A microwave integrated amplifier circuit and its manufacturing method

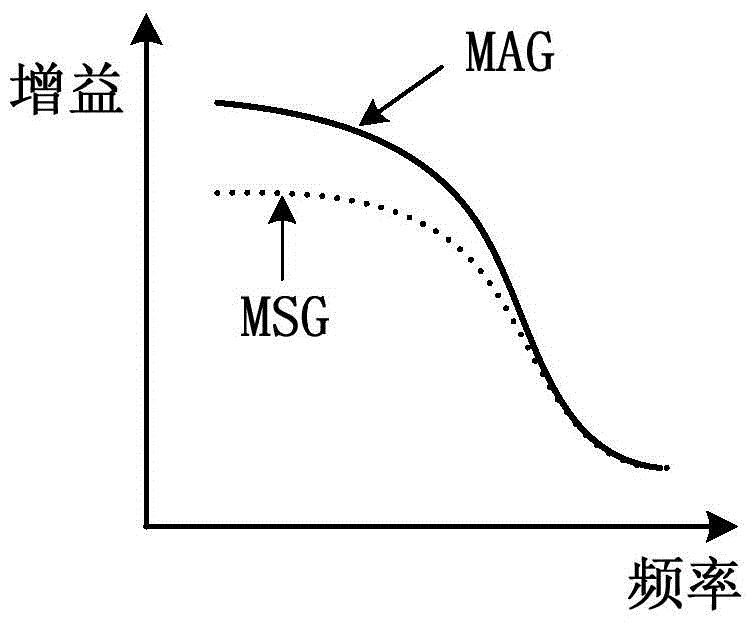

An amplifier circuit and microwave integration technology, applied in the field of microelectronics, can solve the problems of increasing process complexity and cost, relatively high requirements on types and thicknesses, and incompatible processes, so as to reduce process complexity, reduce design difficulty, and improve stability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

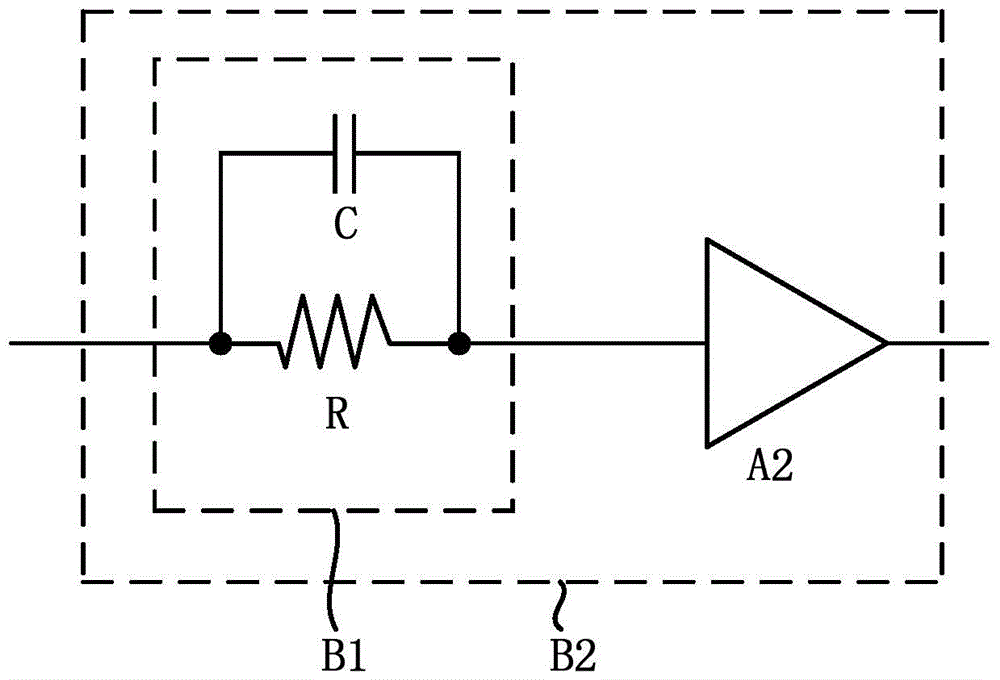

[0070] Embodiment 1 of the present invention provides a microwave integrated amplifier circuit. Figure 2a It is a structural cross-sectional schematic view of a microwave integrated amplifier circuit provided in Embodiment 1 of the present invention. see Figure 2a , the microwave integrated amplifier circuit includes: a gallium nitride high electron mobility transistor 10 and an oscillation stabilization circuit 20, wherein the gallium nitride high electron mobility transistor 10 and the oscillation stabilization circuit 20 have the same substrate 1 and The same epitaxial structure 2 located on the substrate is isolated by the isolation region 31 located in the epitaxial structure 2; the epitaxial structure 2 at least includes a nitride channel layer 2a, located in the nitride channel layer The nitride barrier layer 2b on 2a and the conductive channel 2c with high electron mobility at the interface between the nitride channel layer 2a and the nitride barrier layer 2b; the g...

Embodiment 2

[0082] Embodiment 2 of the present invention also provides a microwave integrated amplifier circuit. Figure 5a It is a structural cross-sectional schematic diagram of a microwave integrated amplifier circuit provided in Embodiment 2 of the present invention. see Figure 5a ,and Figure 2a The difference is that the oscillation stabilization circuit 20 further includes a first dielectric layer 24 , and the first dielectric layer 24 is located between the nitride barrier layer 2 b and the third electrode 23 . Figure 5a It is just a specific example of this embodiment. Figure 5b It is a structural cross-sectional schematic diagram of another microwave integrated amplifier circuit provided by Embodiment 2 of the present invention. see Figure 5b ,and Figure 5a The difference is that the first dielectric layer 24 covers the nitride barrier layer 2 b between the first electrode 21 and the second electrode 22 .

[0083] Further, see Figure 5a and Figure 5b , the first e...

Embodiment 3

[0088] Embodiment 3 of the present invention also provides a microwave integrated amplifier circuit. Figure 6a It is a structural cross-sectional schematic diagram of a microwave integrated amplifier circuit provided by Embodiment 3 of the present invention. see Figure 2a and Figure 6a , on the basis of the first embodiment of the present invention, the oscillation stabilization circuit 20 in the third embodiment of the present invention further includes: a second dielectric layer 25 and a fourth electrode 26, the second dielectric layer 25 is located on the third electrode 23 and on the epitaxial structure 2 between the first electrode 21 and the second electrode 22 and not covered by the third electrode 23, the fourth electrode 26 is located between the first electrode 21 and the second electrode 22 on the second dielectric layer 25 . The rest of the structure of the microwave integrated amplifier circuit in this embodiment and related descriptions are similar to those...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com