A closed pipeline system for corrugated paper production and water circulation

A technology of water circulation and closed pipe, applied in the field of papermaking, can solve the problems of no closed wastewater circulation pipe, disadvantageous centralized treatment of wastewater, and inability to recycle and reuse, and achieve the effect of improving the recycling rate, reducing operating costs, and having less equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

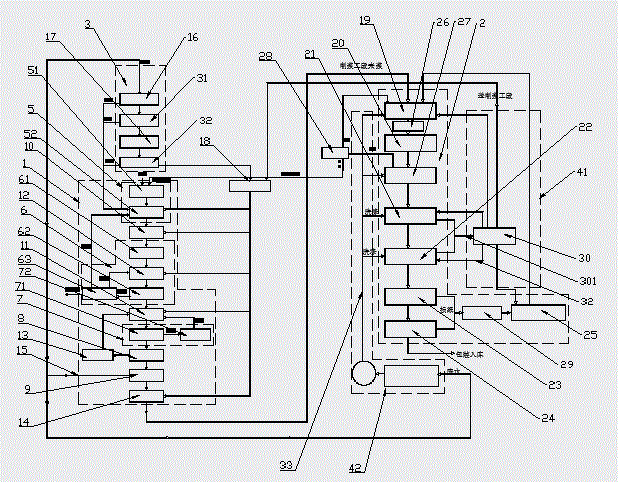

[0047] Such as figure 1 As shown, a closed pipeline system for corrugated paper production and water circulation in the present invention includes a pulping system 1, a papermaking system 2 and a wastewater treatment system; the wastewater treatment system includes a pulping section wastewater treatment system 3 and a papermaking section wastewater treatment system system, the wastewater treatment system 3 of the pulping workshop and the wastewater treatment system of the papermaking workshop are respectively connected with the pulping system 1 and the papermaking system 2 through pipelines to form a closed wastewater treatment circulation pipeline.

[0048] The pulping system 1 includes a crushing system 5, a high-concentration screening system 6, a low-concentration screening syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com