A kind of preparation method of ultrafine copper sheet

A technology of copper sheet and copper powder, which is applied in the field of ultra-fine copper sheet preparation, can solve the problems of long single production cycle, low output, super large particles or uneven particles, etc., and achieve effective air isolation, uniform size and excellent performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

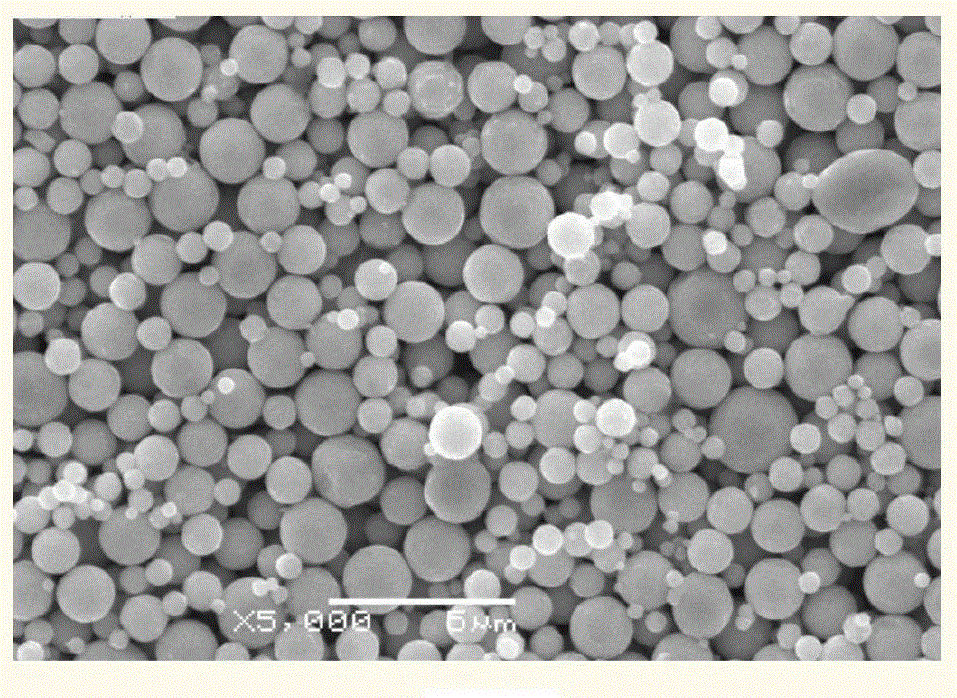

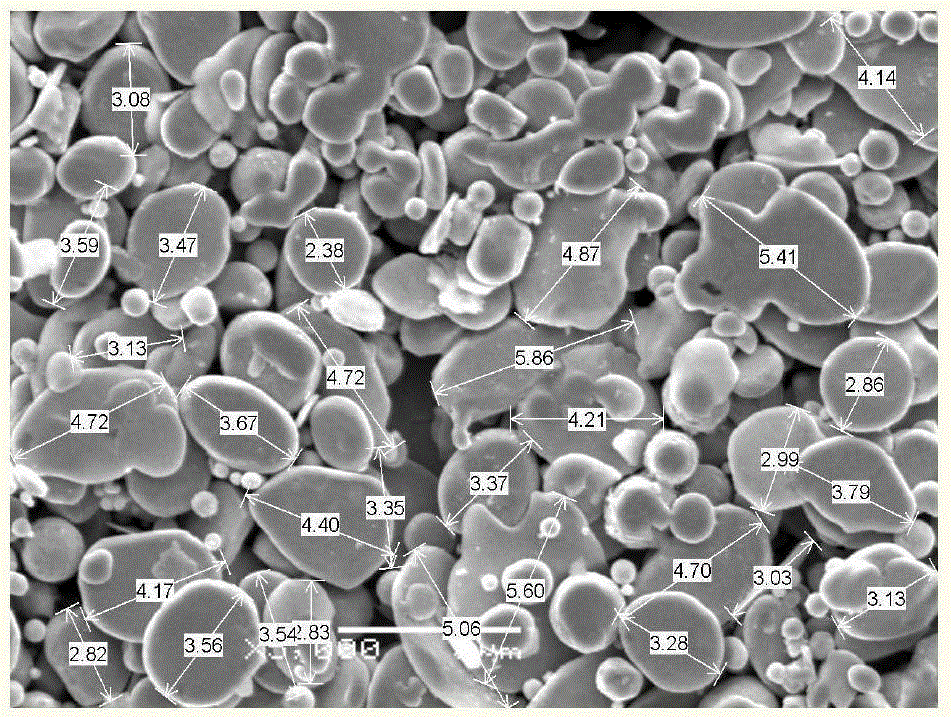

[0046] (1) After classification and anti-oxidation treatment, spherical copper powder with an average particle size of 900nm is used as raw material (the number of large particles above 5um is 0), and 50kg of spherical copper powder is added to a stirring tank equipped with isopropanol for mixing and stirring, and the slurry The concentration is 25%.

