Construction and application of C.glutamicum subspecies lactofermentum with high L-methionine yield

A Corynebacterium glutamicum and methionine technology, applied in the field of bioengineering, can solve the problems of no industrial application of methionine, unfavorable food safety fermentation, unfavorable strain metabolic engineering transformation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

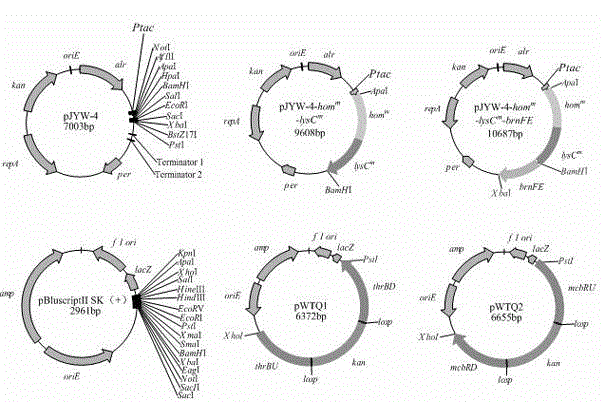

[0019] Embodiment 1, the construction of recombinant Corynebacterium glutamicum

[0020] In this example, plasmids for knocking out and expressing related genes in Corynebacterium glutamicum were first constructed, and then the constructed plasmids were transformed into corresponding Corynebacterium glutamicum respectively, so as to realize the expression of related genes. knockout and overexpression.

[0021] 1.1 Gene encoding homoserine kinase thr B and the gene encoding the repressor protein McbR wxya Construction of knockout plasmids

[0022] 1.1.1 Knockout the upstream and downstream homology arms mcbRU, mcbRD, thrBU, thrBD and loxp - can - Amplification of loxp fragments

[0023] In this example, primers for amplification were first designed, and the genome and plasmids used for amplifying the template were extracted, and then relevant gene fragments were amplified by PCR. details as follows:

[0024] According to Genebank report thr B , wxya For the gene sequ...

Embodiment 2

[0104] Embodiment 2, recombinant Corynebacterium glutamicum shake flask level production methionine

[0105] The medium formula used in this example is as follows:

[0106] Seed medium: 25 g / L glucose, 20 g / L corn steep liquor, 1 g / L KH 2 PO 4 , 0.5 g / L MgSO 4 , 1.25 g / L urea.

[0107] Fermentation medium: 100 g / L glucose, 20 g / L corn steep liquor, 20 g / L (NH 4 ) 2 SO 4 , 1 g / L KH 2 PO 4 , 0.5 g / L MgSO 4 , 0.01 g / L MnSO 4 , 0.01 g / L FeSO 4 , 1 mg / L VB1, 6 mg / L VB6, 0.1 mg / L VH, 0.2 g / L VB12.

[0108] Pick activated single colony in 30mL / 250mL seed medium, culture at 30°C, 200 rpm for 18 h. Then press initial OD 562 1 was transferred to 50mL / 500mL fermentation medium, wherein 20 g / L calcium carbonate was added to the fermentation medium to balance the pH. Incubate at 30°C, 200 rpm for 72 h. Sampling was carried out to determine the relevant amino acid production.

[0109] In the present embodiment, the amino acid content of the fermented liquid adopts HPLC to me...

Embodiment 3

[0112] Example 3, the best mutant strain WTQ102 / pJYW-4- hom m - lysC m - brnFE Production of methionine at fermenter level

[0113] The seed medium and fermentation medium used in this example were the same as those in Example 2.

[0114] Pick activated single colony in 50mL / 500mL seed medium, culture at 30°C, 200 rpm for 18 h. Then press initial OD 562Transfer to 1.2L / 3L fermenter for 1. Adjust the pH to 7.0 by feeding ammonia water, control the dissolved oxygen to 30% by correlating the stirring speed and aeration rate, and control the residual sugar above 20g / L by adding 50% glucose. Samples were taken every 4 h to determine the bacterial concentration, residual sugar and amino acid content. Wherein the amino acid detection method is exactly the same as that in Example 2. The test results showed that the methionine yield reached the highest level at 48 h of fermentation, and the highest yield was 3.1 g / L.

[0115] SEQ ID NO.1

[0116] According to genebank rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com