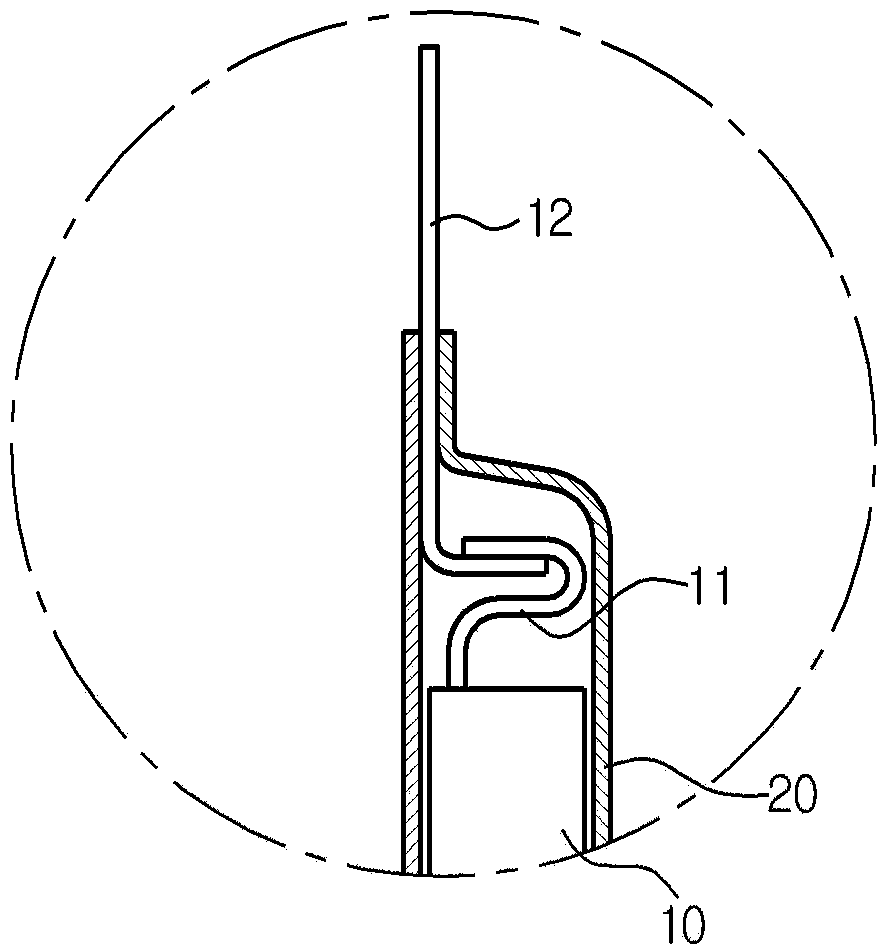

Secondary battery and method for manufacturing the same

A technology for secondary batteries and battery shells, which is applied in the manufacture of secondary batteries, secondary batteries, electrolyte storage batteries, etc., can solve the problems of heating, ignition or explosion of secondary batteries, damage to electrode assemblies 10, etc., and improve safety. , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0080] An electrolyte was prepared in which 1M LiPF 6 Dissolve in organic solvents including EC, PC and DEC and add VC, PS, FA and NA thereto, and then add PVDF-HFP as polymer particles to the obtained polymer particles in such a way that the content of the polymer particles is 10% by weight. The prepared electrolyte, from which the polymer slurry was prepared. In addition, the prepared polymer slurry was injected into a battery case accommodating the electrode assembly therein, followed by sealing, and the prepared battery case was heated at 85° C. for 2.5 hours. In this case, a pressure of 0.5 Nm was applied to the battery case using a jig press during heating. Subsequently, the heated battery case was cooled at room temperature, followed by degassing and resealing, thereby manufacturing a secondary battery according to the example.

[0081] Regarding the secondary battery manufactured according to the examples, a 3-point bending test was performed at room temperature at a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com