Flexible composite tubing string lifting equipment

A technology of composite tubing and equipment, applied in drilling equipment, drill pipe, casing and other directions, can solve the problems of difficult maintenance, inability to open, complex structure, etc., and achieve the effect of facilitating well site operations and avoiding wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

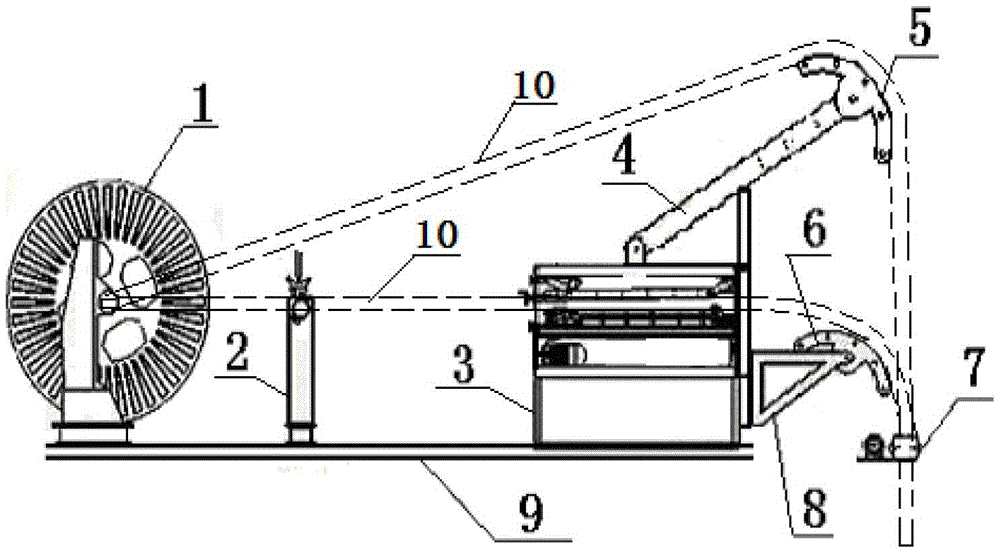

[0022] refer to Figures 1 to 7 Embodiments of the present invention are further described:

[0023] The present invention includes a take-up and release mechanism 1, a cable arrangement mechanism 2, a traction mechanism 3, a pole 4, an upper gooseneck pulley 5, a lower gooseneck pulley 6, a wellhead straightening mechanism 7, a triangular bracket 8 and a base 9:

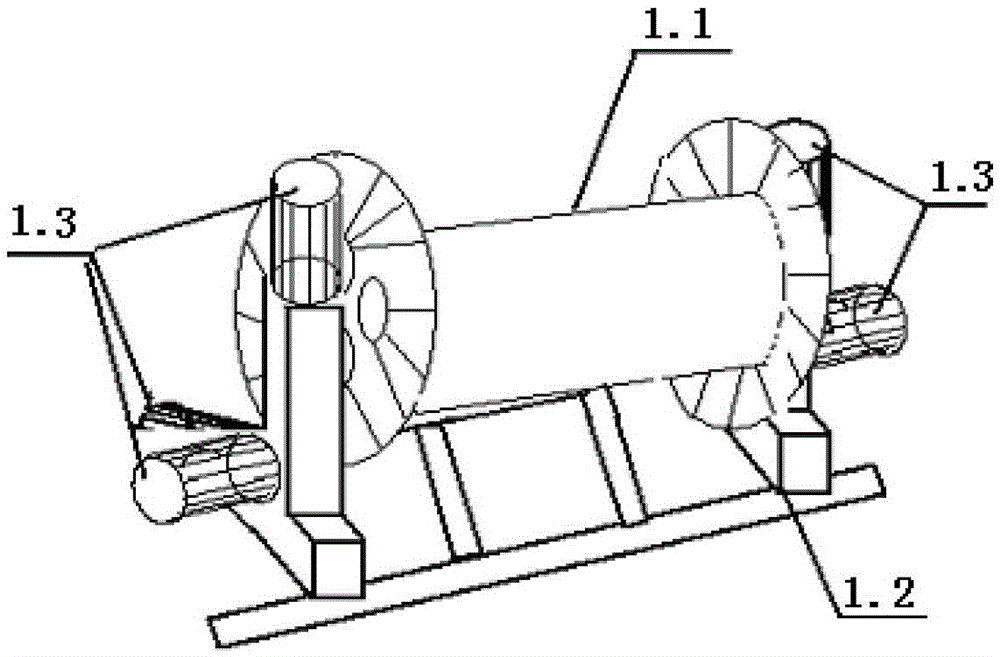

[0024] The take-up and pay-off reel 1.1 of the take-up and pay-off mechanism 1 is fixed on the take-up and pay-off support 1.2, and the two ends of the support 1.2 are provided with a take-up and pay-off driving device 1.3 for controlling the speed and movement direction of the take-up and pay-off reel 1.1.

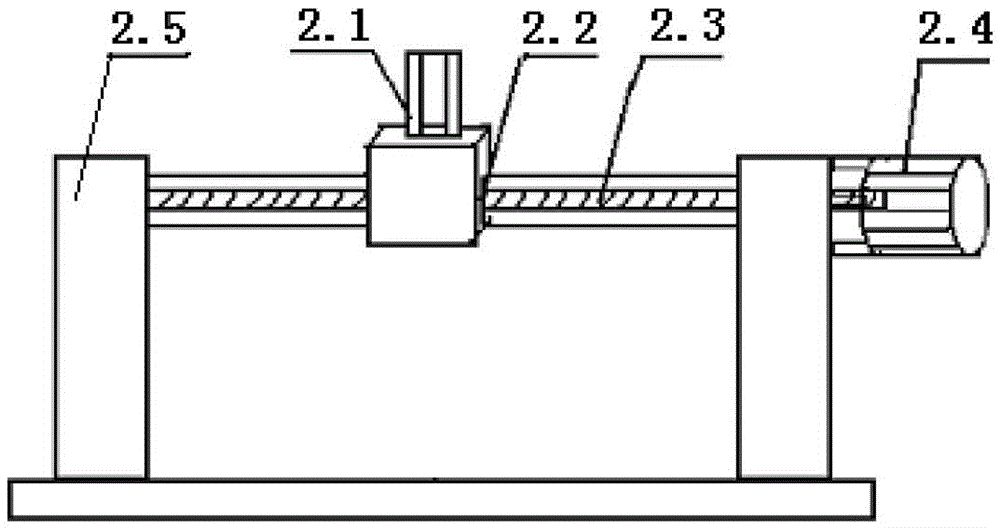

[0025] The lead screw 2.3 of the cable arrangement mechanism 2 is set on the cable support 2.5, and one end of the lead screw 2.3 is connected to the cable drive device 2.4 for controlling its rotation; switch 2.2. The cable arranging drive device 2.4 and the limit switch 2.2 drive the cable arranging instrum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com