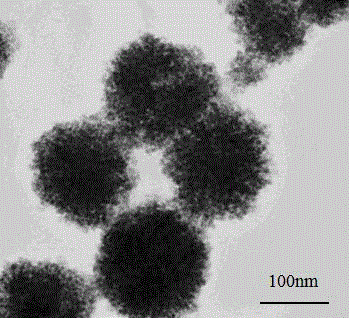

Preparation method for biocompatible magnetic microspheres collaboratively modified by two macromolecules

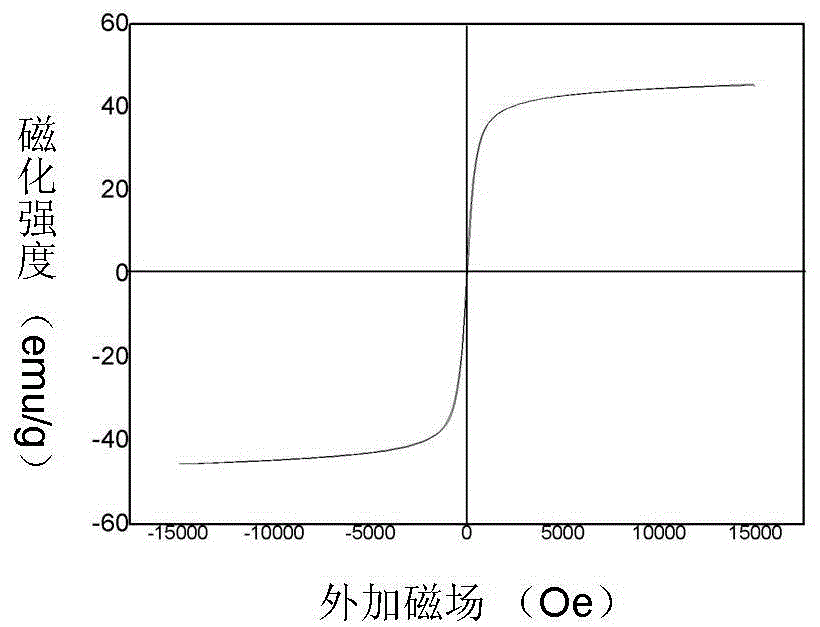

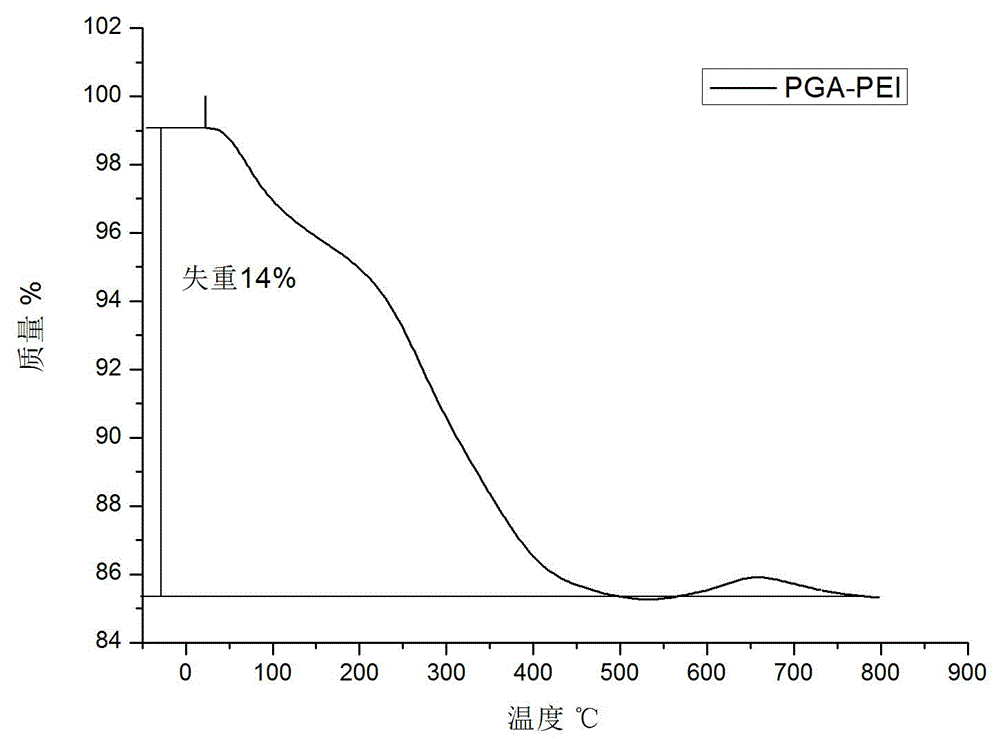

A technology of biocompatibility and magnetic microspheres, which is applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve problems such as blanks in the technical field, and achieve simple preparation methods and high particle size Uniform distribution and improved adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] 1. Accurately weigh 0.32g γ-PGA into a three-necked flask, add ethylene glycol, and heat and stir at 70°C for 20min in a heating mantle;

[0026] 2. Accurately weigh 0.15g of PEI with a molecular weight of 10,000 in a centrifuge tube, add ethylene glycol, and sonicate until completely dissolved;

[0027] 3. Accurately weigh 0.579g FeCl 3 ·6H 2 O, 1.5g of ammonium acetate is dissolved in ethylene glycol, ultrasonically dispersed evenly, after adding the mixture in step 2, continue ultrasonically dispersed evenly.

[0028] 4. Add the mixed solution in step 3 to the system in step 1, blow in nitrogen, and stir for 1 hour at 160°C;

[0029] 5. After step 4 is completed, quickly add the mixed solution into the reaction kettle, the heating temperature is 220°C, and the reaction time is 16.5 hours to obtain a composite magnetic microsphere solution;

[0030] 6. Disperse the inorganic magnetic microsphere solution obtained in step 5 in alcohol, apply ultrasound for 10 minute...

Embodiment 2

[0032] 1. Accurately weigh 0.214g of chitosan into a three-necked flask, add ethylene glycol, and heat and stir at 60°C for 30min in a heating mantle;

[0033] 2. Accurately weigh 0.15g of PEI with a molecular weight of 1800 in a centrifuge tube, add ethylene glycol agent, and sonicate until completely dissolved;

