Thin film transistor, array substrate and display device

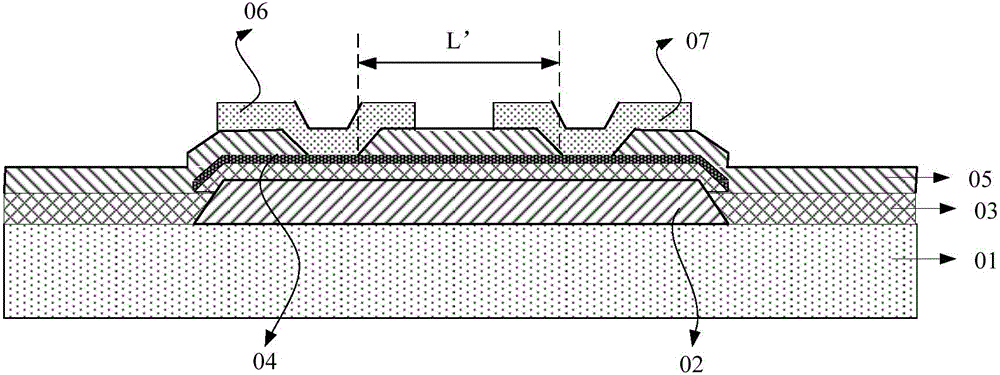

A technology of thin film transistors and array substrates, applied in the field of liquid crystal display, can solve the problems of long channel length and low working efficiency of thin film transistors, and achieve the effects of shortening charging time, improving working efficiency and reducing area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

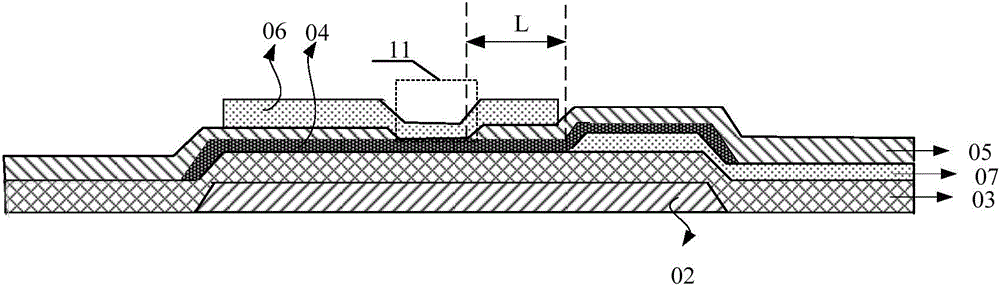

[0048] This embodiment provides a kind of thin film transistor, its structural diagram is as follows figure 2 As shown, including the gate 02, the source 07, the drain 06 and the semiconductor layer 04, the source 07 and the drain 06 are arranged in different layers, the semiconductor layer 04 is electrically connected to the source 07 and the drain 06 respectively, and the semiconductor layer 04 The region between the corresponding source 07 and the drain 06 is the channel region.

[0049] Since the source and the drain are not in the same layer, the channel length between the source and the drain ( figure 2 The middle L represents the channel length) is greatly shortened, and the channel length can be shortened to less than 5um with the current general process precision. Shortening the channel distance can shorten the charging time, greatly improve the charging efficiency of the thin film transistor, and thus improve the working efficiency of the transistor .

[0050] Th...

Embodiment 2

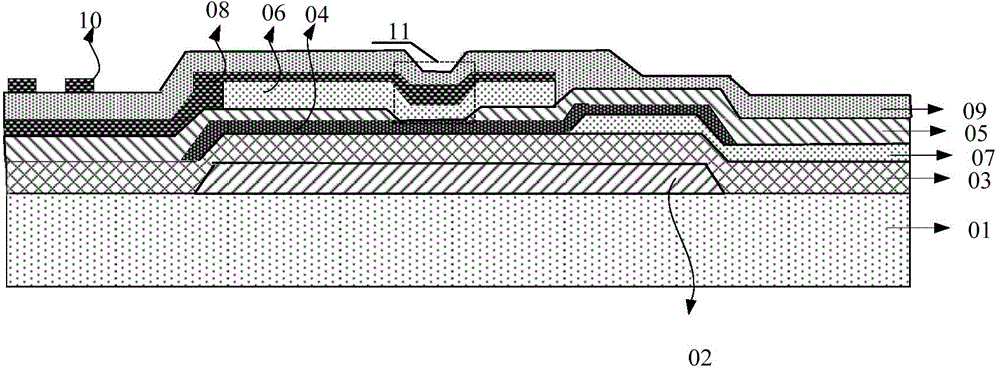

[0059] An embodiment of the present invention provides an array substrate, the structure schematic diagram is as follows image 3 As shown, it includes a base substrate 01, a thin film transistor, a pixel electrode 08, a gate line and a data line (wherein the gate line and the data line are in image 3 not shown), the thin film transistor and the gate line are arranged on the base substrate 01, and the source 07 and the drain 06 of the thin film transistor are arranged in different layers; the semiconductor layer 04 of the thin film transistor is electrically connected to the source 07 and the drain 06 respectively connection; the pixel electrode 08 is electrically connected to the drain 06 of the thin film transistor; the source 07 of the thin film transistor is electrically connected to the data line.

[0060] Preferably, the different layer settings of the source 07 and the drain 06 of the thin film transistor in this embodiment specifically include:

[0061] The source 07...

Embodiment 3

[0084] Embodiment 3 of the present invention also provides a display device, including a color filter substrate and an array substrate, wherein the array substrate is the array substrate described in Embodiment 2.

[0085] The above-mentioned display device can be: OLED panel, TV, digital photo frame, mobile phone, tablet computer and other products or components with any display function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com