Accelerated loading abrasion device for pavement

A technology of accelerating loading and loading device, applied in the direction of testing wear resistance, etc., can solve the problems of low speed, not meeting the test target, unable to reliably evaluate and predict the function of the road surface, so as to reduce the time required for the test and shorten the test. effect of time required

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions provided by the present invention will be described in detail below in conjunction with specific examples. It should be understood that the following specific embodiments are only used to illustrate the present invention and are not intended to limit the scope of the present invention.

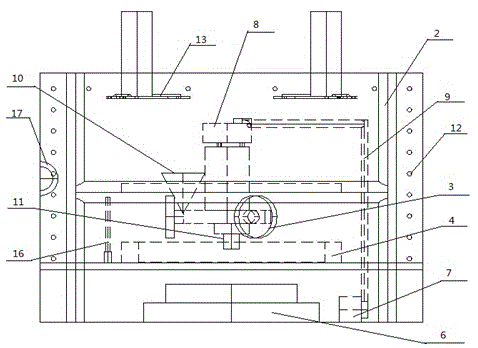

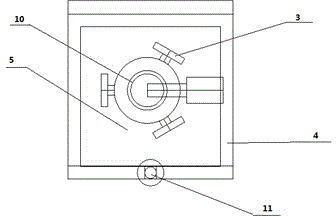

[0033] Such as Figure 1 to Figure 5 A pavement accelerated loading wear device shown includes a case 1, a bracket 2, a loaded tire 3, a specimen tray 4, a pavement specimen 5, an oil pressure self-controlled loading device 6, a power system for loading tires, and an emery sander 10. Water film thickness control valve 11, temperature adjustment system, and an instrument control panel 14 is also arranged on the casing 1.

[0034] The casing 1 is an airtight casing, and the inside of the casing 1 is provided with a bracket 2. The function of the bracket 2 is mainly to support the entire structure of the instrument, and at the same time provide a reverse force for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com