[0034] 3. Accurately weigh 0.579g Fe(NO 3 ) 3 1.5g of ammonium carbonate was dissolved in ethylene glycol, ultrasonically dispersed evenly, after adding the mixture in step 2, continued ultrasonically dispersed evenly.

[0035] 4. Add the mixed solution in step 3 to the system in step 1, blow in nitrogen, and stir for 1.5 hours at 120°C;

[0036] 5. After step 4 is completed, quickly add the mixed solution into the reaction kettle, heat at 200°C, and react for 24 hours to obtain a composite magnetic microsphere solution;

[0037] 6. Disperse the inorganic magnetic microsphere solution obtained in step 5 in alcohol, apply ultrasound for 15 minutes, use a magnetic ...

Embodiment 3

[0039] 1. Accurately weigh 0.214 γ-PGA into a three-necked flask, add ethylene glycol, and heat and stir at 60°C in a heating mantle for 20 minutes;

[0040]2. Accurately weigh 0.15g of PEI with a molecular weight of 1800 in a centrifuge tube, add ethylene glycol, and sonicate until completely dissolved;

[0041] 3. Accurately weigh 0.579g FeCl 3 ·6H 2 O. Dissolve 1.5g of ammonium acetate in ethylene glycol and disperse evenly by ultrasonic. After adding the mixture in step 2, continue to disperse evenly by ultrasonic.

[0042] 4. Add the mixed solution in step 3 to the system in step 1, blow in nitrogen, and stir for 1 hour at 160°C;

[0043] 5. After step 4 is completed, quickly add the mixed solution into the reaction kettle, the heating temperature is 190°C, and the reaction time is 12 hours to obtain a composite magnetic microsphere solution;

[0044] 6. Disperse the inorganic magnetic microsphere solution obtained in step 5 in alcohol, apply ultrasonication for 5 minu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com