Amino molding plastic granulation apparatus and process based on apparatus

A technology of amino molding compound and granulation equipment, which is applied in the technical field of amino molding compound granulation, can solve the problems of unstable physical properties, many chemical volatiles, volatile fluidity, etc., and achieves protection of physical properties, high strength, The effect of extending the shelf life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to have a further understanding and understanding of the structural features of the present invention and the achieved effects, the preferred embodiments and accompanying drawings will be used for a detailed description, as follows:

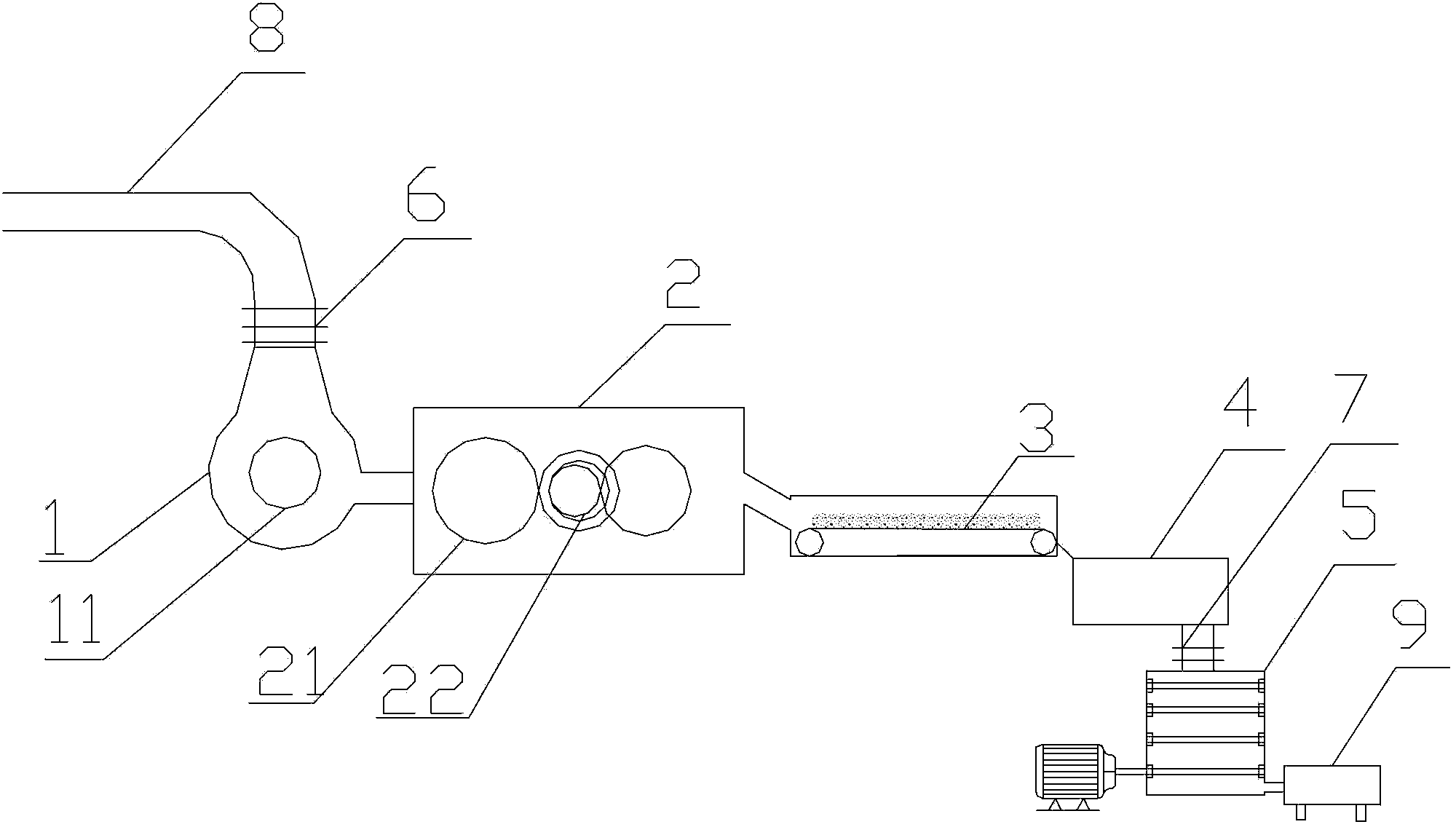

[0019] Such as figure 1 As shown, the equipment for making amino molding compound granules in the present invention includes a screw extruder 1 for refining and extruding the amino molding compound into blocks, a roll machine 2 for further extruding the block amino molding compound into sheets, and cooling Equipment 4, crusher 5, feed valve 6 and discharge valve 7, feed valve 6 is fixedly arranged at the input port of screw extruder 1 in a sealed connection, and the output port of screw extruder 1 is directly connected to the roll The input port of the machine 2 is fixedly connected, the roll machine 2 includes a rolling wheel 21 and a roll core 22, the output port of the roll machine 2 is connected with the cooling device 4 throu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com