Low temperature soaping enzyme and its application in the soaping process of active dyeing

A reactive dyeing and low-temperature soap technology, which is applied in the direction of surface active detergent composition, dyeing method, detergent compounding agent, etc., can solve the problems of low production efficiency, energy consumption, and non-compliance with energy saving and emission reduction, etc., to achieve Improve production efficiency and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

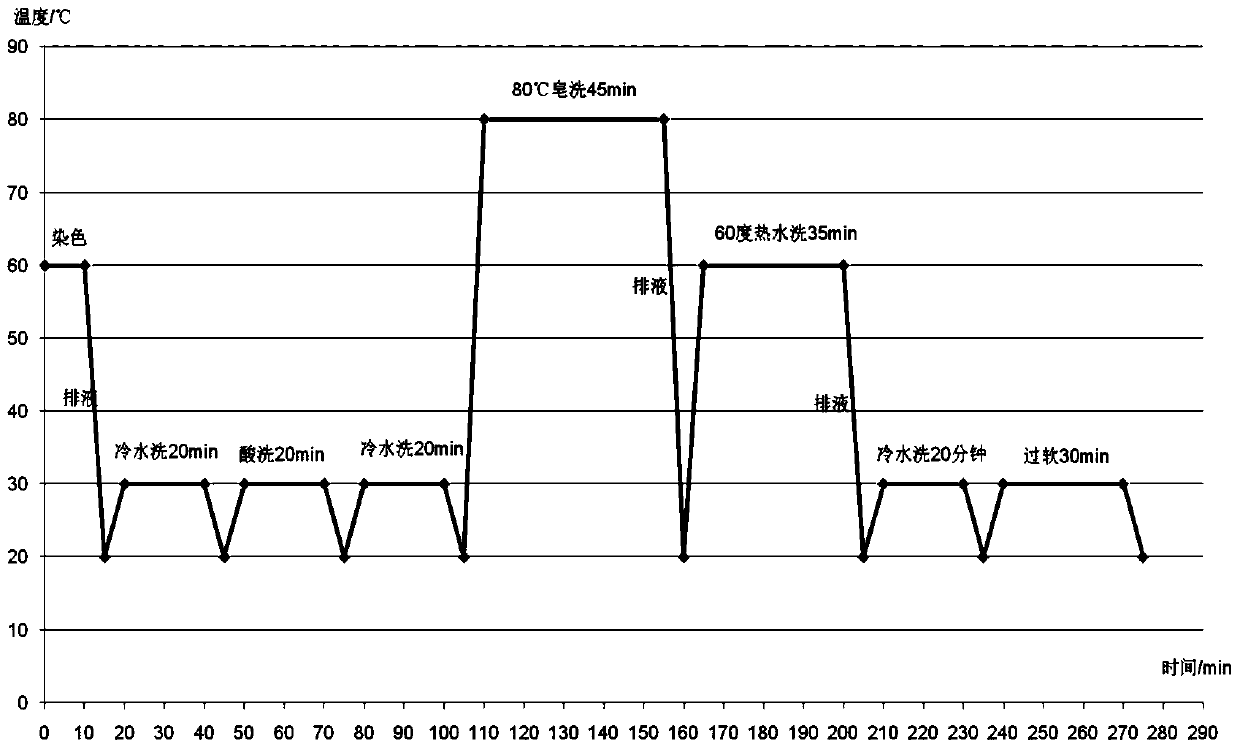

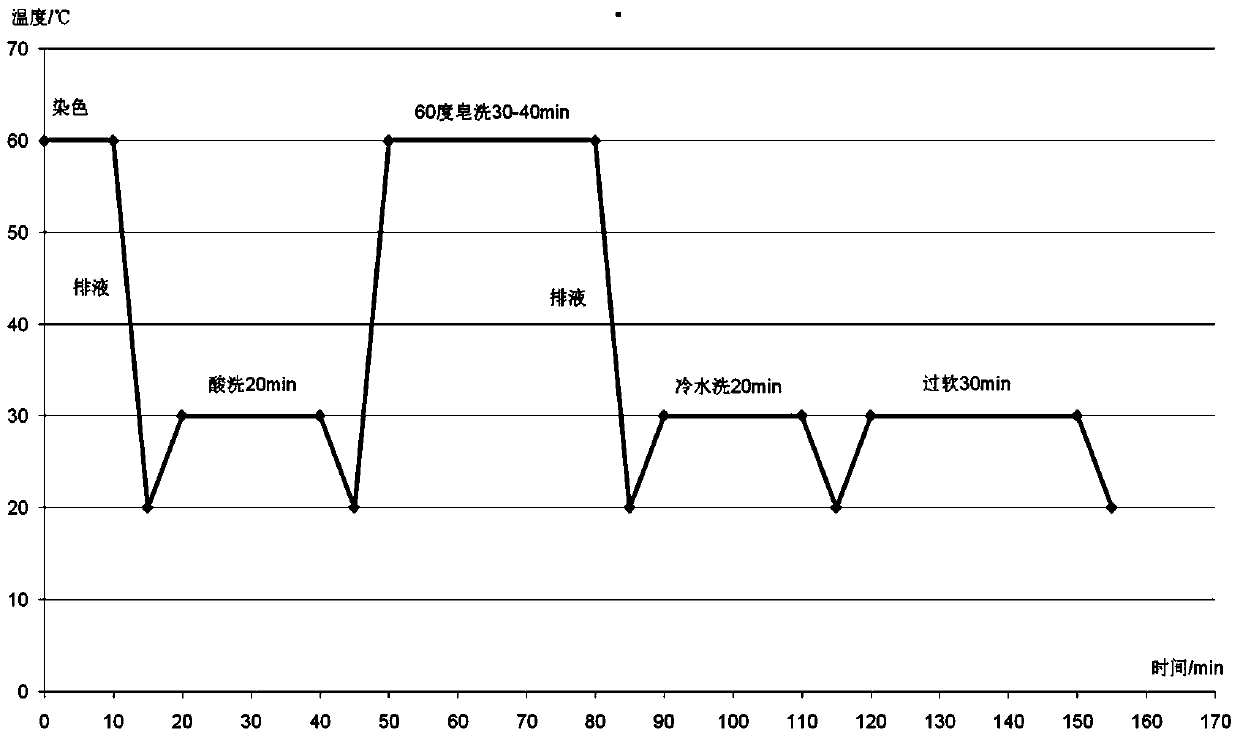

[0025] Such as figure 1 and figure 2 , processes such as dyeing, draining, cold water washing, pickling, soaping, hot water washing and oversofting are all processes known to those skilled in the art, and light-colored fabrics are the general term for a class of color and luster fabrics known to those skilled in the art. In the present invention, the amount of soaping enzyme used in the soaping process flow is 0.5-1.0 g / L. Select a group of comparative data from Example 1, such as Table 1 and Table 2.

[0026] Table 1: Traditional craft

[0027]

[0028] Table 2: Process of the present invention

[0029]

Embodiment 2

[0031] Such as image 3 and Figure 4 , processes such as dyeing, draining, cold water washing, pickling, soaping, hot water washing and softening are all processes well known to those skilled in the art, and neutral-colored fabrics are the general term for a class of color and luster fabrics known to those skilled in the art. In the present invention, the amount of soaping enzyme used in the soaping process flow is 1.0 g / L. A group of comparative data is selected from Example 2, as shown in Table 3 and Table 4.

