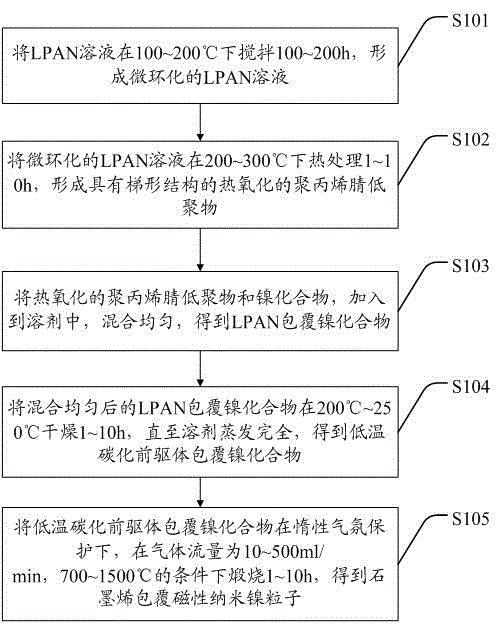

A kind of graphene-coated magnetic nano-nickel particles and preparation method thereof

A graphene-coated, magnetic nanotechnology, applied in the direction of the magnetism of inorganic materials, can solve the problems of easy oxidation of metal nanoparticles, low saturation magnetization, complex process, etc., and achieve high magnetic saturation value, good shape, and equipment technology. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

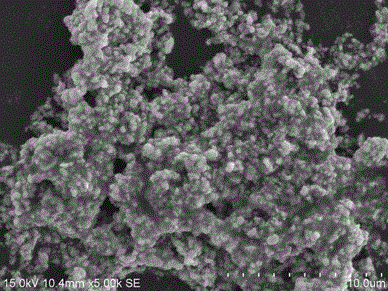

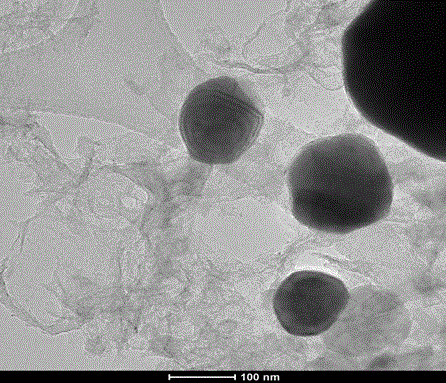

Embodiment 1

[0056] Stir 3g of LPAN solution (molecular weight 4000) at 120°C for 120h to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 250°C for 8h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 7.6g of nickel oxide, 20ml of solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 7:1, 500rad / min ball mill for 10h, after discharging, dry in an oven at 230°C for 3h to obtain the thermal oxidation precursor (That is, low temperature carbonization precursor coated nickel compound). Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 150ml / min, calcinate at 900°C for 4 hours, and cool to room temperature to obtain a graphene-coated nickel magnetic nanoparticle composite. The product structure is as follows: Figure 2a (SEM spectrum, scanning electron microscope spectrum), 2b (XRD spectrum, X-ray diff...

Embodiment 2

[0058] Stir 7.5g of LPAN solution (molecular weight 1600) at 100°C for 200h to form a microcyclized LPAN solution, heat-treat the microcyclized LPAN solution at 300°C for 1h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 3.17g nickel oxide, 30ml solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 7:1, 500rad / min ball mill for 10h, after discharging, dry in an oven at 230°C for 10h to get the pre-oxidized body. Put the thermal oxidation precursor in a porcelain boat, under the protection of an inert atmosphere, with a gas flow rate of 150ml / min, calcined at 1300°C for 4 hours, and cooled to room temperature to obtain a composite of graphene-coated nickel magnetic nanoparticles. The product structure is as follows: Figure 3a (SEM spectrum, scanning electron microscope spectrum), 3b (XRD spectrum, X-ray diffraction analysis spectrum).

Embodiment 3

[0060] Stir 3g of LPAN solution (molecular weight: 25,000) at 200°C for 100h to form a microcyclized LPAN solution, then heat-treat the microcyclized LPAN solution at 200°C for 10h to form a thermally oxidized polyacrylonitrile oligomer with a ladder structure (OPAN) solid, add 7.6g nickel oxide, 15ml solvent, and ball mill the sample with a planetary ball mill, the ball to material ratio is 7:1, 500rad / min ball mill for 10h, after discharging, dry in an oven at 230°C for 3h to obtain the thermal oxidation precursor (That is, low temperature carbonization precursor coated nickel compound). The thermal oxidation precursor was placed in a porcelain boat, under the protection of an inert atmosphere, the gas flow rate was 150ml / min, calcined at 700°C for 4h, and cooled to room temperature to obtain a graphene-coated nickel magnetic nanoparticle composite.

[0061] Compared with the traditional synthesis method, the present invention adopts the production method of graphene-coated ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com