Method for restoring state of semiconductor equipment software after restart

A technology of software restart and recovery methods, applied in the direction of instruments, computer control, simulators, etc., can solve the problems of inability to guarantee, lack of data recording and data recovery technology, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

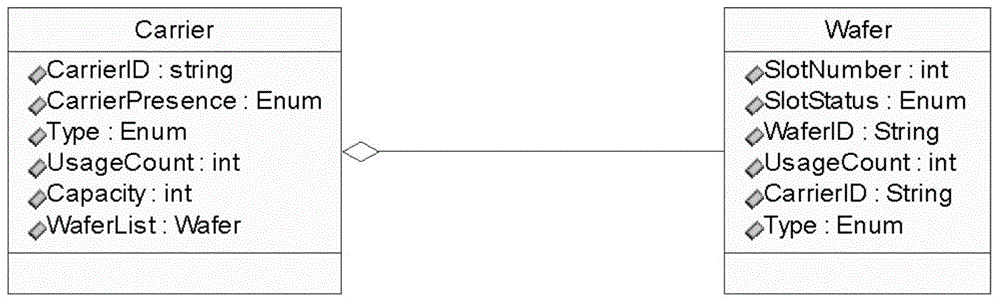

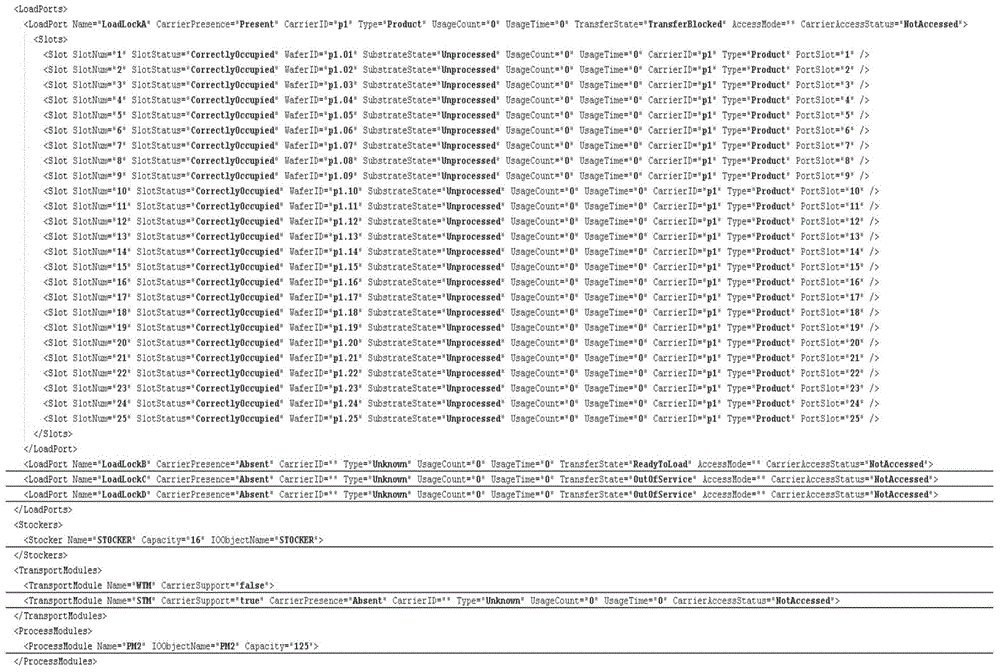

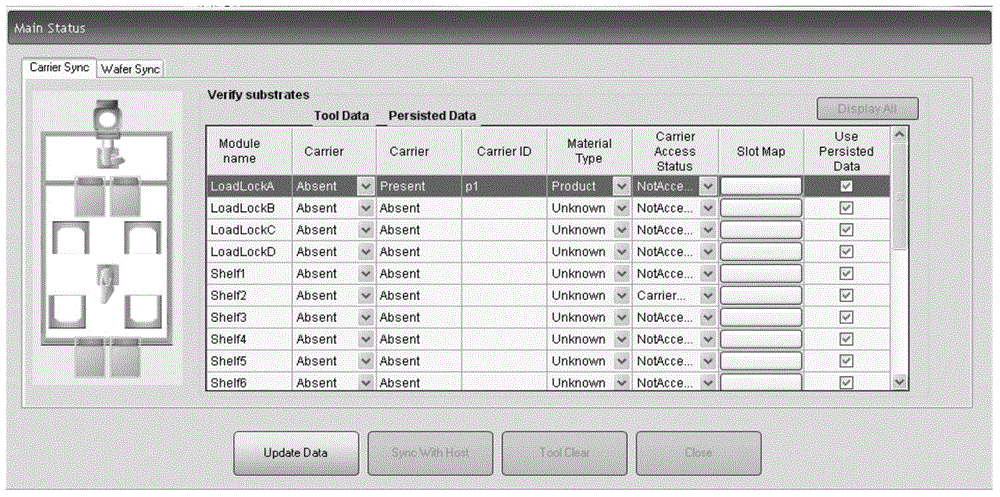

[0023] It should be noted that the method for restoring the state of the semiconductor device software after restarting according to the present invention is suitable for a system in which the semiconductor device includes a technology storage unit and a control unit. The technology storage unit and the control unit in the above-mentioned system can be realized by hardware, software or a combination of software and hardware. In this embodiment, the above-mentioned unit is composed of a host computer + a lower computer architecture; wherein, the lower computer is a programmable logic controller (Programmable Logic Device, referred to as PLD). The technical solutions in the embodiments of the present invention can be summarized as follows: that is, the method specifically includes the following steps:

[0024] Step S1: According to the attribute hierarchy structure of the actual process module of the equipment recorded in the technology storage unit, configure the record file co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com