Method for selecting copper concentrate from copper ore with high sulfur and arsenic content

A copper concentrate and content technology, applied in the field of smelting, can solve the problems of difficult separation of sulfur arsenic copper ore, difficulty in finding the mineral separation potential range, and difficulty in realizing the separation of copper and arsenic, so as to achieve the effect of promoting sales and smelting recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

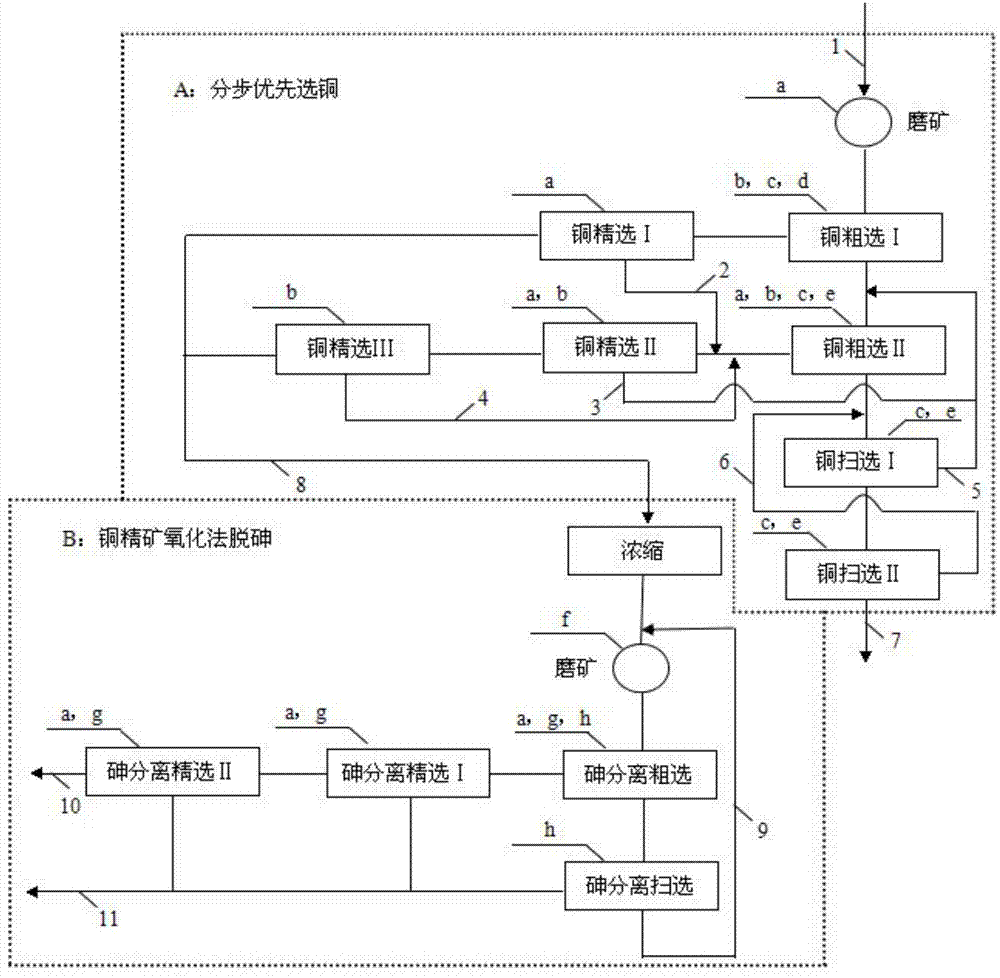

[0014] Example 1: According to the dry weight of each ton of raw ore, add calcium oxide in the ball mill at an amount of 1000g / t, add the crushed raw ore and water to the ball mill at a ratio of 1:1 for grinding, and discharge the material from the ball mill. The ore fineness is -0.074mm, accounting for 60%, and the pH value of the ore pulp is 9.0-10.0. Add 500g / t of water glass, 20g / t of butylammonium black medicine and 10g / t of terpineol oil to the material discharged from the ball mill in sequence, and then perform the first copper roughing operation; then add calcium oxide in sequence The dosage is 1000g / t, the dosage of water glass is 250g / t, the dosage of butyl ammonium black medicine is 10g / t, and the dosage of butyl xanthate is 5g / t, and then the second copper roughing operation is carried out after mixing and slurrying. Add the dosage of butylammonium black medicine 5g / t and the dosage of butyl xanthate 2.5g / t in sequence, stir and adjust the slurry, and then carry ou...

Embodiment 2

[0015] Embodiment 2: According to figure 1 The embodiment of the technological process of the present invention, the test steps, process parameters, and medicament system are exactly the same as those in Example 1. The technological indexes of embodiment 1 and embodiment 2 of the present invention are shown in Table 1. Shown by the implementation result shown in table 1, adopt the inventive method, the low-arsenic copper concentrate copper grade that embodiment 1 obtains is 22.54%, the copper recovery rate is 72.48%, and the arsenic content is 0.46%; The high-arsenic copper concentrate copper grade is 21.09% , the copper recovery rate was 21.17%, and the arsenic content was 2.73%. The copper grade of the low-arsenic copper concentrate obtained in Example 2 was 22.14%, the copper recovery rate was 71.09%, and the arsenic content was 0.42%; the copper grade of the high-arsenic copper concentrate was 20.01%, the copper recovery rate was 20.01%, and the arsenic content was 2.48%....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com