[0047] (2) Choose zirconia beads with a size of 0.2 mm as the grinding balls, add 25 kg of grinding balls to a continuous discharge grinder with a volume of 15 L, and set the cold interlayer water temperature of the grinder and the stirring tank to 10°C.

[0048] (3) The stirring speed of the grinding machine is set to 400rpm, and the slurry in the stirring tank is added to the grinding machine by a metering pump. The slurry flow rate is 3.5L / min, and the slurry after grinding is discharged from the grinding machine outlet and collected. a When the stirred tank is emptied, the first pass of grinding is completed.

[0049] (4) S...

Embodiment 2

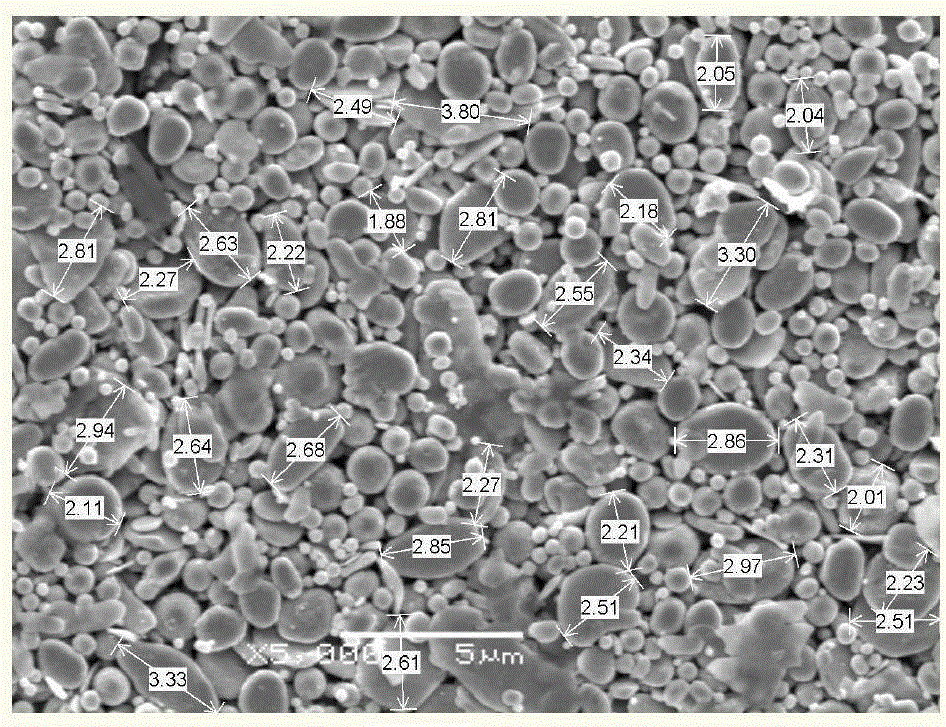

[0052] (1) After classification and anti-oxidation treatment, spherical copper powder with an average particle size of 900nm is used as raw material (the number of large particles above 5um is 0), and 50kg of spherical copper powder is added to a stirring tank equipped with isopropanol for mixing and stirring, and the slurry The concentration is 25%.

[0053] (2) Choose zirconia beads with a size of 0.3mm as the grinding balls, put 25kg of grinding balls into a continuous discharge grinder with a volume of 15L, and set the temperature of the cold interlayer water in the grinder and the stirring tank to 10°C.

[0054] (3) The stirring speed of the grinding machine is set to 400rpm, and the slurry in the stirring tank is added to the grinding machine by a metering pump. The slurry flow rate is 3L / min, and the slurry after grinding is released from the grinding machine outlet and collected. After the stirred tank is emptied, the first grinding pass is completed.

[0055] (4) The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com