A kind of hpn/tlcp/hnts composite material and preparation method thereof

A composite material and raw material technology, applied in the field of engineering plastics, can solve problems such as poor processing performance, poor fluidity of high-temperature-resistant nylon, and mechanical properties that cannot meet industrial requirements, and achieve good self-dispersion, difficult agglomeration, and good economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

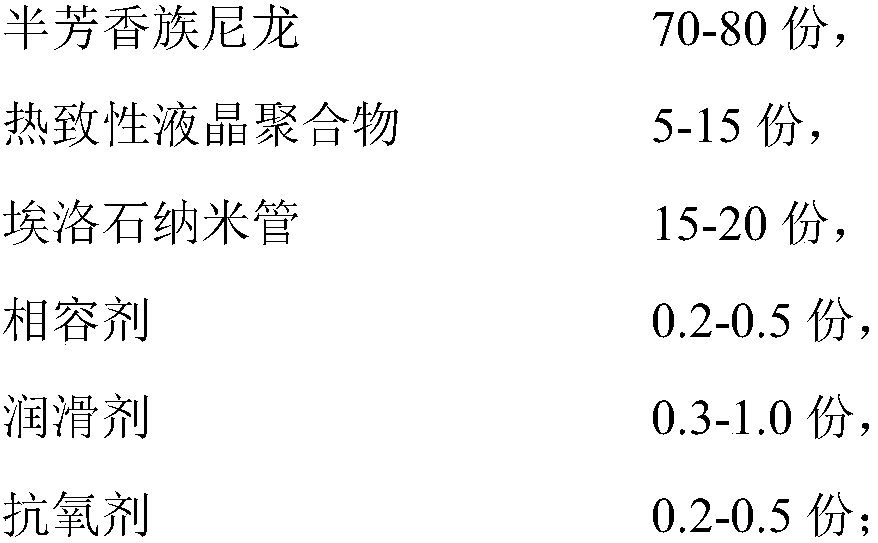

Embodiment 1

[0038] A HPN / TLCP / HNTs nanotube composite material, made of the following raw materials in parts by weight: 70 parts of semi-aromatic nylon PA10T, 5 parts of liquid crystal polymer 5130L, 10 parts of HNTs nanotubes, 0.5 parts of maleic anhydride, stearic acid 1 part of calcium lubricant, 0.5 part of antioxidant, wherein the antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; its preparation method is:

[0039] (1) Dry high-temperature-resistant nylon resin, liquid crystal polymer and halloysite nanotubes at 120°C, 140°C and 90°C for 10 hours, respectively;

[0040] (2) Use a high-speed mixer to mix the lubricant, antioxidant and compatibilizer at high speed, and then put it in a drying oven for drying. The drying temperature is 90°C and the drying time is 3 hours;

[0041] (3) Put the raw materials processed in step (1) (2) into the high-speed mixer and mix them uniformly for 5 minutes;

[0042] (4) Put the mixed raw materials in ...

Embodiment 2

[0044] A HPN / TLCP / HNTs nanotube composite material, made of the following raw materials in parts by weight: 75 parts of semi-aromatic nylon PA10T, 10 parts of liquid crystal polymer 5130L, 15 parts of HNTs nanotubes, 0.5 parts of maleic anhydride, stearic acid 1 part of calcium lubricant, 0.5 part of antioxidant, wherein the antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; its preparation method is:

[0045] (1) Dry high-temperature-resistant nylon resin, liquid crystal polymer and halloysite nanotubes at 130°C, 150°C and 100°C for 8 hours, respectively;

[0046] (2) Use a high-speed mixer to mix the lubricant, antioxidant and compatibilizer at high speed, and then put it in a drying oven for drying. The drying temperature is 100°C and the drying time is 1 hour;

[0047] (3) Put the raw materials processed in step (1) (2) into the high-speed mixer and mix them uniformly for 8 minutes;

[0048] (4) Put the mixed raw materials in...

Embodiment 3

[0050] A HPN / TLCP / HNTs nanotube composite material, made of the following raw materials in parts by weight: 80 parts of semi-aromatic nylon PA10T, 15 parts of liquid crystal polymer 5130L, 20 parts of HNTs nanotubes, 0.5 parts of maleic anhydride, stearic acid 1 part of calcium lubricant, 0.5 part of antioxidant, wherein the antioxidant is tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester; its preparation method is:

[0051] (1) Dry high-temperature-resistant nylon resin, liquid crystal polymer and halloysite nanotubes at 125°C, 145°C and 95°C for 9 hours, respectively;

[0052] (2) Use a high-speed mixer to mix the lubricant, antioxidant and compatibilizer at high speed, and then put it in a drying oven for drying. The drying temperature is 95°C and the drying time is 2 hours;

[0053] (3) Put the raw materials processed in step (1) (2) into the high-speed mixer, and mix evenly for 10 minutes;

[0054] (4) Put the raw materials mixed in step (...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com