Liquid Crystal Aligning Agent And Forming Method Thereof, Liquid Crystal Alignment Film And Forming Method Thereof, Phase Difference Film And Manufacturing Method Thereof, And Liquid Crystal Display Device And Manufacturing Method Thereof

A technology of liquid crystal alignment agent and liquid crystal alignment film, which is applied in the directions of liquid crystal materials, chemical instruments and methods, instruments, etc., can solve the problems of insufficient yield of liquid crystal alignment film products, uneven printing, and product yield limit, etc. Excellent orientation and adhesion, excellent printability, and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0229] (1) Preparation of liquid crystal aligning agent

[0230] The polymer (PA-1) obtained in the synthesis example PA-1 is dissolved in a mixed solvent comprising N-methyl-2-pyrrolidone (NMP) and butyl cellosolve (BC) (the solvent composition is NMP; BC = 50:50 (weight ratio)) to prepare a solution having a polymer concentration of 6.0% by weight. The liquid crystal aligning agent was obtained by filtering this solution with the filter of 1 micrometer of pore diameters.

[0231] (2) Evaluation of printability

[0232] The printability of the liquid crystal aligning agent prepared above was evaluated.

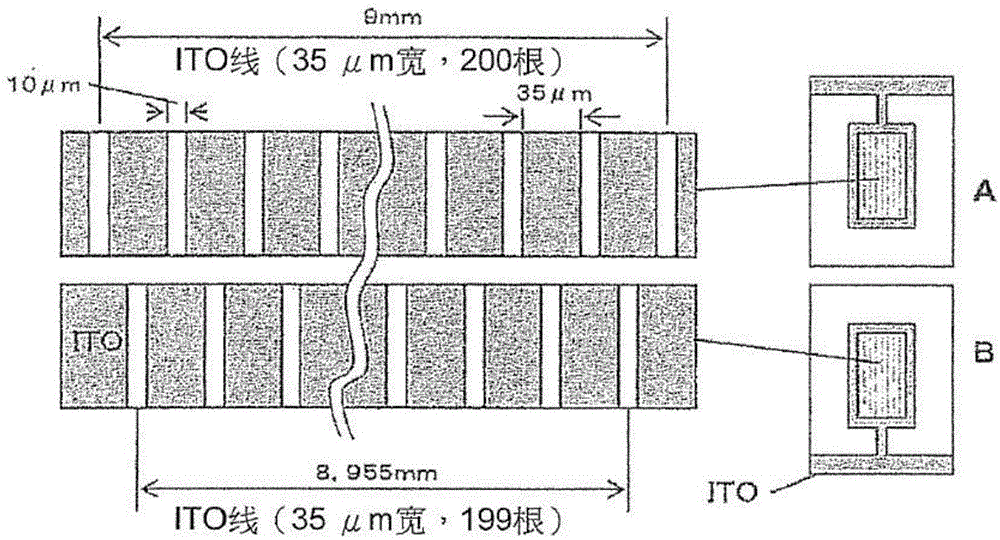

[0233] First, using an offset-type liquid crystal alignment film printer (manufactured by Nippon Photo Printing Co., Ltd.), the liquid crystal alignment agent was coated on the transparent electrode surface of a glass substrate with a transparent electrode comprising an ITO film, and the After heating (pre-baking) on a hot plate for 1 minute to remove the solvent, heat (...

Embodiment 2~ Embodiment 6 and comparative example 1

[0257] Except having made the kind and quantity of the polymer used for preparing a liquid crystal aligning agent into Table 2, respectively, the liquid crystal aligning agent was prepared similarly to the said Example 1, and the liquid crystal display element was manufactured and evaluated.

[0258] The evaluation results are shown in Table 2.

