Vacuum freeze-dried gypsophila stems and leaves products and preparation process thereof

A technology of vacuum freeze-drying and preparation technology, which is applied in food preservation, fruit and vegetable fresh-keeping, food science, etc. It can solve the problems of old stems and leaves, rough taste, unfit for consumption, etc., achieve good color, less loss of vitamin C, and convenient saved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

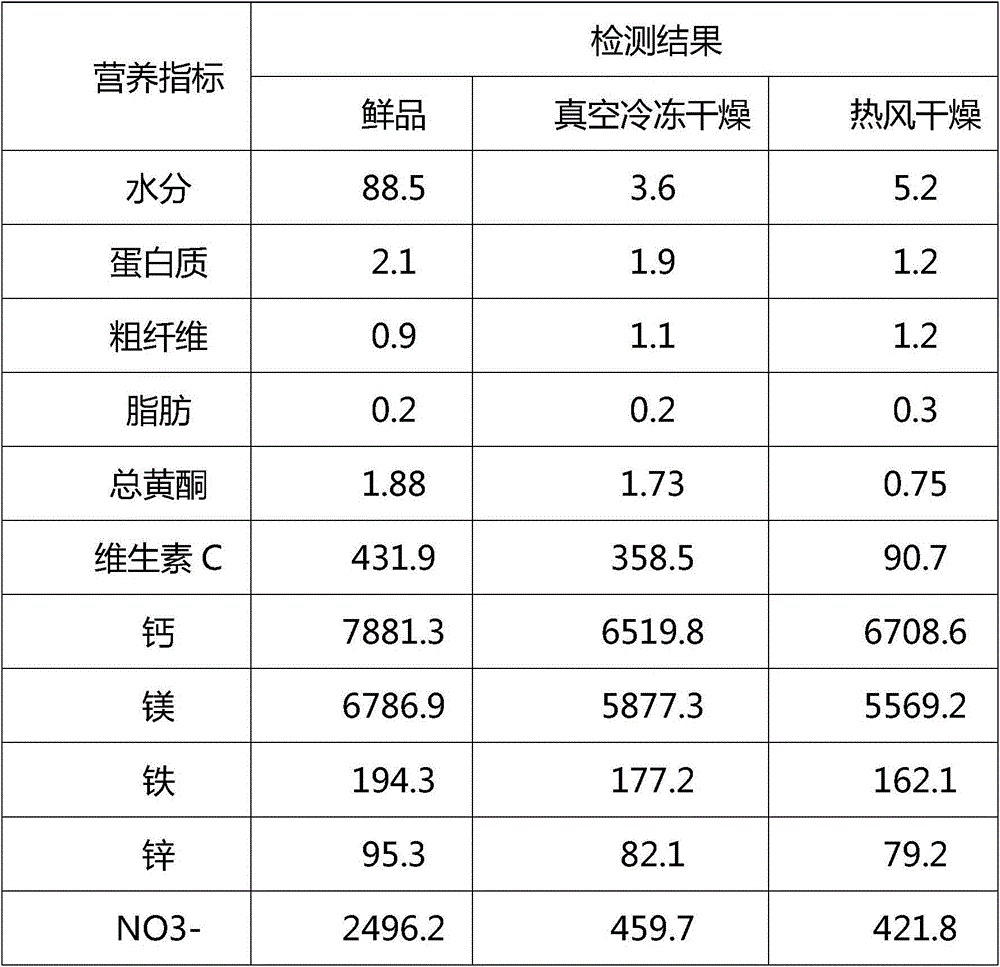

Image

Examples

Embodiment 1

[0038] A vacuum freeze-dried carnation stem and leaf product, which is obtained from fresh and tender carnation stems and leaves after pretreatment, pre-freezing, sublimation, analysis and drying, and packaging. Water, its production process includes the following steps:

[0039] (1) Pretreatment: choose fresh carnation stems and leaves as raw materials, remove yellow leaves and rotten leaves, because the stems and leaves of carnations are about 4cm long, no need to cut them, wash them with water for 3 times, and scald them at 90°C for 2 minutes to remove them. Soak in cold water to cool, drain and spread on a plate with a thickness of 15mm;

[0040] (2) Pre-freezing: Freeze the carnation stems and leaves in a plate at -30°C for 2 hours, transfer them to a freeze dryer that has been pre-cooled at -30°C, and continue to pre-freeze for 1 hour;

[0041] (3) Sublimation: turn on the vacuum pump, evacuate, start the heating program, heat until the plate temperature is 20°C, and su...

Embodiment 2

[0047] A vacuum freeze-dried carnation stem and leaf product, using fresh carnation stem and leaf as raw material, selecting fresh carnation stem and leaf as raw material, removing yellow leaves and rotten leaves to 2kg, after pretreatment, prefreezing, sublimation, analysis and drying 1. After packaging, 0.21 kg of freeze-dried carnation stems and leaves are obtained, the rehydration ratio is 5.43, and it is emerald green. It can be rehydrated in 70-80°C hot water for 50 seconds. The production process includes the following steps:

[0048] (1) Pretreatment: choose fresh carnation stems and leaves as raw materials, remove yellow leaves and rotten leaves, because the stems and leaves of carnations are about 4cm long, no need to cut them, clean water and ultrasonic vibration for 2 minutes, then blanching at 100°C for 1.5 minutes Take out, soak in cold water to cool, drain and spread on a plate with a thickness of 18mm;

[0049] (2) Pre-freezing: Freeze the carnation stems and l...

Embodiment 3

[0056] A vacuum freeze-dried carnation stem and leaf product, using fresh carnation stem and leaf as raw material, selecting fresh carnation stem and leaf as raw material, removing yellow leaves and rotten leaves to 20kg, after pretreatment, prefreezing, sublimation, analysis and drying 2.2 kg of freeze-dried carnation stems and leaves are obtained after packaging, the rehydration ratio is 5.52, and it is emerald green. It can be rehydrated in 70-80°C hot water for 50 seconds. The production process includes the following steps:

[0057] (1) Pretreatment: choose fresh carnation stems and leaves as raw materials, remove yellow leaves and rotten leaves, because the stems and leaves of carnations are about 4cm long, no need to cut them, wash them with water for 3 times, and scald them at 95°C for 1.8 minutes to remove them , soaked in cold water to cool, drained and paved with a thickness of 20mm;

[0058] (2) Pre-freezing: Freeze the carnation stems and leaves in a plate at -28°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com