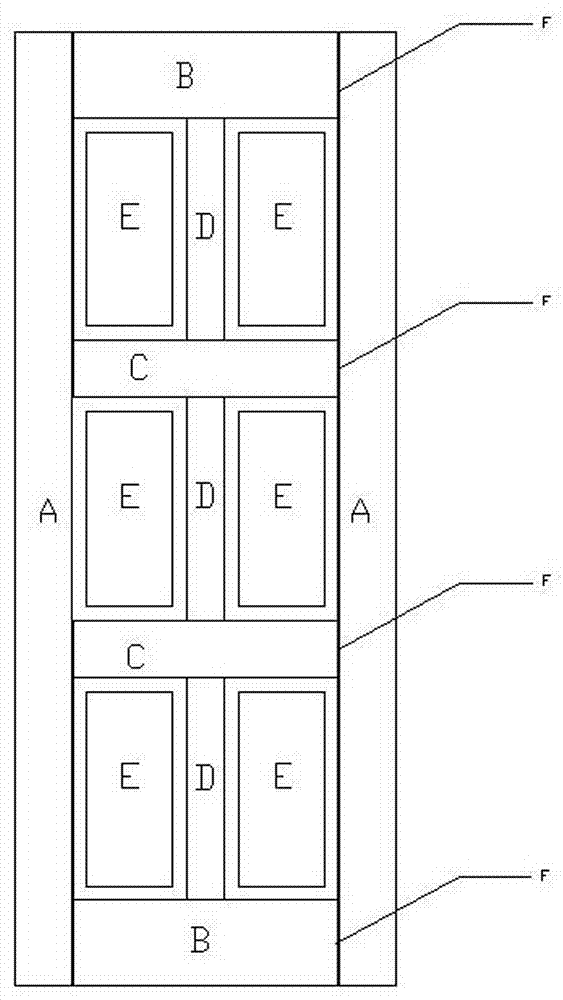

[0012] A detachable composite wooden door, which consists of a core board (E), a door edge (A), a head (B), a vertical frame (C, D) and other components, and is characterized in that: the core board (E) is located In the middle position, the door edge (A) is located on the left and right sides of the core board (E), and the end (B) is located at the upper and lower ends of the core board (E). The core board (E) is composed of multiple small boards, and the middle Connect and fix the vertical beams (C, D), the core board (E) and the door edge (A), the beam head (B), and the vertical beams (C, D) are connected with concave-convex grooves, the door edge (A) and the beam head ( B) Groove milling, milling process line type, core plate (E) milling convex groove and process line type, and then inserted into the groove of door edge (A) and end head (B), core plate (E), door edge (A) There is a natural seam (F) in the connection between , 杩 head (B), and vertical beams (C, D).

Embodiment 2

[0014] There is a natural seam (F) in the connection between the core board (E), the door edge (A), the head (B), and the vertical beams (C, D). There is no need to apply glue or nails during assembly, each part is independent, and the craft seam lines at the contact points are beautiful. When the parts shrink or expand, there is no effect at all, and the change will not be seen. There is no contact point between the parts of the traditional process cracking phenomenon.

Embodiment 3

[0016] The screw holes on the door side (A) are drilled with a stepped drill bit to get through the concentric holes. The door side (A) has a small hole on the inside and a large hole on the outside. The blind hole of the hammer head (B) is deeper than the hammer nut rod 2-3mm, the connection between the door edge (A) and the head (B) is positioned with a round bar tenon, and the vertical head screw is used for connection.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com