A kind of surface functionalized micro-nano polymer gel particle and preparation method thereof

A surface functionalization and polymer technology, applied in the field of new materials, can solve the problems of complex preparation process of micro-nanoparticles, weak functional group reactivity, single functional group, etc., to achieve uniform particle size, broad application value, polymerization simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of micro-nano polymer gel particles: Feed the reaction monomer, polymerization initiator, and solvent into the reactor equipped with nitrogen conduit, condenser, stirrer, and thermometer at one time according to the set ratio, fully dissolve and mix evenly ; Nitrogen and oxygen exhaust for 15-30min; heat the solution system in a constant temperature water bath, the temperature is 45-120°C, the time is 5-600min, the stirring rate is 0-450rpm; after the reaction is completed, the obtained product is separated by a high-speed centrifuge, The rotation speed is 5000-12000rpm; the centrifuged product is washed with a solvent, centrifuged and washed again, and repeated 3-5 times; the final centrifuged product is placed in a vacuum oven and dried at 60°C until it reaches a constant weight.

[0060] Wherein, the reactive monomer includes: methylene succinic anhydride, N-vinylpyrrolidone, and a crosslinking agent. Preferably, the reactive monomer consists o...

Embodiment 1

[0079] Methylene succinic anhydride 0.65g, N-vinylpyrrolidone 0.25g, divinylbenzene 0.3g, dibenzoyl peroxide 0.01g, butyl acetate 72mL, cyclohexanone 12mL, n-hexane 15mL, add to 250mL Fully dissolve in a three-necked flask; pass nitrogen and oxygen for 20 minutes; heat the solution system in a constant temperature water bath to initiate polymerization reaction, keep the temperature at 85°C, and complete the reaction for 8 hours. The product was separated with a centrifuge at 5000 rpm, washed with butyl acetate, centrifuged again and washed three times; the final centrifuged product was placed in a vacuum oven and dried at 60°C until it reached a constant weight.

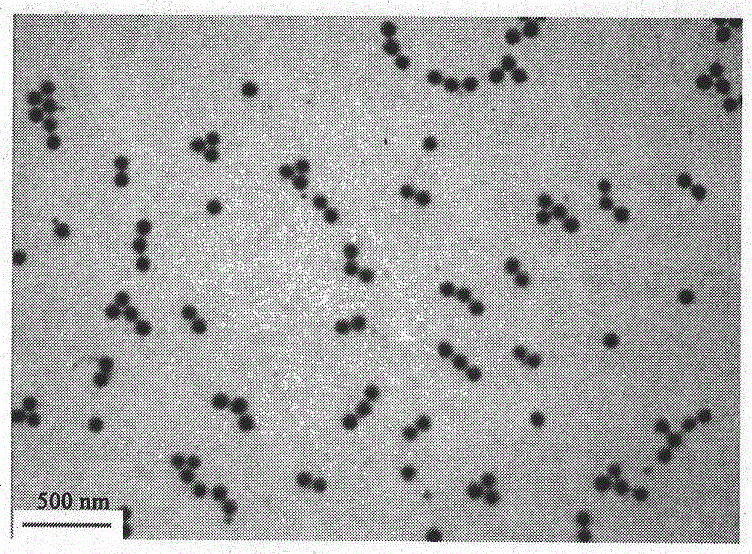

[0080] The transmission electron micrograph of gained micronano polymer gel particle sees figure 1 . The average particle diameter of the particles is 76nm, and the particle size distribution index is 1.05, which is close to monodispersity.

Embodiment 2

[0082] Other conditions were the same as in Example 1, except that the amounts of methylene succinic anhydride, N-vinylpyrrolidone, and divinylbenzene were 1.5 g, 0.8 g, and 1.2 g, respectively.

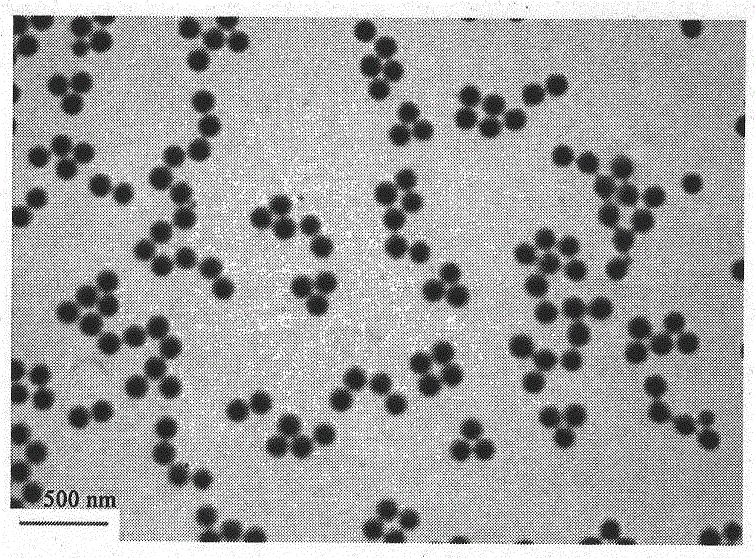

[0083] The transmission electron micrograph of gained micronano polymer gel particle sees figure 2 . The average particle size of the particles is 115nm, and the particle size distribution index is 1.03, which is close to monodispersity, indicating that the particle size of the polymer gel particles increases with the increase of the monomer concentration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com