Nickel electroplating method for NdFeB magnets

A neodymium-iron-boron and nickel electroplating technology is applied in the field of nickel-plating of neodymium-iron-boron magnets, which can solve the problems such as the magnetic properties of neodymium-iron-boron magnets are greatly reduced, the uniform distribution of coating thickness is poor, and the magnetic properties are adversely affected, so as to improve the uniform distribution good magnetic properties, and the effect of eliminating the decline of magnetic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

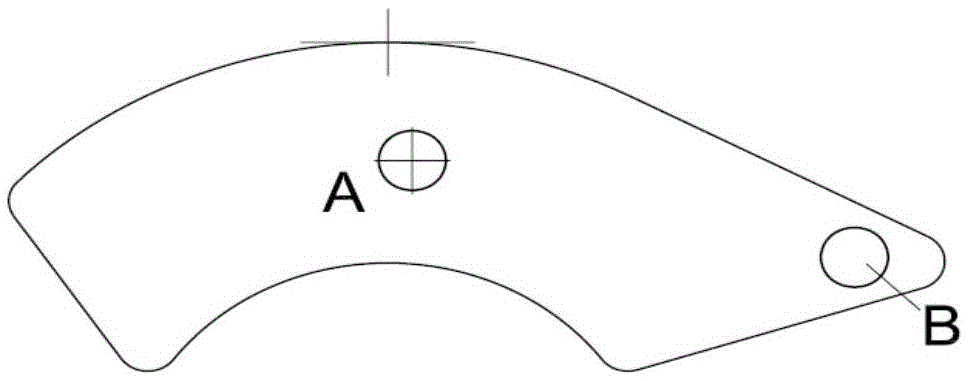

Image

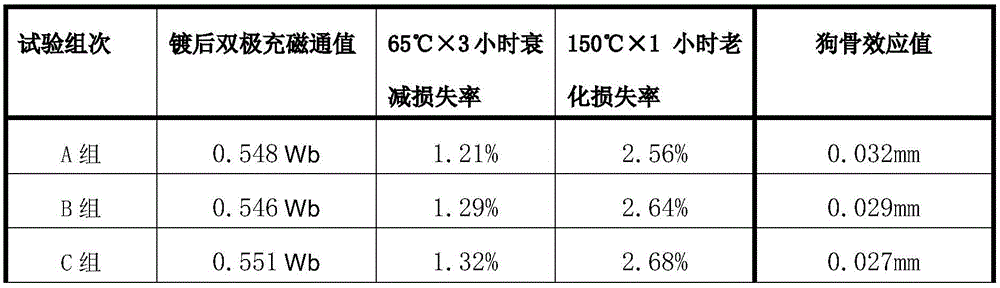

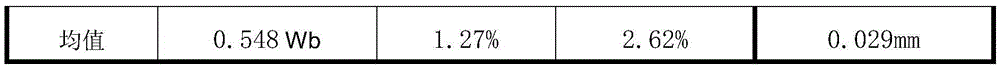

Examples

Embodiment 1

[0021] Embodiment one: a kind of NdFeB magnet electroplating nickel method, comprises the following steps:

[0022] ① Pretreatment of NdFeB magnets;

[0023] ②Nickel pre-plating: put the pre-treated NdFeB magnet into the first nickel electroplating solution for pre-nickel plating for 3500 seconds, in which the first nickel electroplating solution is composed of nickel sulfate, boric acid, and sodium succinate , sodium carboxyethylsulfonate and water, the mass volume concentration of nickel sulfate is 250 g / L, the mass volume concentration of boric acid is 40 g / L, the mass volume concentration of succinate sodium salt is 5 mg / L, carboxylate The mass volume concentration of sodium ethylsulfonate is 5 mg / liter, the current density is 0.2 ampere / square decimeter in the pre-nickeling process, the temperature of the first electroplating nickel solution is 45 degrees Celsius, and the pH value is 4.1;

[0024] ③ Use deionized water to clean the pre-nickel-plated NdFeB magnet several ...

Embodiment 2

[0037] Embodiment two: a kind of NdFeB magnet electroplating nickel method, comprises the following steps:

[0038] ① Pretreatment of NdFeB magnets;

[0039] ②Nickel pre-plating: put the pre-treated NdFeB magnet into the first nickel electroplating solution for pre-nickel plating for 3500 seconds, in which the first nickel electroplating solution is composed of nickel sulfate, boric acid, and sodium succinate , sodium carboxyethylsulfonate and water, the mass volume concentration of nickel sulfate is 250 g / L, the mass volume concentration of boric acid is 40 g / L, the mass volume concentration of succinate sodium salt is 5 mg / L, carboxylate The mass volume concentration of sodium ethylsulfonate is 5 mg / liter, the current density is 0.2 ampere / square decimeter in the pre-nickeling process, the temperature of the first electroplating nickel solution is 45 degrees Celsius, and the pH value is 4.1;

[0040] ③ Use deionized water to clean the pre-nickel-plated NdFeB magnet several ...

Embodiment 3

[0059] Embodiment three: this embodiment is basically the same as embodiment two, and the difference is only that in this embodiment, the pretreatment process includes the following steps:

[0060] ①-1 Pickling: use dilute nitric acid solution as the pickling solution to pickle the NdFeB magnet;

[0061] ①-2 Washing: Use deionized water to clean the pickled NdFeB magnet several times. During the cleaning process, ultrasonic cleaning is provided. The ultrasonic power is 2000W and the frequency is 60KHz;

[0062] ①-3 Put the washed NdFeB magnet into the electrolytic tank for electrolytic treatment. The electrolytic treatment time is 450 seconds. The electrolyte is composed of sodium hydroxide, sodium carbonate and water, and the mass volume concentration of sodium hydroxide is 60 grams. / liter, the mass volume concentration of sodium carbonate is 40 grams per liter, and the current density is 0.7 amperes / square decimeter in the electrolytic treatment process, and the electrolyt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com