A chromium-molybdenum steel pipe bundle and tube sheet maintenance process

A steel pipe bundle and process technology, applied in the field of chrome-molybdenum steel pipe plate maintenance, can solve the problems of poor welding quality and high welding cost of chrome-molybdenum steel pipe bundle and tube plate maintenance, and achieve small cold shrinkage coefficient, small heating range, and post-weld residual The effect of less stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

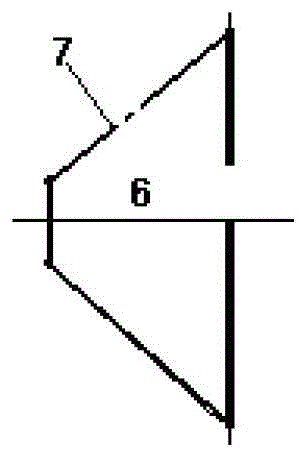

Image

Examples

Embodiment

[0080] The E201 reforming gas heat exchanger of a methanol plant, the tube sheet and tube bundle are made of 13Cr1Mo44, the tube bundle and the shell are connected as a whole, there are tube sheets at both ends, the tube sheet thickness is 35mm, the diameter is 1200mm; the tube bundle diameter is 32mm, the thickness is 3.0mm, 400 pieces in total. The working pressure inside the tube bundle is 2.5Mpa, the working pressure outside the tube bundle is 9Mpa, the temperature at the high temperature end is 250℃, and the temperature at the low temperature end is 150℃. Due to the high pressure and the large temperature difference, 4 tube bundles leak after long-term operation, and the tube sheet produces two lengths. For 20mm cracks, in order to ensure production, two methods are used to repair the leaking tube bundle and tube sheet cracks on site.

[0081] 1. Repair of 4 leaking tube bundles

[0082] 1. Use standard chromium molybdenum steel repair process for repair

[0083] After heatin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com