Imaging lens group

A lens group and lens technology, applied in optical components, instruments, optics, etc., can solve the problems of large image surface, large aperture and good chromatic aberration performance at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

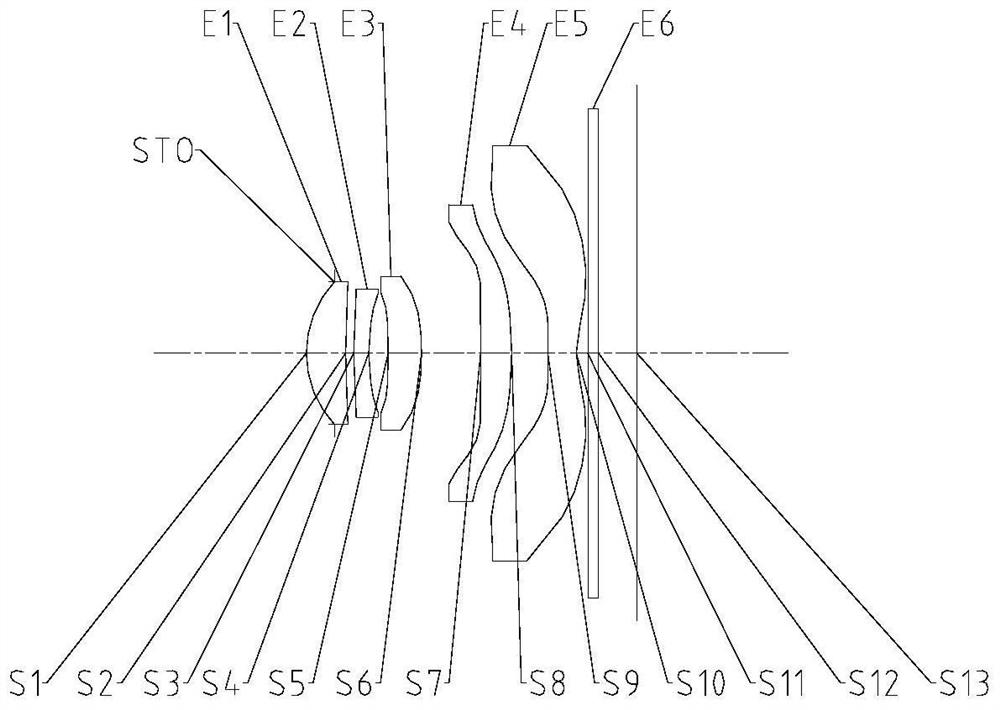

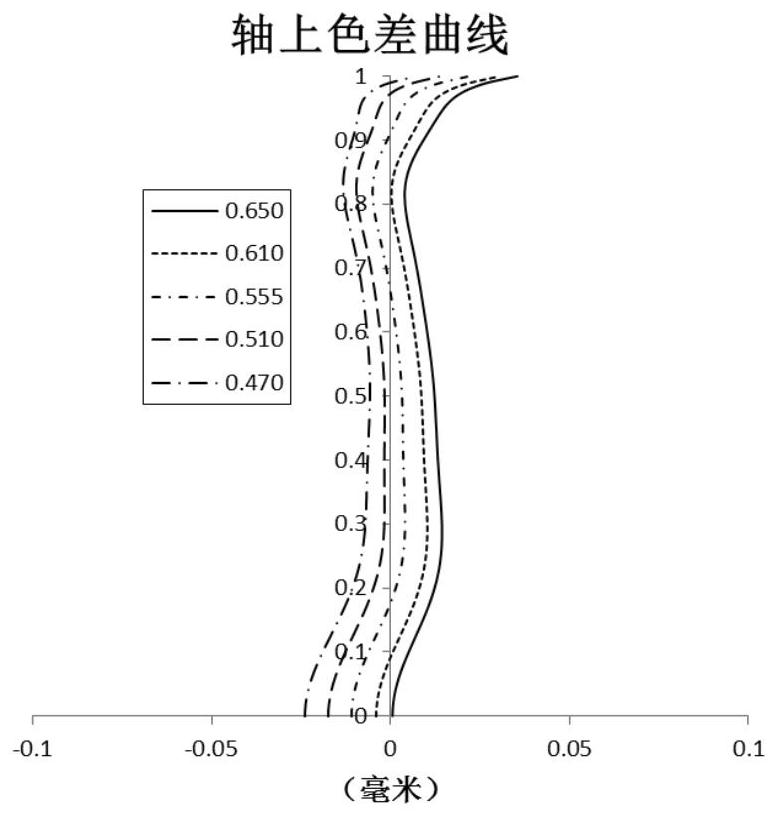

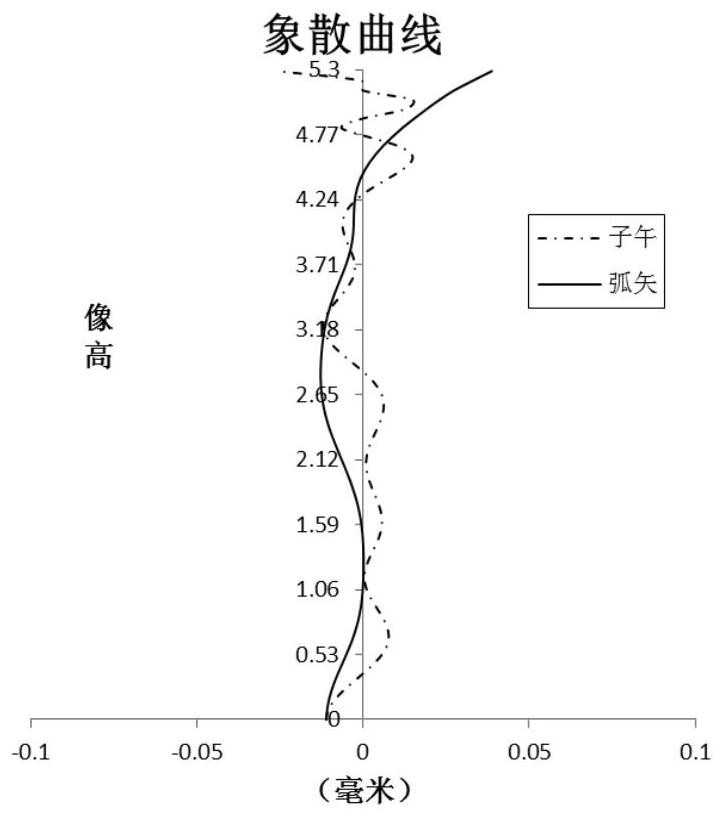

[0049] like Figure 1 to Figure 25 As shown, from the object side to the imaging side, the imaging lens group sequentially includes a first lens with positive refractive power, a second lens with negative refractive power, a third lens with positive refractive power, and a fourth lens with positive refractive power and the fifth lens with negative refractive power; the object side of the first lens is convex, and the imaging side is concave; the object side of the second lens is convex, and the imaging side is concave; the object side of the third lens is concave, and the imaging side is Convex; the object side of the fourth lens is convex, and the imaging side is convex; the object side of the fifth lens is convex, and the imaging side is concave; and at least 3 of the first to fifth lenses are made of glass, and, The axial distance between the object side of the first lens and the imaging surface TTL and the half of the diagonal length of the effective pixel area on the imag...

Embodiment 2

[0063] like Figure 1 to Figure 25 As shown, the imaging lens group sequentially includes from the object side to the imaging side: a first lens with positive refractive power, whose object side is convex, and whose imaging side is concave; a second lens with negative refractive power, whose object side is convex, The imaging side is concave; the third lens with positive power is concave on the object side and the imaging side is convex; the fourth lens with positive power is convex on the object side and the imaging side is convex; with negative power The fifth lens, the object side is convex, and the imaging side is concave; and at least 3 lenses from the first lens to the fifth lens are made of glass, and the Abbe number V1 of the first lens and the A of the third lens The relationship between the shell number V3 and the Abbe number V5 of the fifth lens satisfies: 70<(V1+V3+V5) / 3<85; the air space between the third lens and the fourth lens on the optical axis T34, the fourt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com