Camera module and making method thereof

A technology of a camera module and a manufacturing method, applied in the field of camera modules and their manufacturing, can solve the problems of increasing the size of the flexible circuit, reducing the volume of the camera module, and reducing the cost of the camera module, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

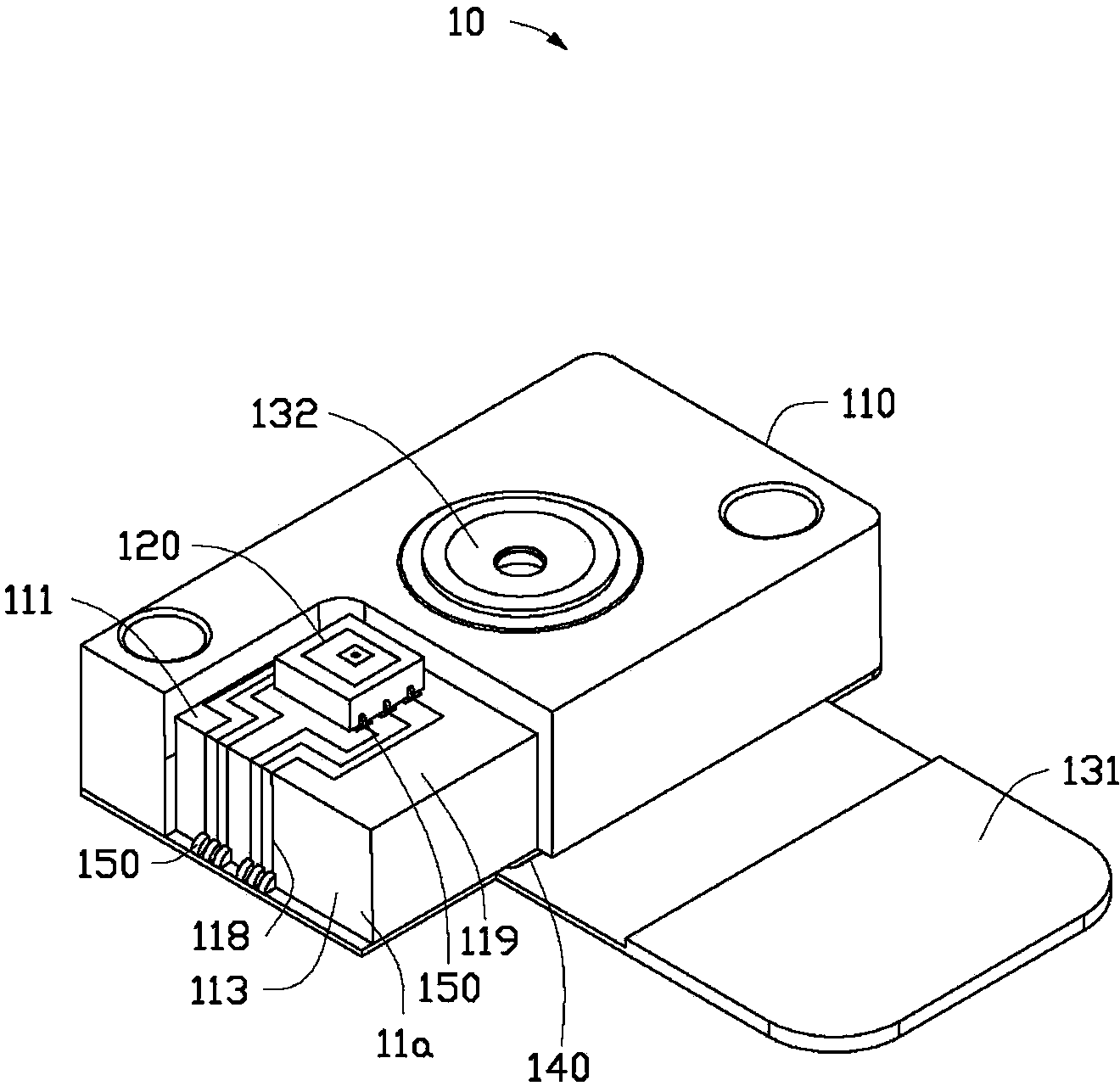

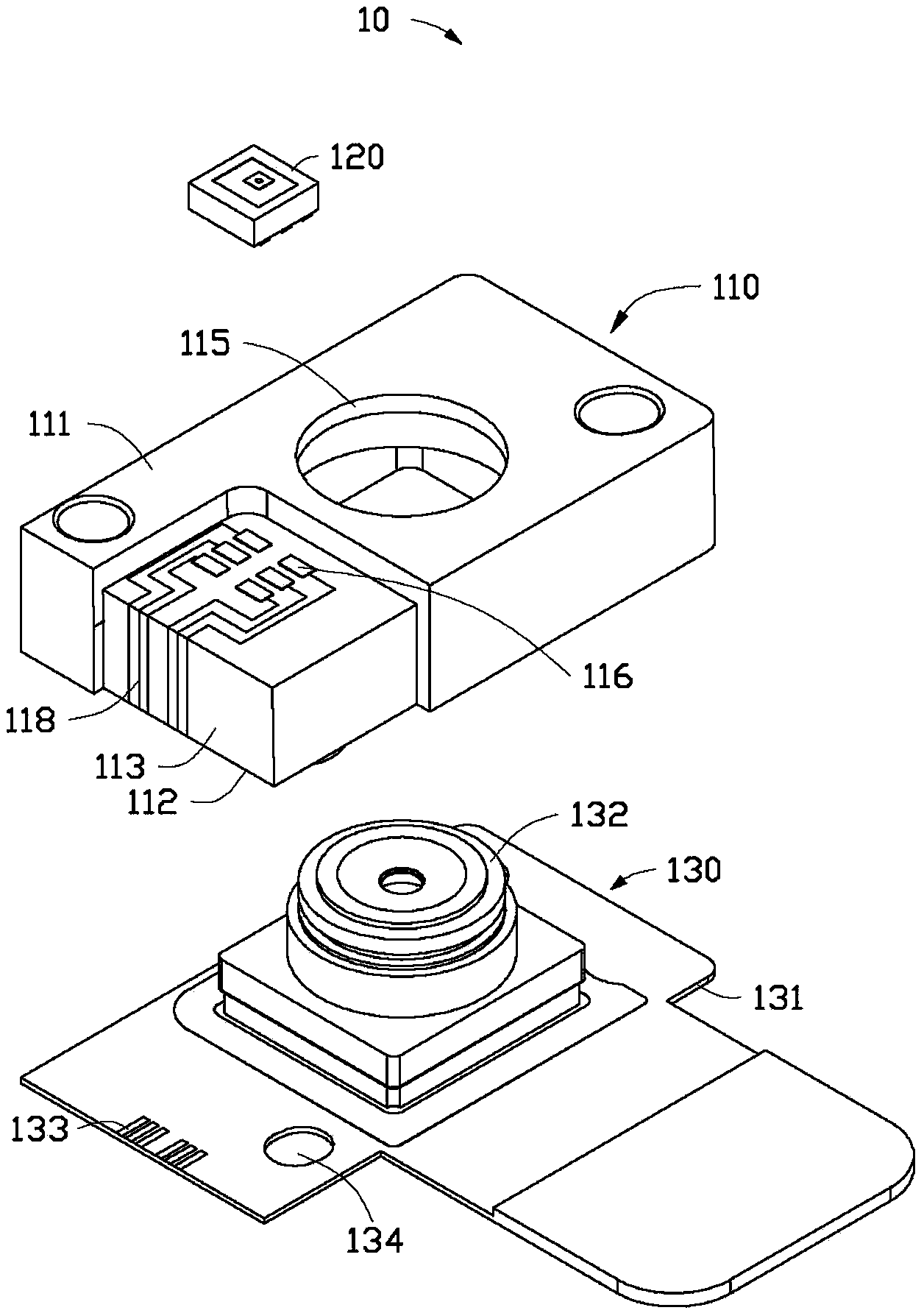

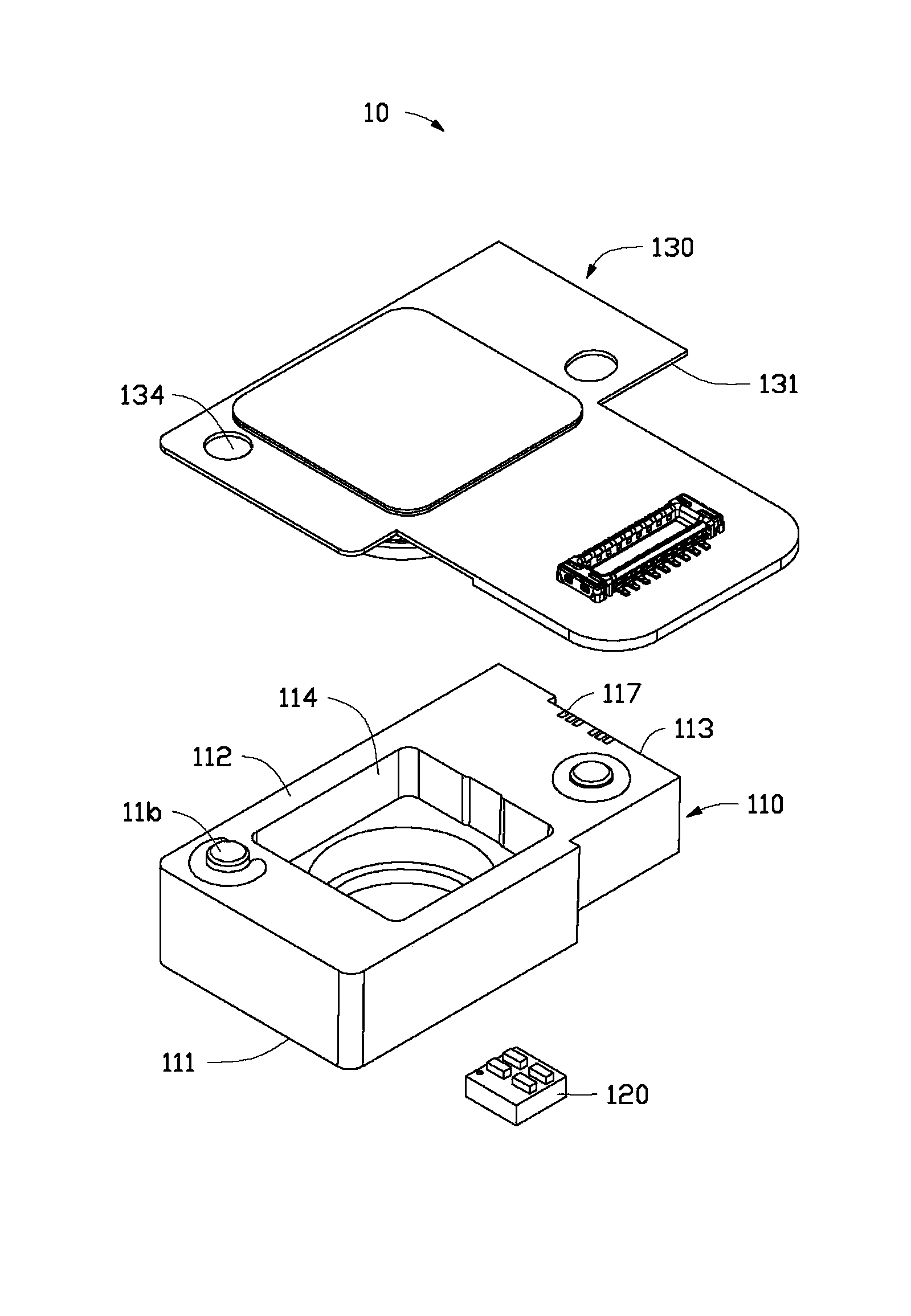

[0026] see Figure 1-3 , the camera module 10 of the preferred embodiment of the present invention includes a casing 110 , an ambient light sensor 120 and a lens module 130 . The housing 110 includes a top surface 111 , a bottom surface 112 opposite to the top surface 111 , and a side surface 113 connecting the top surface 111 and the bottom surface 112 . The housing 110 defines a receiving groove 114 on the bottom surface 112 and defines a through hole 115 communicating with the receiving groove 114 on the top surface 111 . The shell 110 forms a solder seat 116 on the top surface 111 near the side 113 by laser directing structure (LDS), forms a first connector 117 on the bottom 112 near the side 113, and A circuit 118 connecting the solder socket 116 and the first connector 117 is formed on the side surface 113 . The ambient light sensor 120 is welded on the socket 116 . The lens module 130 includes a circuit board 131 (such as a flexible circuit board) attached to the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com