Throttle structure and pressure drop device

A two-stage throttling and valve needle technology, which is applied in valve devices, valve devices for absorbing fluid energy, valve details, etc., can solve problems such as affecting product noise quality, refrigerant easily forming bubbles, affecting heat exchange efficiency, etc. To achieve the effect of reducing the possibility of turbulent vortex formation and shedding, reducing the possibility and improving heat transfer efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

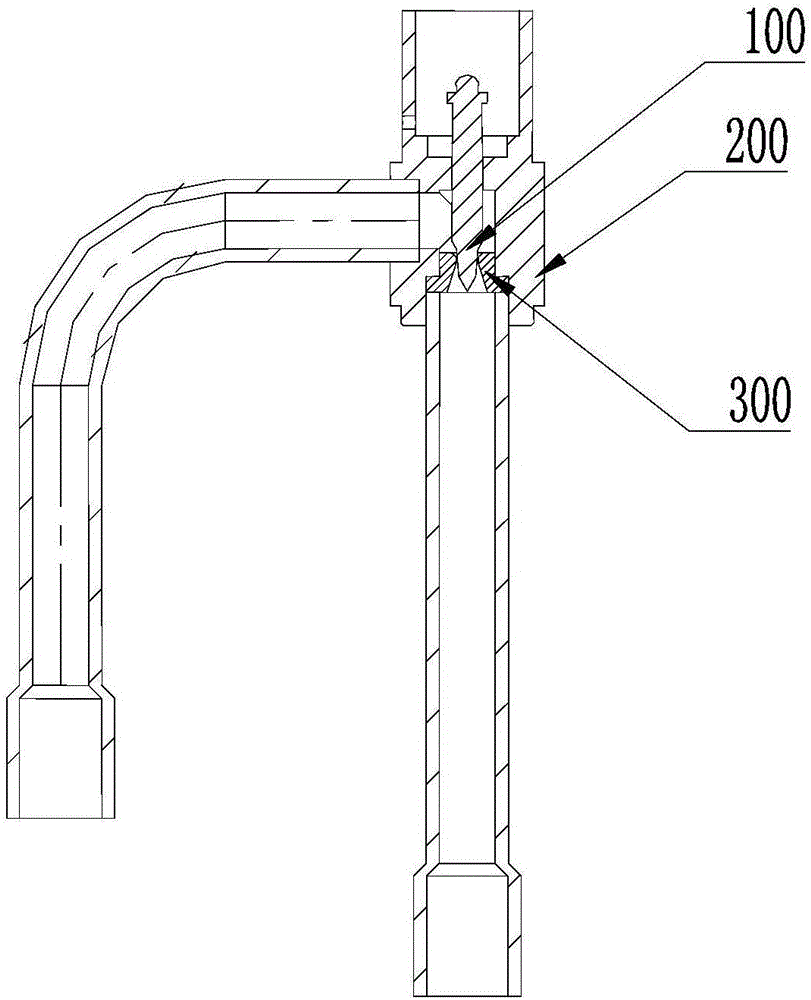

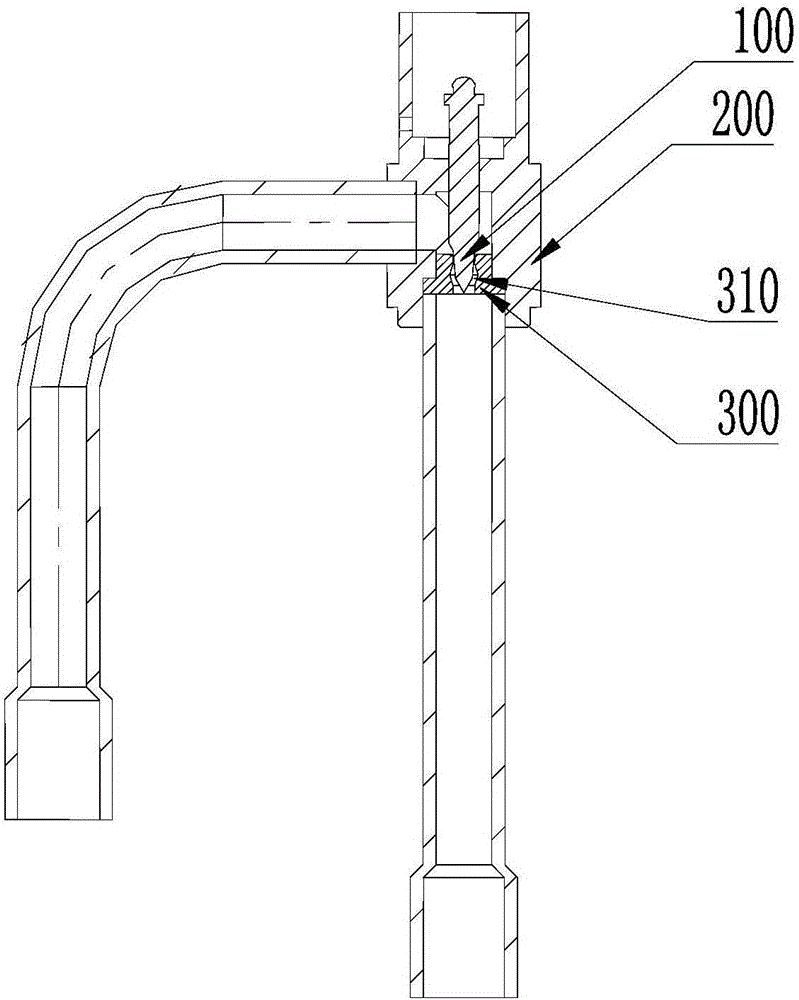

[0019] see figure 2 , an embodiment of the throttling structure provided by the present invention includes a valve needle 100, a valve body 200 and a valve seat core 300, the valve seat core 300 is fixed on the valve body 200, and a smooth transition channel is arranged inside the valve seat core 300 Hole 310. The upper end of the valve needle 100 is cylindrical, the lower end is conical, the through hole 310 is larger in the middle and smaller at the two ends, and the cross-sectional area of the upper and lower ends is smaller than the cross-sectional area of the middle. The shape of the through hole 310 matches the shape of the valve needle 100 , and the valve needle 100 can be inserted into the through hole 310 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com