Non-disk cavity semiconductor laser with wavelength choice grating

A wavelength selection, semiconductor technology, applied in the field of microcavity lasers, can solve the problems of information distortion, low detection efficiency, logic errors, etc., and achieve the effect of high side mode suppression ratio and narrow spectral line width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

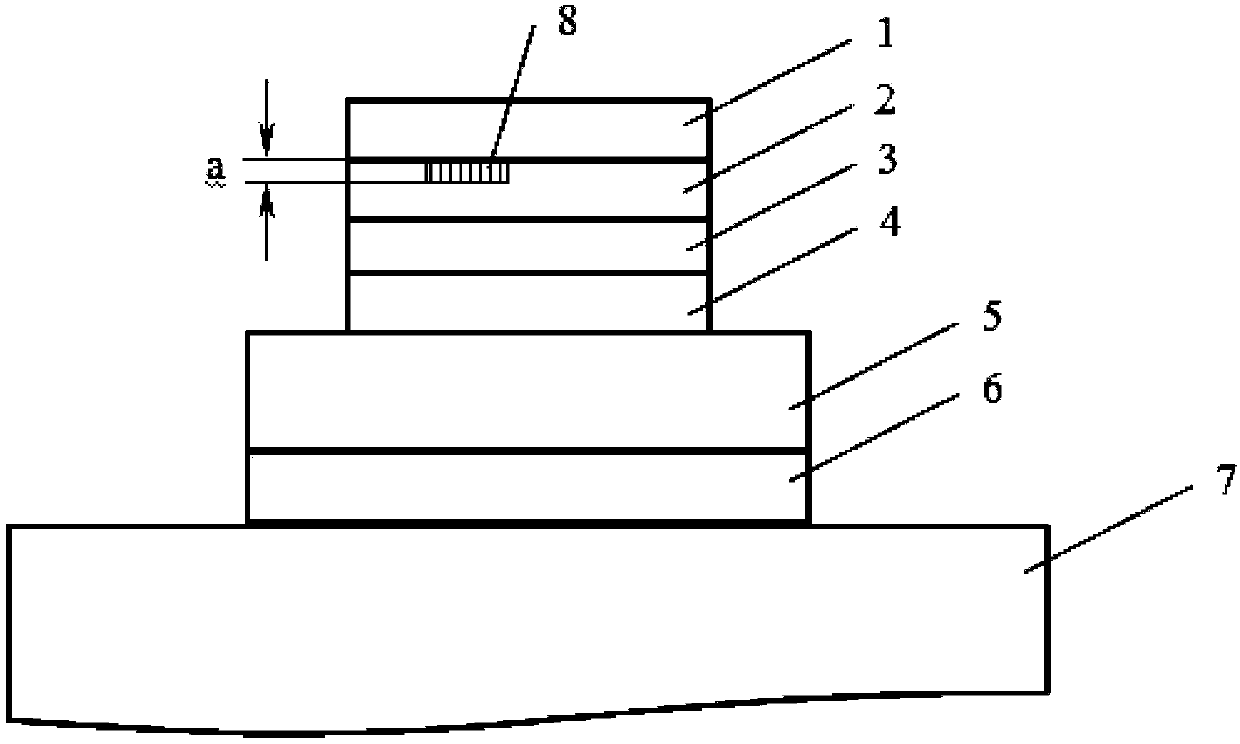

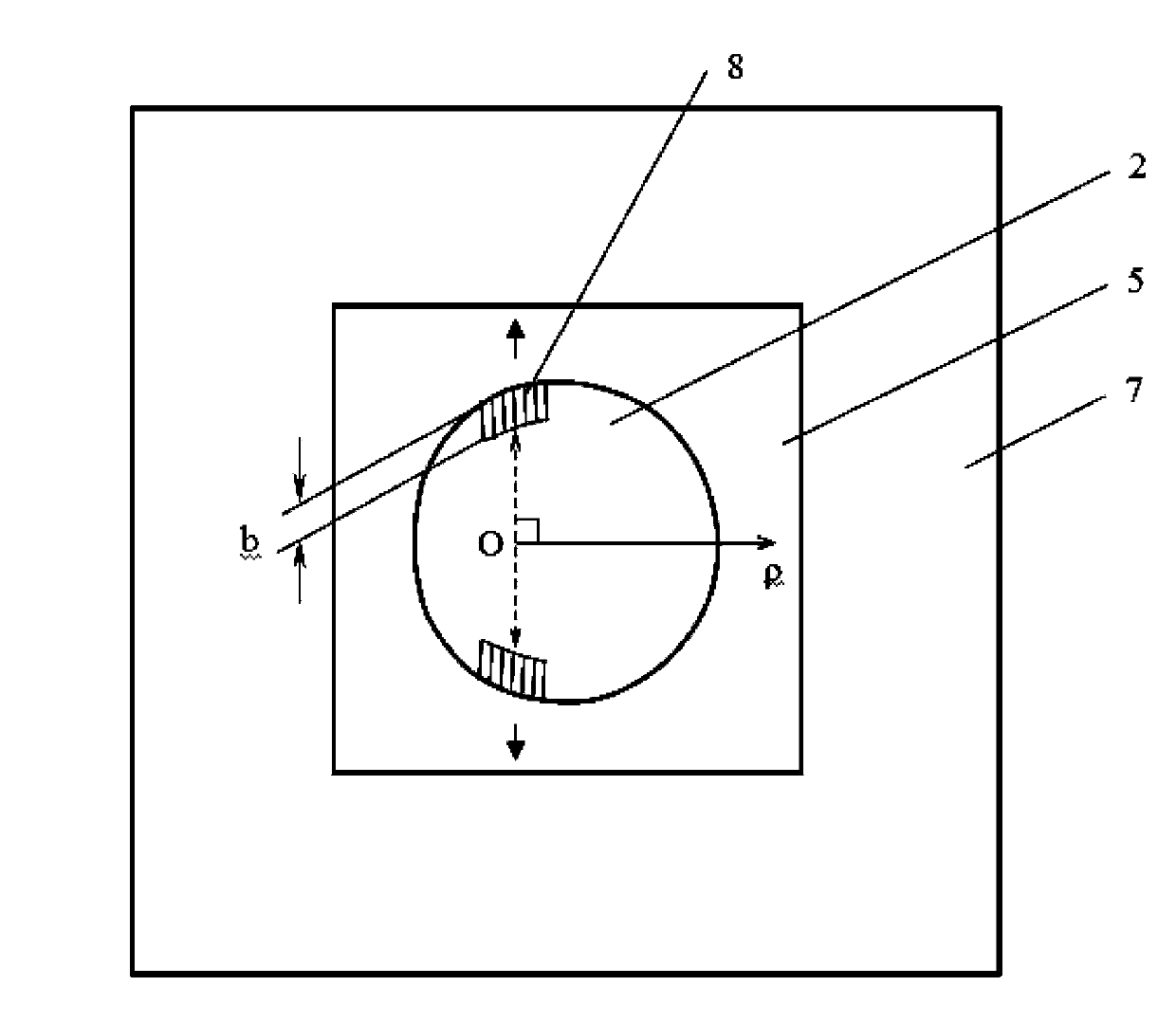

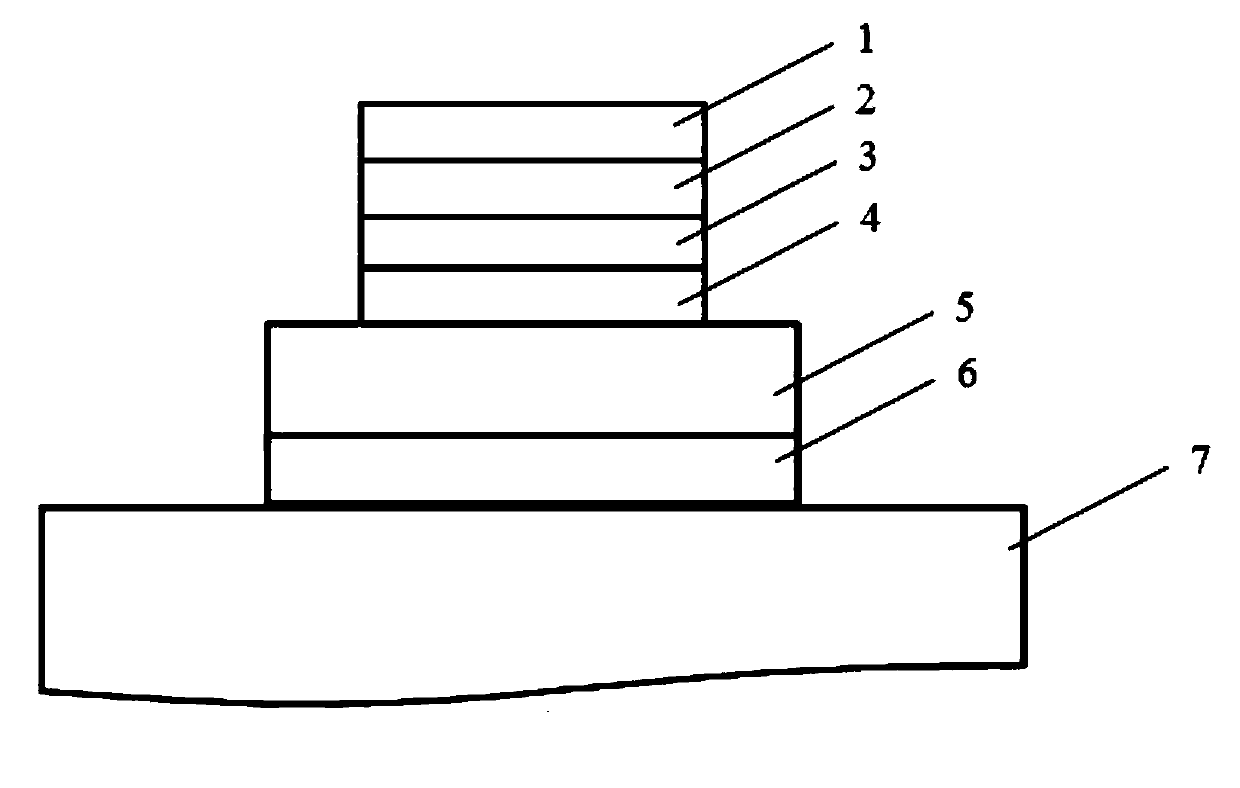

[0011] Such as figure 2 , image 3 As shown, the non-disc cavity semiconductor laser with wavelength selection grating of the present invention is an upper electrode 1, an upper waveguide layer 2, an active gain region 3, a lower waveguide layer 4, a substrate 5, and a lower electrode from top to bottom. 6. Heat sink 7. Both the upper electrode 1 and the lower electrode 6 are gold electrodes. Both the upper waveguide layer 2 and the lower waveguide layer are InGaAsP layers. The active gain region 3 is an InGaAs / InAlAs quantum well cascaded structure. The material of the substrate 5 is InP. The heat sink 7 is a copper plate. The lower electrode 6 is directly welded on the heat sink 7 by solder. Alternatively, an AlN (aluminum nitride) heat sink is welded between the lower electrode 6 and the heat sink 7 . The upper waveguide layer 2, the active gain region 3, and the lower waveguide layer 4 have outer boundaries of the same shape, and the outer boundary curve is type ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com