A combined process for treating heavy metal complexing waste water

A combined process and heavy metal technology, which is applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, water pollutants, etc., can solve the problems that the new process is difficult to take into account the economic and environmental friendliness, and the treatment effect is poor. , to achieve the effect of high utilization rate, high utilization rate, and reduction of TOC and COD values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

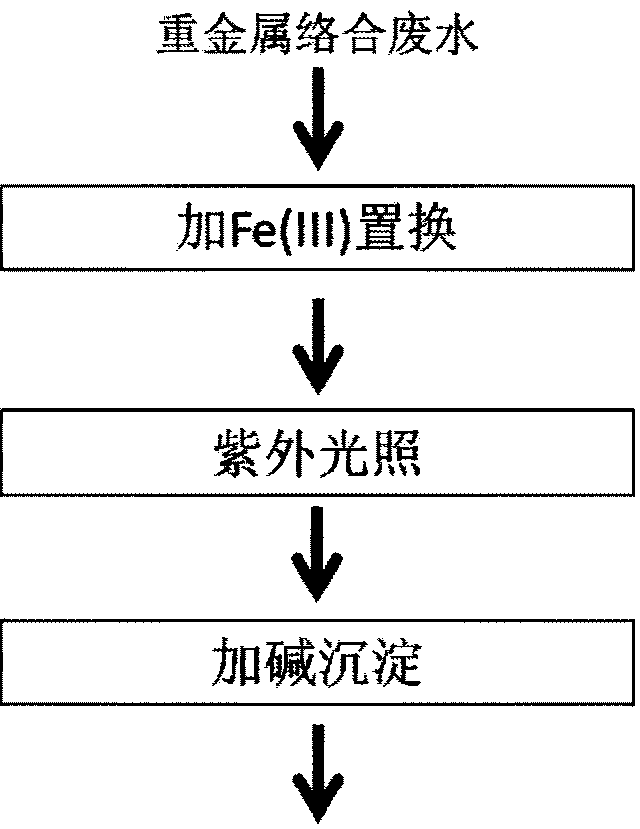

[0031] combine figure 1 , the copper concentration in the solution to be treated is 19.6mg / L, and contains excess citric acid.

[0032] Adopt a kind of combined process of processing heavy metal complex wastewater of the present invention to carry out wastewater treatment, its steps are:

[0033] Add ferric chloride according to the iron-copper molar ratio of 5:1, after mixing for 5 minutes, use a light intensity of 6mW / cm 2 Irradiate with a medium-pressure mercury lamp for 6 minutes, add calcium hydroxide to adjust the pH of the water to 9-10, and let it settle.

[0034] The remaining copper concentration in the final water body is about 0.4mg / L, the removal rate is about 98%, and the total organic carbon removal rate in water is 30-40%.

Embodiment 2

[0036] The copper concentration in the solution to be treated is 19.2 mg / L, and contains a slight excess of tartaric acid.

[0037] Adopt a kind of combined process of processing heavy metal complex wastewater of the present invention to carry out wastewater treatment, its steps are:

[0038] Add iron sulfate according to the iron-copper molar ratio of 6:1, after mixing for 10 minutes, use a light intensity of 6mW / cm 2 Irradiate with a medium-pressure mercury lamp for 8 minutes, add calcium oxide to adjust the pH of the water to 9-10, and let it settle.

[0039] The remaining copper concentration in the final water body is about 0.4mg / L, the removal rate is about 97.9%, and the total organic carbon removal rate in water is about 50%.

Embodiment 3

[0041] The copper concentration in the solution to be treated is 19.2mg / L, and contains slightly excess nitrilotriacetic acid.

[0042] Adopt a kind of combined process of processing heavy metal complex wastewater of the present invention to carry out wastewater treatment, its steps are:

[0043] Add ferric nitrate according to the iron-copper molar ratio of 6:1, mix for 10 minutes, and use a light intensity of 6mW / cm 2 Irradiate with a medium-pressure mercury lamp for 10 minutes, add sodium hydroxide to adjust the pH of the water to 9-10, and let it settle.

[0044] The remaining copper concentration in the final water body is about 0.7mg / L, the removal rate is about 96.4%, and the total organic carbon removal rate in water is about 30%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com