[0259] [Table 2] Preparation and evaluation of liquid crystal aligning agent

[0260]

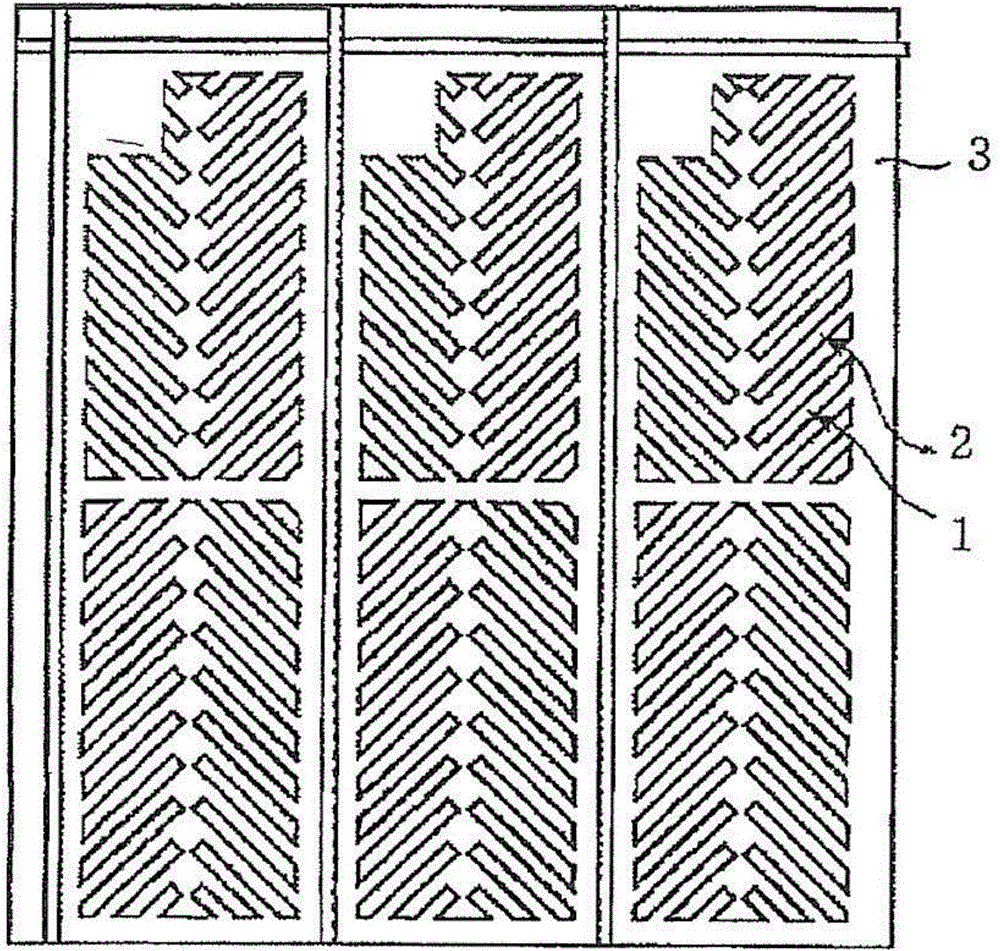

[0261] Furthermore, in addition to changing the patterns of the ITO electrodes on the glass substrate as figure 2 as well as image 3 Except for the herringbone electrode pattern shown, the liquid crystal display element was manufactured similarly to the said Example 1 using the liquid crystal aligning agent in said Example 1 - Example 6, respectively, and it evaluated. Also in this case, it was confirmed that the same effects as those of Examples 1 to 6 were exhibited.

Embodiment 7

[0263] (1) Preparation of liquid crystal aligning agent

[0264] The polymer (PA-6) obtained in the synthesis example PA-6 was dissolved in a mixture containing N-methyl-2-pyrrolidone (NMP), γ-butyrolactone (GBL) and butyl cellosolve (BC). In a solvent (solvent composition: NMP:GBL:BC=40:40:20 (weight ratio)), a solution having a polymer concentration of 3.0% by weight was prepared. The liquid crystal aligning agent was obtained by filtering this solution with the filter of 1 micrometer of pore diameters.

[0265] (2) Manufacture of FFS type liquid crystal display element 1

[0266] Made as Figure 4 The FFS type liquid crystal display element shown.

[0267] Firstly, a glass substrate having an electrode pair on which a bottom electrode without a pattern, a silicon nitride film as an insulating layer, and an upper electrode patterned into a comb-like shape is sequentially formed on one side, and the opposite side without an electrode The glass substrate was used as a pair...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com