Cylinder head cover of diesel engine

A technology for cylinder head covers and diesel engines, which is applied to mechanical equipment, engine components, machines/engines, etc. It can solve the problems of easy oil leakage, poor sealing of mouth edges, and difficult processing of double-layer edges. The effect of preventing spillage and enhancing the sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention is described in detail below in conjunction with accompanying drawing:

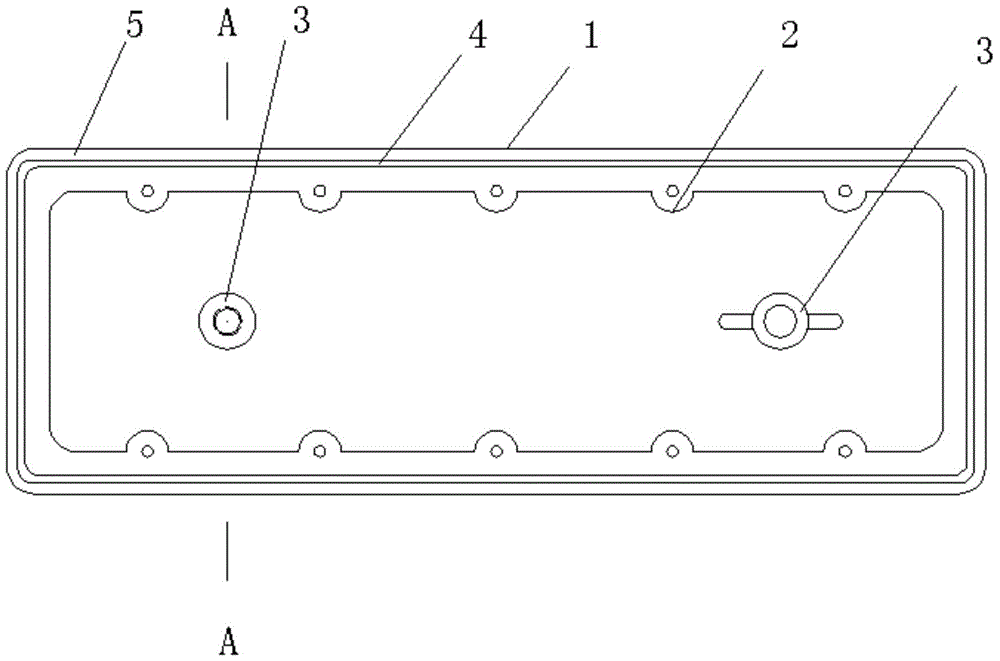

[0010] Example: as figure 1 As shown, in the diesel engine cylinder head cover of the present invention, the side plates 2 of the cover body 1 adopt corrugated side plates, which help to increase the surface heat dissipation area of the diesel engine cylinder head cover, and achieve the effect of enhancing heat dissipation; at the same time, the corrugated side plates 2 The corrugated form helps to absorb noise and achieve the effect of noise reduction.

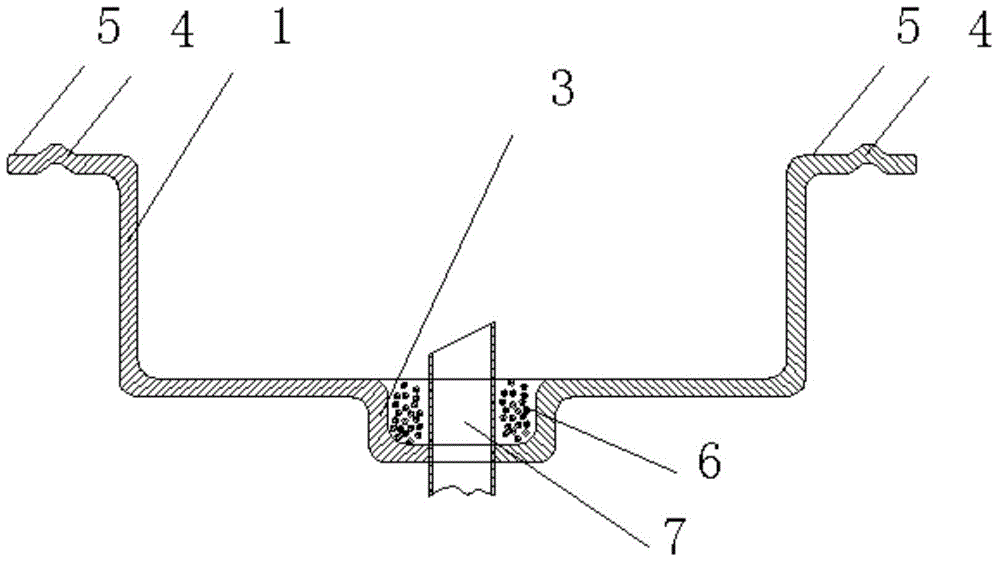

[0011] Such as figure 2 As shown, the diesel engine cylinder head cover of the present invention has one or two rings of sealing ribs 4 on the connecting table 5 on the edge of the opening end of the cover body 1. When the sealing ring is installed, the sealing ribs 4 are placed against the sealing ring of the cylinder head. On, the sealing performance of the cylinder head is enhanced. Such as figure 2 As shown, the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com