[0032] Table 3: Traditional craft

[0033]

[0034] Table 4: Process of the present invention

[0035]

Embodiment 3

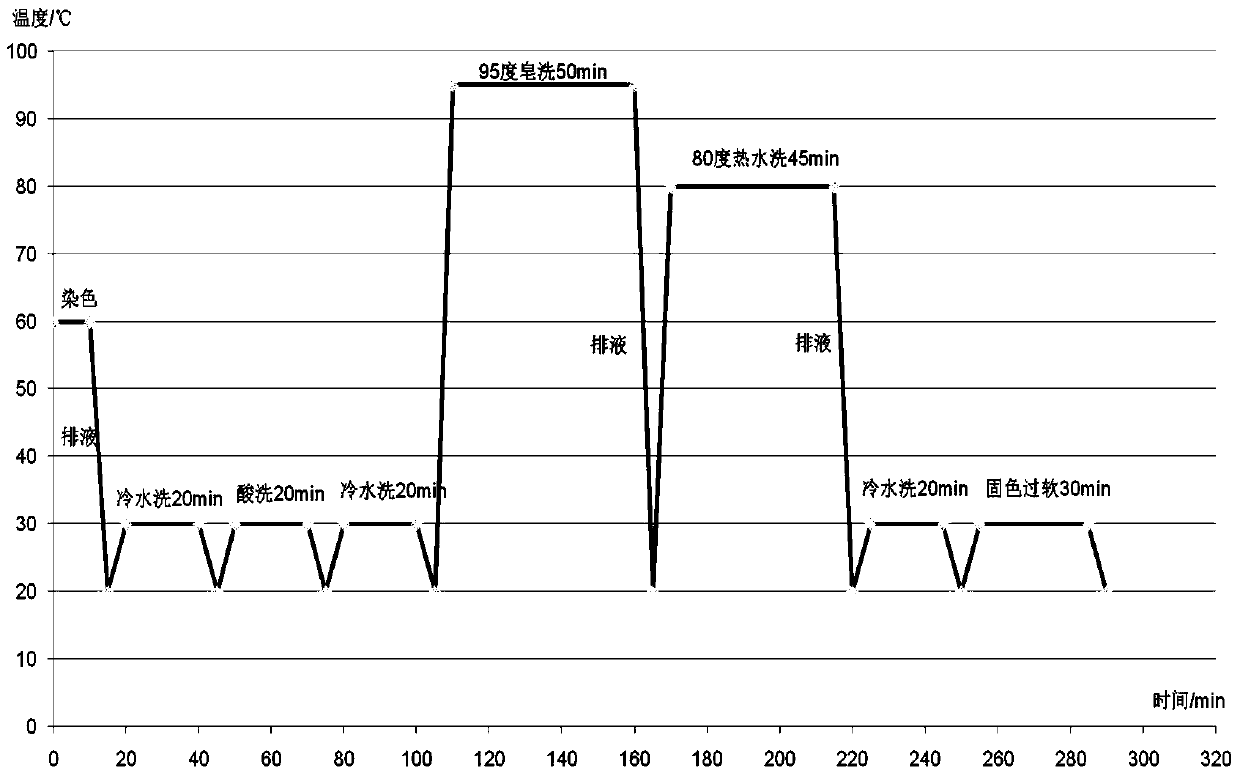

[0037] Such as Figure 5 and Figure 6 , processes such as dyeing, draining, cold water washing, pickling, soaping, hot water washing and softening are all processes known to those skilled in the art, and dark fabrics are the general term for a class of color and luster fabrics known to those skilled in the art. In the present invention, the amount of soaping enzyme used in the soaping process flow is 1.0 g / L. A group of comparative data is selected from Example 3, as shown in Table 5 and Table 6.

[0038] Table 5: Traditional craft

[0039]

[0040] Table 6: Process of the present invention

[0041]

[0042] In the above-mentioned embodiments 1-3, the data is unified as follows:

[0043] 1. Each unit price: water is 5.9 yuan per ton, electricity is 0.8 yuan per kWh, and steam is 181 yuan per ton.

[0044] 2. Additives: acid 4 yuan per kilogram, ordinary soaping agent 6 yuan, neutral enzyme 36 yuan per kilogram.

[0045] The fabrics after soaping in the above examp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com