Lamp lead-free glass stem

A lead-free glass and stem technology, which is applied in the parts of gas discharge lamps and other directions, can solve the problems such as affecting the overall strength and service life of the exhaust pipe, large shrinkage at the flattened part, and unstable product quality, etc. Simple, low cost and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with drawings and embodiments.

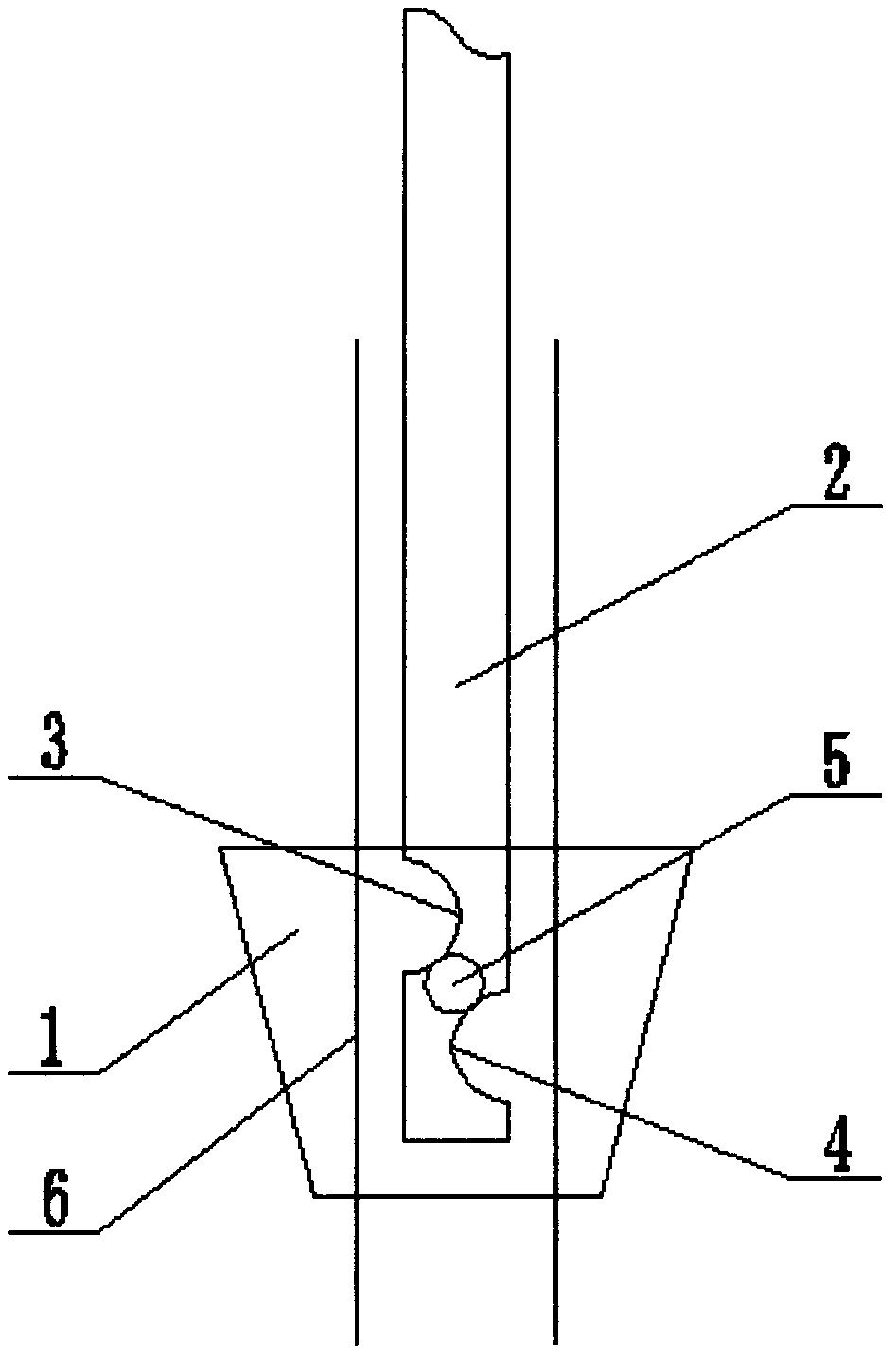

[0013] figure 1 As shown, a lead-free glass stem for a lamp includes a horn pipe 1 and an exhaust pipe 2, the exhaust pipe 2 and the guide wire 6 are connected in the horn pipe 1, and the exhaust pipe 2 of the first section of the horn pipe is provided with The upper and lower clamping sections 3 and 4 are set up and down on the exhaust pipe 2 in a state of unilateral contraction of the intake and exhaust pipe 2. The shrinking directions of the two clamping sections are opposite to each other. The distance between the clamping sections along the direction of the exhaust pipe is 5 mm, and a spherical block 5 is arranged in the exhaust pipe between the two clamping sections.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com